Feeling lost in a sea of interview questions? Landed that dream interview for Automatic Equipment Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Automatic Equipment Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

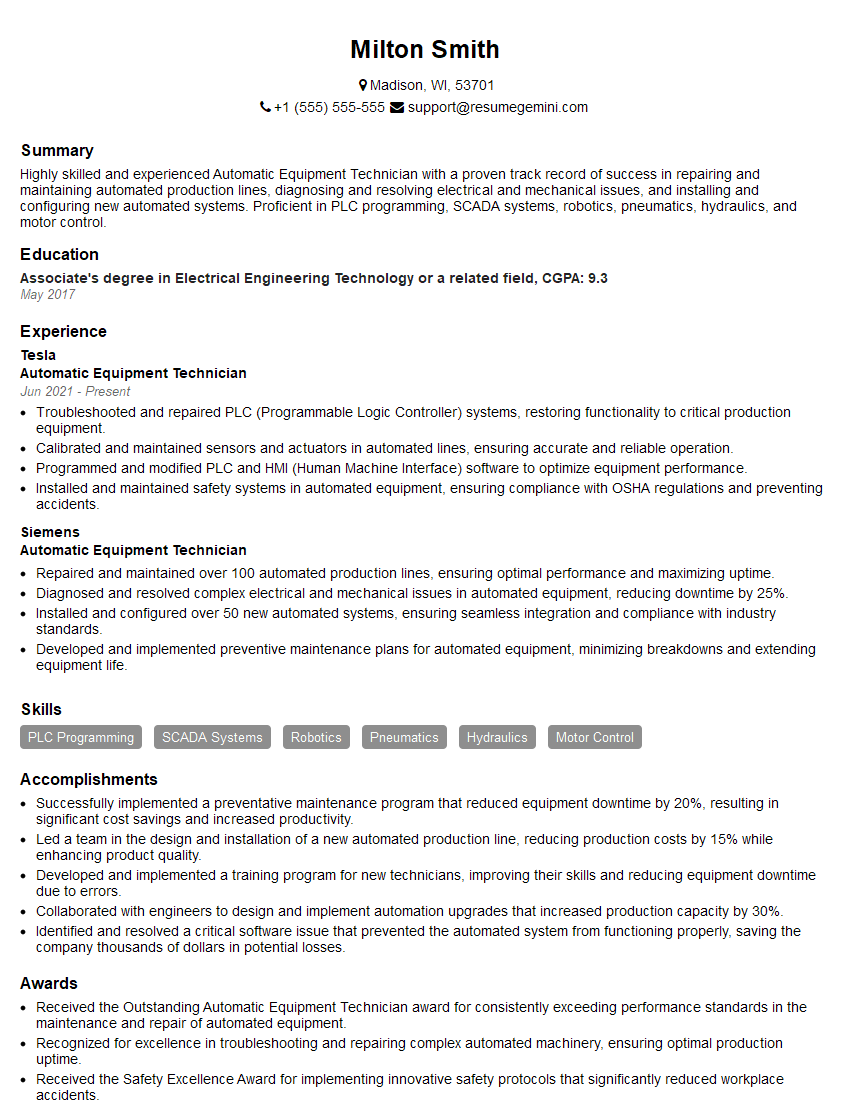

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Equipment Technician

1. What is the difference between a PLC and a DCS?

The difference between a PLC (Programmable Logic Controller) and a DCS (Distributed Control System) is in their scope and complexity. A PLC is typically used for controlling a single machine or a small group of machines, while a DCS is used for controlling a large and complex process or system.

- PLCs are typically used in smaller applications such as conveyor systems, material handling equipment, and packaging machines.

- DCSs are typically used in larger applications such as power plants, oil refineries, and chemical plants.

2. What are the different types of sensors used in automatic equipment?

Analog Sensors

- These sensors convert a physical parameter into an electrical signal that is proportional to the parameter being measured.

- These sensors are used in applications where precise measurement is required.

Digital Sensors

- These sensors convert a physical parameter into an electrical signal that is either on or off.

- These sensors are used in applications where precise measurement is not required.

Limit Switches

- These sensors detect the presence or absence of an object.

