Are you gearing up for an interview for a Electric Motor Tester Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Electric Motor Tester Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

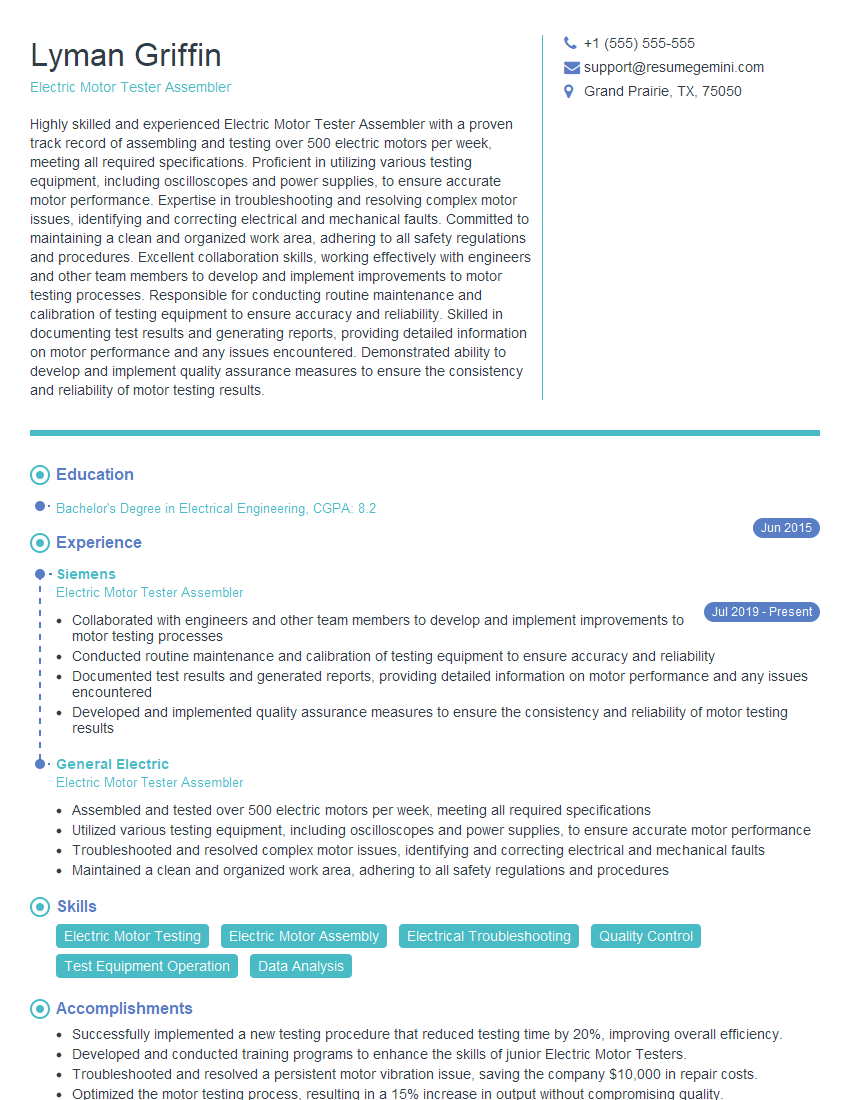

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Motor Tester Assembler

1. Explain the process of assembling an electric motor tester?

The process of assembling an electric motor tester involves several steps:

- Gather the necessary components, including the motor, tester housing, wiring, and any additional accessories.

- Mount the motor inside the housing, ensuring it is securely fastened and aligned properly.

- Connect the motor to the tester’s wiring, following the provided schematics.

- Install any additional components, such as sensors, displays, or control panels.

- Calibrate the tester according to the manufacturer’s specifications, using specialized equipment.

- Perform initial testing to verify the tester’s functionality and accuracy.

2. What are the key factors to consider when testing electric motors?

Input voltage and current:

Ensuring the motor operates within its specified voltage and current ranges.Speed and torque:

Measuring the motor’s rotational speed and torque output under different load conditions.Efficiency:

Determining the motor’s energy efficiency by calculating the ratio of output power to input power.Temperature:

Monitoring the motor’s temperature during operation to prevent overheating.Noise and vibration:

Assessing the motor’s noise and vibration levels to ensure they meet acceptable standards.

3. Describe the different types of electric motor testing equipment?

There are various types of electric motor testing equipment, including:

Dynamometers:

Used to measure motor torque, speed, and power output.Tachometers:

Used to measure motor speed.Power analyzers:

Used to measure electrical power and efficiency.Temperature probes:

Used to monitor motor temperature.Vibration analyzers:

Used to measure motor vibration levels.

