Feeling lost in a sea of interview questions? Landed that dream interview for Hydrostatic Tubing Tester but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hydrostatic Tubing Tester interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

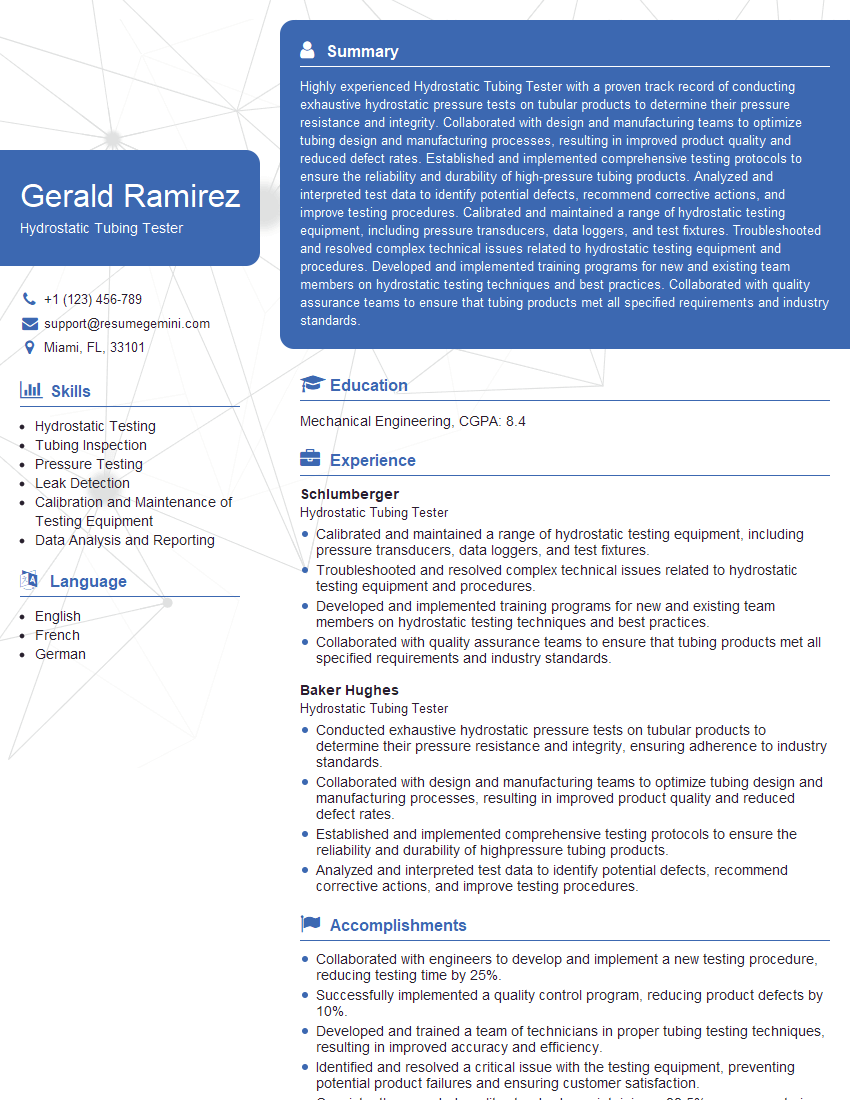

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydrostatic Tubing Tester

1. What are the different types of hydrostatic tubing tests and their purpose?

There are three main types of hydrostatic tubing tests: pressure testing, burst testing, and leak testing.

- Pressure testing is used to verify the integrity of a tube under pressure. This test is typically performed at a pressure that is slightly higher than the maximum operating pressure of the tube.

- Burst testing is used to determine the failure pressure of a tube. This test is typically performed at a pressure that is significantly higher than the maximum operating pressure of the tube.

- Leak testing is used to detect leaks in a tube. This test is typically performed at a pressure that is slightly lower than the maximum operating pressure of the tube.

2. What are the different methods of hydrostatic tubing testing?

Manual testing

- This method involves using a manual pump to pressurize the tube.

- The pressure is then held constant for a period of time to allow any leaks to be detected.

Automated testing

- This method involves using a computerized system to pressurize the tube and monitor the pressure.

- The system can be programmed to perform a variety of test cycles, including pressure testing, burst testing, and leak testing.

Immersion testing

- This method involves immersing the tube in a liquid and then pressurizing the liquid.

- The pressure is then held constant for a period of time to allow any leaks to be detected.

3. What are the advantages and disadvantages of hydrostatic tubing testing?

Advantages

- Hydrostatic tubing testing is a relatively simple and inexpensive method of testing tubes.

