Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electric Motor Fitter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

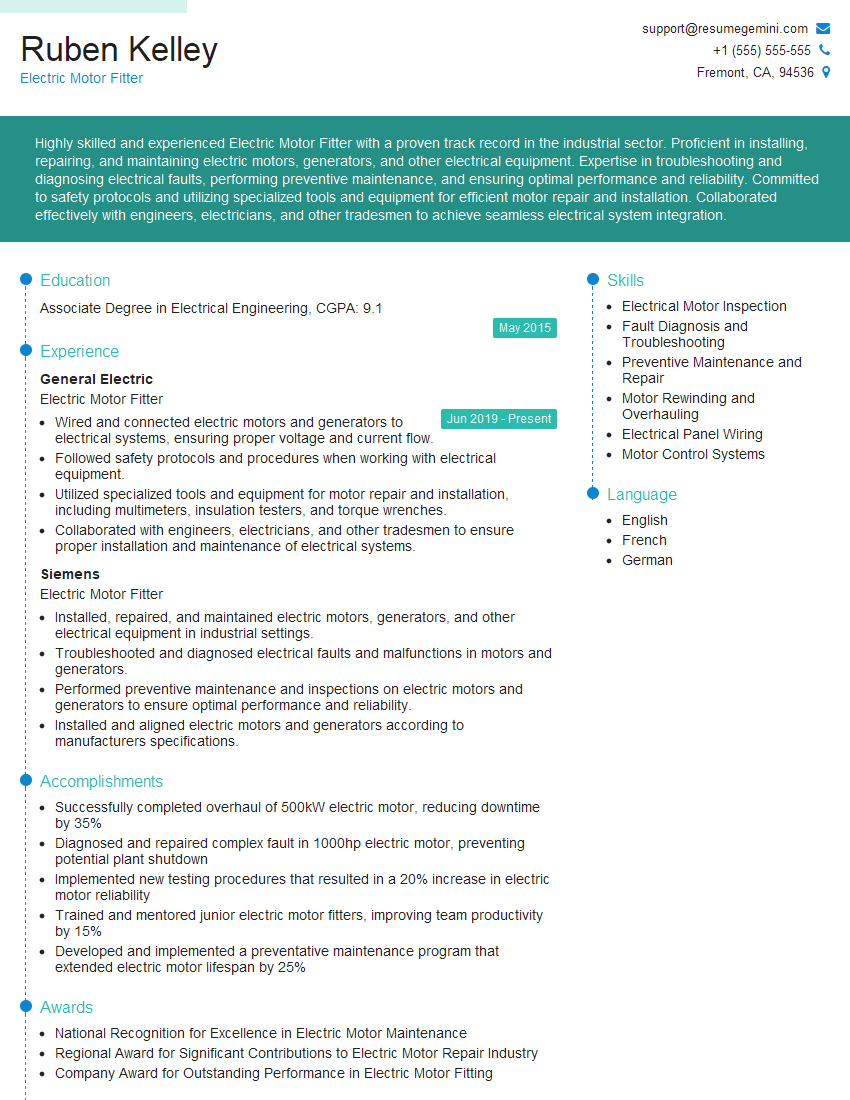

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Motor Fitter

1. Explain the procedure for installing an electric motor?

The procedure for installing an electric motor involves the following steps:

- Check the motor’s nameplate to ensure it matches the application requirements.

- Select and install the appropriate mounting hardware.

- Connect the motor’s electrical leads to the power supply.

- Align the motor’s shaft with the driven load.

- Secure the motor to the mounting hardware.

- Test the motor’s operation by running it at no load.

2. How do you troubleshoot an electric motor that is not running?

Check the power supply

- Ensure that the power supply is turned on.

- Check the fuses or circuit breakers to ensure they are not blown or tripped.

- Measure the voltage at the motor’s terminals to ensure it is within the specified range.

Check the motor’s connections

- Ensure that the motor’s electrical leads are properly connected to the power supply.

- Tighten any loose connections.

- Check for any damaged or frayed wires.

Check the motor’s bearings

- Listen for any unusual noises coming from the motor.

- Check the motor’s bearings for any signs of wear or damage.

- Lubricate the bearings if necessary.

Check the motor’s windings

- Measure the resistance of the motor’s windings to ensure they are within the specified range.

- Check for any open or shorted windings.

- If necessary, replace the motor’s windings.

3. What are the different types of electric motors?

There are various types of electric motors, each with its own advantages and applications:

- AC motors: These motors operate on alternating current and are commonly used in industrial applications

- DC motors: These motors operate on direct current and are often used in automotive and household appliances.

- Brushless motors: These motors use electronic commutation instead of brushes and are known for their high efficiency and long lifespan.

- Stepper motors: These motors move in discrete steps and are often used in precision positioning applications.

- Servo motors: These motors are high-performance motors that are used in applications requiring precise control of speed and position.

4. What are the key factors to consider when selecting an electric motor?

When selecting an electric motor, several key factors should be considered:

- Power requirements: Determine the power output required for the application.

- Speed: Consider the desired operating speed of the motor.

- Torque: Determine the required torque output of the motor.

- Duty cycle: Consider the duration and frequency of the motor’s operation.

- Environmental conditions: Consider the operating environment, including temperature, humidity, and vibration.

- Cost: Determine the budget available for the motor.

- Reliability: Consider the importance of reliability for the application.

- Efficiency: Consider the energy efficiency of the motor.

- Maintenance: Consider the maintenance requirements and accessibility of the motor.