4. Explain the safety precautions that should be taken when testing electric motors?

Safety is paramount when testing electric motors:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and ear protection.

- Ensure the test area is well-ventilated and free from flammable materials.

- Inspect the motor and testing equipment for any damage or defects before use.

- Follow the manufacturer’s instructions for safe operation of the testing equipment.

- Never touch live electrical components or moving parts.

5. How do you troubleshoot common problems encountered during electric motor testing?

Motor not starting:

Check power supply, wiring connections, and motor brushes.Motor running slowly or overheating:

Check for mechanical issues, such as bearing wear or shaft misalignment.Excessive noise or vibration:

Check for unbalanced components, loose parts, or worn bearings.Motor tripping on overload:

Check for excessive load, voltage fluctuations, or insulation breakdown.Incorrect speed or torque readings:

Calibrate the testing equipment and inspect for sensor malfunctions.

6. Describe the importance of documentation in electric motor testing?

Thorough documentation is crucial in electric motor testing for:

- Recording test results and conditions for future reference.

- Providing evidence of the motor’s performance and compliance with specifications.

- Facilitating troubleshooting and failure analysis.

- Meeting quality control and regulatory requirements.

- Sharing test data with customers or other stakeholders.

7. What are the latest trends and advancements in electric motor testing technology?

Automated testing systems:

Using software and robotics to automate test procedures, reducing human error.Non-invasive testing techniques:

Utilizing sensors and analytics to monitor motor performance without disassembling it.Remote monitoring:

Enabling real-time data collection and analysis of motors in operation.Predictive maintenance:

Employing sensors and algorithms to identify potential motor failures early on.Virtual reality (VR) and augmented reality (AR):

Facilitating interactive visualization and troubleshooting of motor systems.

8. How do you stay up-to-date with the latest developments in electric motor testing?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Participating in online forums and webinars.

- Seeking training and certification from manufacturers.

- Networking with other professionals in the field.

9. What motivates you to pursue a career as an Electric Motor Tester Assembler?

I am passionate about electric motors and their vital role in various industries. The opportunity to work with these advanced devices and ensure their reliable operation motivates me to pursue this career.

10. How do you handle working in a fast-paced and demanding environment?

In fast-paced environments, I thrive on the challenge of balancing efficiency and accuracy. I prioritize tasks, communicate effectively, and seek support when needed. I am adaptable, flexible, and eager to meet deadlines without compromising quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Motor Tester Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Motor Tester Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electric Motor Tester Assemblers play a crucial role in the production and quality assurance of electric motors. Their key responsibilities include:

1. Motor Assembly and Testing

Assemble electric motors according to specifications and quality standards.

- Install components such as windings, bearings, and housings.

- Verify assembly accuracy and functionality through visual inspections and testing.

2. Electrical and Mechanical Testing

Conduct various tests to evaluate the electrical and mechanical performance of motors.

- Perform electrical tests such as insulation resistance, voltage withstand, and continuity checks.

- Conduct mechanical tests like run-in, load, and vibration analysis to ensure proper motor operation.

3. Data Analysis and Troubleshooting

Analyze test results to identify performance deviations and troubleshoot issues.

- Interpret data from testing equipment to assess motor characteristics.

- Identify and resolve assembly or performance problems.

4. Record Keeping and Documentation

Maintain accurate records and documentation related to motor assembly and testing.

- Complete assembly and test reports, including details of materials used, test results, and any deviations.

- Ensure compliance with quality standards and industry best practices.

Interview Tips

To prepare for an Electric Motor Tester Assembler interview, it’s essential to:

1. Research the Company and Position

Familiarize yourself with the company’s products, industry, and values.

- Visit the company’s website and social media pages.

- Review the job description thoroughly to understand the specific requirements.

2. Highlight Relevant Experience and Skills

Emphasize your experience in motor assembly, electrical testing, and mechanical analysis.

- Quantify your achievements using specific metrics and examples.

- Prepare a portfolio or resume that showcases your technical abilities.

3. Practice Answer Common Interview Questions

Prepare for questions that assess your technical knowledge, problem-solving skills, and attention to detail.

- Example Question: Describe your experience in troubleshooting electrical motor problems.

- Example Answer: “In a previous role, I successfully resolved a recurring issue with motor overheating by identifying a faulty component and implementing a design modification.”

4. Be Prepared to Discuss Industry Knowledge and Trends

Show your understanding of the electric motor industry and its advancements.

- Read industry publications and attend trade shows to stay updated.

- Be ready to share your insights on emerging technologies and their potential impact on motor production.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electric Motor Tester Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.