Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Electric Motor Rewinder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Electric Motor Rewinder so you can tailor your answers to impress potential employers.

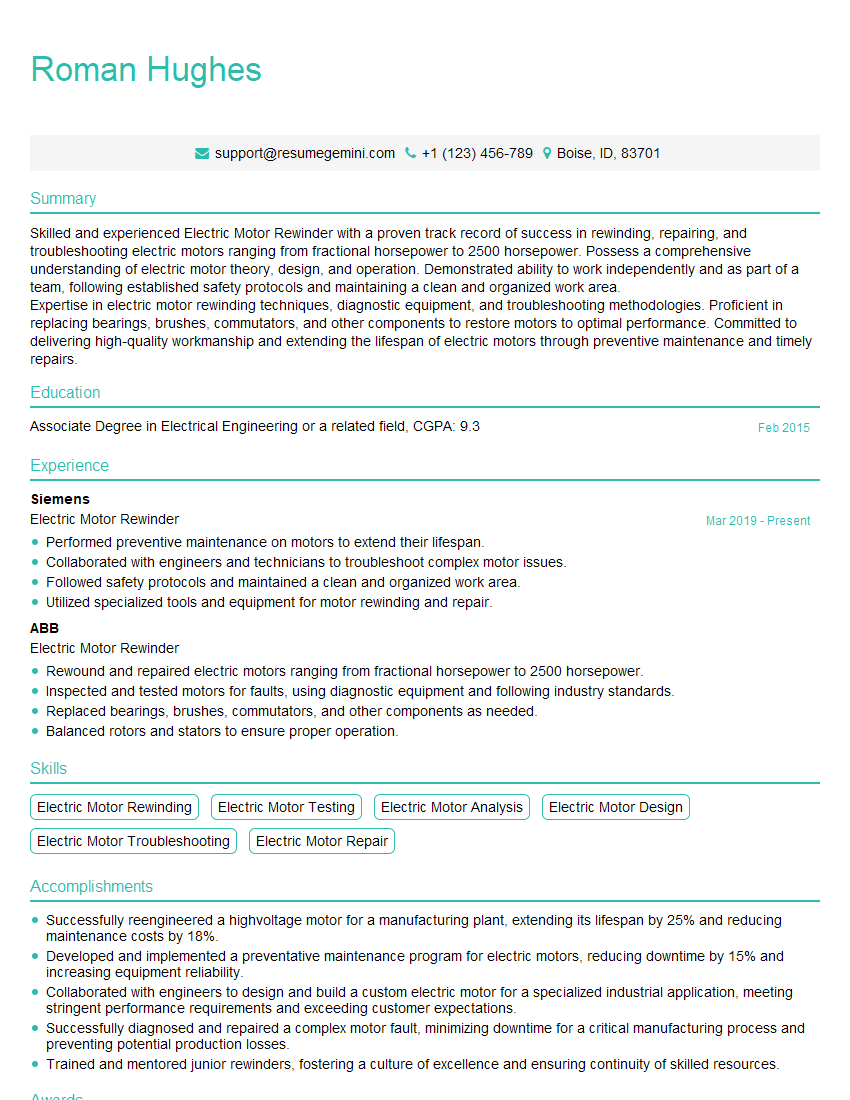

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Motor Rewinder

1. What are the different types of electric motors and their applications?

Sample Answer:

- DC Motors: Used in applications requiring high torque at low speeds, such as electric vehicles, power tools, and industrial machinery.

- AC Motors: Commonly used in industrial and commercial applications due to their high efficiency and reliability, including induction motors, synchronous motors, and stepper motors.

- Brushless Motors: Utilize electronic commutation to eliminate wear and noise, making them ideal for high-speed applications such as fans, pumps, and robotics.

- Servo Motors: Designed for precise positioning and motion control in industrial automation and robotics.

- Linear Motors: Generate linear motion directly, used in applications like high-speed packaging and transportation systems.

2. What are the key components of an electric motor and their functions?

Sample Answer:

Stator:

- Stationary part that creates a magnetic field.

- Consists of laminated steel core with slots to hold stator windings.

Rotor:

- Rotating part that interacts with the stator’s magnetic field to produce torque.

- Can have different types of windings, such as squirrel-cage or wound-rotor.

Windings:

- Conductors that carry electric current to create the magnetic fields.

- Can be connected in different configurations to achieve desired motor characteristics.

Bearings:

- Support the rotor as it rotates.

- Can be ball bearings, roller bearings, or sleeve bearings.

3. Describe the process of troubleshooting an electric motor.

Sample Answer:

- Visual Inspection: Check for physical damage, loose connections, or contamination.

- Electrical Tests: Perform insulation resistance tests, continuity checks, and voltage measurements to identify electrical faults.

- Mechanical Tests: Check for bearing noise, vibration, or misalignment that could indicate mechanical issues.

- Load Testing: Connect the motor to a load and observe its performance under different conditions to diagnose torque and speed issues.

- Thermal Monitoring: Measure temperatures using thermal imaging or temperature sensors to identify overheating or cooling problems.

4. How do you determine the appropriate motor replacement for a specific application?

Sample Answer:

- Power Requirements: Determine the torque and speed requirements based on the application’s load and operating conditions.

- Voltage and Frequency: Ensure the motor is compatible with the available power supply.

- Mounting and Size: Consider the physical space constraints and the desired mounting configuration.