5. How do you maintain an electric motor?

Regular maintenance is crucial to ensure the optimal performance and lifespan of an electric motor:

- Clean the motor regularly to remove dust, dirt, and debris.

- Lubricate the motor’s bearings according to the manufacturer’s recommendations.

- Check the motor’s electrical connections for any loose or damaged wires.

- Monitor the motor’s temperature and noise levels during operation.

- Perform periodic inspections and testing to identify any potential issues early on.

6. What safety precautions should be taken when working with electric motors?

When working with electric motors, it is essential to prioritize safety:

- Always disconnect the power supply before working on the motor.

- Wear appropriate personal protective equipment, including safety glasses, gloves, and earplugs.

- Use insulated tools and equipment.

- Be aware of the potential for electrical shock and burns.

- Follow lockout/tagout procedures when servicing the motor.

7. What are the common causes of electric motor failure?

Electric motors can fail due to various reasons:

- Overheating: Excessive heat can damage the motor’s insulation and windings.

- Bearing failure: Worn or damaged bearings can cause excessive friction and heat.

- Electrical faults: Short circuits, open circuits, or ground faults can damage the motor’s windings.

- Mechanical stress: Excessive vibration, shock, or misalignment can damage the motor’s components.

- Environmental factors: Exposure to moisture, dust, or corrosive chemicals can deteriorate the motor’s components.

8. How do you test an electric motor to ensure it is functioning properly?

Testing an electric motor involves several steps:

- Insulation resistance test: This test measures the resistance between the motor’s windings and the frame to ensure proper insulation.

- Hi-pot test: This test applies a high voltage to the motor’s windings to check for any electrical breakdown.

- Continuity test: This test checks for continuity in the motor’s windings, ensuring that there are no open circuits.

- Load test: This test involves running the motor under load to verify its performance and identify any potential issues.

9. What are the different methods used to control the speed of an electric motor?

There are several methods to control the speed of an electric motor:

- Variable frequency drive (VFD): A VFD adjusts the frequency of the power supply to the motor, varying its speed.

- Brushless DC motor: These motors use electronic commutation to control the speed without the use of brushes.

- Stepper motor: These motors move in discrete steps, allowing for precise speed control.

- Servo motor: These motors use feedback control to achieve precise speed and position control.

10. How do you determine the efficiency of an electric motor?

The efficiency of an electric motor is measured as the ratio of its output power to its input power:

- Input power: This is the electrical power supplied to the motor.

- Output power: This is the mechanical power produced by the motor.

- Efficiency: Efficiency = (Output power / Input power) x 100%

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Motor Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Motor Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electric Motor Fitters have a wide range of responsibilities that involve using their knowledge of electrical motors to complete tasks related to installation, maintenance, and repairs. Their duties may include:1. Installation and Assembly

Reading and understanding blueprints and technical drawings to ensure proper installation.

- Positioning and mounting motors.

- Connecting motors to power sources and drive mechanisms.

2. Maintenance and Inspections

Conducting regular inspections and performing preventive maintenance tasks to ensure optimal motor performance.

- Checking and cleaning motor components.

- Lubricating and adjusting moving parts.

3. Troubleshooting and Repair

Diagnosing and resolving motor malfunctions through testing and analysis.

- Identifying and replacing faulty components.

- Rewinding and rewiring motors.

4. Documentation and Reporting

Keeping detailed records of maintenance activities, repairs, and inspections for reference and future planning.

- Creating work orders and invoices.

- Reporting on motor performance and maintenance needs.

Interview Tips

Interview Preparation Tips for Electric Motor Fitter candidates can help them showcase their skills, experience, and suitability for the role. Here are some tips to help you ace the interview:1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Electric Motor Fitter position you are applying for.

- Visit the company’s website to learn about their products, services, and culture.

- Review the job description to gain a clear understanding of the responsibilities and qualifications required for the role.

2. Prepare Answers to Common Interview Questions

Practice answering common interview questions related to your skills, experience, and knowledge of electric motors.

- Explain your experience in installing, maintaining, and repairing electric motors.

- Describe your understanding of electrical motor principles, including troubleshooting techniques.

3. Highlight Your Experience and Skills

During the interview, confidently highlight your relevant experience and skills that align with the job requirements.

- Quantify your accomplishments using specific examples and metrics whenever possible.

- Emphasize your ability to work independently, as well as your teamwork and communication skills.

4. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer that demonstrate your interest in the role and the company.

- Ask about the company’s growth plans and how the Electric Motor Fitter role fits into those plans.

- Inquire about opportunities for professional development and training within the organization.

5. Dress Professionally and Arrive on Time

Make a positive impression by dressing professionally and arriving on time for your interview.

- Wear clean and pressed clothing that is appropriate for an office setting.

- Be punctual and plan to arrive at the interview location with ample time to spare.

6. Be Enthusiastic and Confident

Throughout the interview, maintain a positive and enthusiastic attitude that reflects your interest in the position.

- Demonstrate your confidence in your abilities, but be humble and respectful of the interviewer’s time.

- If you have any questions, ask them clearly and professionally.

7. Practice and Seek Feedback

Practice answering interview questions with a friend, family member, or career counselor to gain feedback.

- Record yourself answering questions to identify areas for improvement.

- Seek feedback from others to enhance your communication and presentation skills.

8. Follow Up After the Interview

Within 24 hours of the interview, send a thank-you note to the interviewer, reiterating your interest in the position.

- Reiterate your key qualifications and how they align with the company’s needs.

- Express your gratitude for the opportunity to interview and inquire about the next steps in the hiring process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electric Motor Fitter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.