- These sensors are used in applications where the position of an object needs to be monitored.

3. What are the different types of actuators used in automatic equipment?

Actuators are devices that convert an electrical signal into a mechanical motion.

- Solenoids

- Motors

- Hydraulic cylinders

- Pneumatic cylinders

4. What are the different types of control systems used in automatic equipment?

Control systems are used to regulate the operation of automatic equipment.

- Open-loop control systems

- Closed-loop control systems

- Proportional-integral-derivative (PID) control systems

- Fuzzy logic control systems

- Neural network control systems

5. What are the different types of software used in automatic equipment?

Software is used to program and control automatic equipment.

- PLC programming software

- DCS programming software

- SCADA (Supervisory Control and Data Acquisition) software

- MES (Manufacturing Execution System) software

- ERP (Enterprise Resource Planning) software

6. What are the different types of maintenance procedures used for automatic equipment?

Maintenance procedures are used to keep automatic equipment in good working condition.

- Preventive maintenance

- Predictive maintenance

- Corrective maintenance

- Overhaul maintenance

7. What are the different types of safety devices used in automatic equipment?

Safety devices are used to protect personnel and equipment from hazards.

- Guards

- Interlocks

- Emergency stop devices

- Pressure relief valves

- Temperature sensors

8. What are the different types of troubleshooting techniques used for automatic equipment?

Troubleshooting techniques are used to identify and resolve problems with automatic equipment.

- Visual inspection

- Electrical testing

- Mechanical testing

- Software testing

- PLC program analysis

9. What are the different types of training programs available for automatic equipment technicians?

Training programs are available to help automatic equipment technicians develop the skills and knowledge they need to be successful.

- On-the-job training

- Classroom training

- Online training

- Vendor-specific training

- Certification programs

10. What are the different types of career opportunities available for automatic equipment technicians?

Automatic equipment technicians have a wide range of career opportunities available to them.

- Maintenance technician

- Project engineer

- Sales engineer

- Technical trainer

- Manager

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Equipment Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Equipment Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Equipment Maintenance and Repair

Responsible for performing scheduled and unscheduled maintenance on automated equipment, including diagnosing and repairing malfunctions.

- Conduct inspections, troubleshooting problems, and replacing or repairing defective parts.

- Maintain and service automated systems, including robots, conveyors, and machines.

2. Equipment Calibration and Programming

Calibrate and program automated equipment to ensure accuracy and efficiency.

- Use specialized software and diagnostic tools to diagnose and troubleshoot equipment issues.

- Develop and implement maintenance procedures to optimize equipment performance.

3. Electrical and Mechanical Troubleshooting

Troubleshoot electrical and mechanical issues on automated equipment.

- Identify and repair electrical faults, loose connections, and mechanical breakdowns.

- Maintain and repair control systems, including PLCs, HMIs, and sensors.

4. Process Optimization and Efficiency

Analyze and optimize automated processes to improve efficiency and reduce downtime.

- Identify and implement improvements to reduce cycle times and increase productivity.

- Monitor equipment performance and identify areas for improvement.

Interview Tips

1. Research the Company and Position

Thoroughly research the company and the specific position to gain insights into their operations, industry, and culture.

- Visit the company website, read industry news, and connect with employees on LinkedIn.

- Identify key requirements of the role and align your skills and experience accordingly.

2. Prepare for Technical Questions

Expect technical questions related to automated equipment maintenance, repair, and troubleshooting.

- Review basic electrical and mechanical concepts, such as Ohm’s law, torque, and power.

- Practice troubleshooting scenarios and demonstrate your problem-solving abilities.

3. Showcase Your Soft Skills

Highlight your soft skills, such as communication, teamwork, and problem-solving, as they are equally important in this role.

- Provide examples of projects where you collaborated effectively with colleagues.

- Discuss situations where you resolved technical challenges through creative solutions.

4. Prepare Questions for the Interviewer

Preparing thoughtful questions for the interviewer shows interest and engagement.

- Ask about the company’s growth plans and how the position contributes to those goals.

- Inquire about the company’s commitment to employee development and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automatic Equipment Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!