- Efficiency and Reliability: Evaluate the motor’s energy efficiency rating and expected lifespan to optimize energy costs and maintenance intervals.

- Environmental Conditions: Choose a motor suitable for the operating environment, such as extreme temperatures, moisture, or corrosive atmospheres.

5. What are the safety precautions to observe when working with electric motors?

Sample Answer:

- Lockout/Tagout: Isolate the motor from power sources before performing any maintenance or repairs.

- Proper Grounding: Ensure proper grounding of the motor and equipment to prevent electrical accidents.

- Wear Appropriate PPE: Use insulated gloves, safety glasses, and protective clothing to minimize electrical and mechanical hazards.

- Avoid Touching Live Parts: Never touch live terminals or moving parts while the motor is running.

- Follow Manufacturer’s Instructions: Refer to the motor’s documentation for specific safety guidelines and maintenance procedures.

6. How do you balance the armature of a DC motor?

Sample Answer:

- Mechanical Balancing: Use a balancing machine or knife-edge fixture to locate and drill holes in the armature to achieve proper weight distribution.

- Dynamic Balancing: Attach the armature to a balancing stand and rotate it at operating speed while measuring vibrations. Add or remove weights as necessary to reduce vibration levels.

7. What are the key indicators of a faulty electric motor?

Sample Answer:

- Overheating: Excessive temperatures caused by overloading, poor ventilation, or insulation breakdown.

- Unusual Noise or Vibration: Abnormal sounds or excessive vibrations may indicate bearing wear, misalignment, or armature imbalance.

- Reduced Torque or Speed: Inability to produce the desired torque or speed may result from electrical faults, mechanical issues, or load imbalances.

- Arcing or Sparking: Electrical arcing or sparking can occur due to insulation damage, loose connections, or brush wear.

- Electrical Faults: Ground faults, short circuits, or open circuits can lead to motor failure or safety hazards.

8. How do you rewind the stator of an AC induction motor?

Sample Answer:

- Remove and Disassemble: Disconnect the motor, remove the stator from its housing, and disassemble the stator windings.

- Cleaning and Preparation: Clean the stator slots and remove any insulation residue or contaminants.

- Winding the Stator: Using a winding machine or hand-winding technique, wind the new coils into the stator slots according to the manufacturer’s specifications.

- Insulating and Connecting: Insulate the windings and connect them to the appropriate terminals based on the motor’s winding diagram.

- Testing and Reassembly: Perform electrical tests to verify the windings and reassemble the stator into the motor housing.

9. What is the significance of slot insulation in an electric motor?

Sample Answer:

- Electrical Insulation: Prevents short circuits between the stator windings and the core.

- Mechanical Support: Provides structural support to the windings and reduces vibration.

- Heat Dissipation: Allows heat generated by the windings to dissipate into the motor housing.

- Moisture Protection: Prevents moisture from penetrating the windings, which can cause insulation breakdown.

- Noise Reduction: Reduces slot noise generated by the windings vibrating against the stator core.

10. How do you troubleshoot a single-phase induction motor that fails to start?

Sample Answer:

- Check Power Supply: Ensure the motor is receiving power and verify the voltage and frequency.

- Inspect Centrifugal Switch: Inspect the centrifugal switch for proper operation and clean or replace if necessary.

- Check Starting Capacitor: Measure the capacitance of the starting capacitor and replace if its value has significantly decreased.

- Test Run Capacitor: Similarly, check the capacitance of the run capacitor and replace if faulty.

- Examine Motor Windings: Perform electrical tests to identify any open circuits or short circuits in the stator or rotor windings.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Motor Rewinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Motor Rewinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electric Motor Rewinders are responsible for repairing and maintaining electric motors. They perform a variety of tasks, including:

1. Inspecting and diagnosing motor problems

Rewinders diagnose electrical issues, mechanical failures, and other problems using a variety of diagnostic techniques.

- Identify the source of the problem

- Determine the best course of action for repair

2. Disassembling and cleaning motors

Rewinders remove parts, clean components, and inspect for damage.

- Disassemble the motor to identify the source of the problem

- Clean components and inspect for damage

3. Rewinding and replacing faulty coils

Rewinders replace or repair faulty coils, ensuring the motor operates efficiently.

- Remove the old coils from the motor

- Wind new coils to replace the old ones

4. Reassembling and testing motors

Rewinders reassemble motors and test them to ensure they are functioning properly

- Reassemble the motor and reconnect the wires

- Test the motor to ensure it is functioning properly

Interview Tips

To prepare for an interview, Electric Motor Rewinders should:

1. Research the company and the position

Understanding the company’s mission, values, and the specific responsibilities of the role will help you tailor your answers and demonstrate your qualifications.

- Visit the company’s website

- Read industry news and articles

2. Practice your answers to common interview questions

Prepare for questions about your experience, skills, and why you are interested in the position.

- Use the STAR method to structure your answers

- Practice your answers out loud.

3. Be prepared to discuss your experience and qualifications

Highlight your skills and experience in electric motor repair and troubleshooting.

- Provide specific examples of your work

- Quantify your accomplishments whenever possible

4. Be prepared to answer questions about your availability and schedule

Electric Motor Rewinders may be required to work flexible hours or on-call.

- Be honest about your availability

- Explain how you will manage your schedule if needed

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electric Motor Rewinder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.