- It can be used to test a variety of different types of tubes, including metal, plastic, and composite.

- It can be used to detect a variety of different types of defects, including leaks, cracks, and bulges.

Disadvantages

- Hydrostatic tubing testing can be time-consuming, especially for large or complex tubes.

- It can be difficult to control the pressure accurately, which can lead to false positives or false negatives.

- It can be dangerous, especially if the tube fails under pressure.

4. What are the different factors that can affect the results of a hydrostatic tubing test?

- The type of tube being tested

- The size of the tube

- The material of the tube

- The test pressure

- The test duration

- The test temperature

- The test environment

- The operator

5. What are the different safety precautions that should be taken when performing a hydrostatic tubing test?

- Wear appropriate safety gear, including eye protection, ear protection, and gloves.

- Ensure that the test area is well-ventilated.

- Use a pressure relief valve to prevent the pressure from exceeding the maximum allowable pressure.

- Do not exceed the maximum allowable test pressure.

- Do not leave the test unattended.

- Be aware of the potential hazards of the test liquid.

6. What are the different troubleshooting techniques that can be used to identify the cause of a failed hydrostatic tubing test?

- Check the test setup for any errors.

- Inspect the tube for any visible defects.

- Use a pressure gauge to verify the test pressure.

- Use a leak detector to identify any leaks.

- Contact the manufacturer of the tube for assistance.

7. What are the different quality control procedures that can be used to ensure the accuracy and reliability of hydrostatic tubing tests?

- Use calibrated equipment.

- Follow standardized test procedures.

- Train operators on proper test procedures.

- Inspect test results for any discrepancies.

- Perform regular maintenance on test equipment.

8. What are the different reporting requirements for hydrostatic tubing tests?

- The test report should include the following information:

- The type of test performed

- The test pressure

- The test duration

- The test temperature

- The test results

- Any observations made during the test

9. What are the different industry standards that apply to hydrostatic tubing testing?

- ASTM E1110 Standard Test Method for Determination of Resistance to Hydrostatic Pressure

- ASME B31.3 Code for Pressure Piping

- ISO 1167-1 Plastics – Determination of the resistance to internal pressure – Part 1: General requirements

10. What are the different career opportunities for hydrostatic tubing testers?

- Hydrostatic tubing testers can work in a variety of industries, including the automotive, aerospace, and construction industries.

- They can also work in quality control laboratories and testing facilities.

- With experience, hydrostatic tubing testers can advance to positions such as supervisor, manager, or quality engineer.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydrostatic Tubing Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydrostatic Tubing Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hydrostatic Tubing Tester is responsible for conducting hydrostatic testing procedures to verify the integrity of pipes, tubes, and tubing systems in various industries such as automotive, aerospace, and energy. Their primary duties include:

1. Hydrostatic Testing

Perform hydrostatic testing as per established procedures and specifications to assess the pressure-bearing capacity of tubing components and systems.

- Determine appropriate test parameters such as pressure, hold time, and temperature.

- Set up and operate hydrostatic testing equipment, including pumps, gauges, and auxiliary devices.

2. Data Recording and Analysis

Record and analyze test data, including pressure readings, temperature measurements, and leak detection results.

- Evaluate data against specified criteria to determine whether tubing components meet quality standards.

- Prepare test reports and document findings, including any discrepancies or defects.

3. Maintenance and Troubleshooting

Maintain hydrostatic testing equipment and troubleshoot any issues or malfunctions.

- Conduct regular inspections and preventive maintenance to ensure equipment functionality.

- Resolve technical problems related to test setup, equipment operation, or data analysis.

4. Quality Control

Contribute to the implementation and maintenance of quality control procedures.

- Participate in the development of testing protocols and methodologies.

- Ensure compliance with industry standards and regulatory requirements.

Interview Tips

To prepare for your Hydrostatic Tubing Tester interview, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry standing. Understand the specific applications of hydrostatic testing in their area of business.

- Visit the company website and LinkedIn page.

- Review trade publications and industry news.

2. Practice Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and the role of Hydrostatic Tubing Tester. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Tell me about your experience in conducting hydrostatic testing.

- Describe a situation where you encountered a challenging test scenario and how you resolved it.

- How do you ensure the accuracy and reliability of your test results?

3. Highlight Your Technical Skills

Emphasize your proficiency in hydrostatic testing methods, equipment operation, and data analysis techniques. Mention any industry-recognized certifications or training.

- Discuss your understanding of pressure-bearing capacity, leak detection, and safety protocols.

- Share examples of successful testing projects where you provided valuable insights.

4. Demonstrate Your Problem-Solving Abilities

Employers value candidates who can identify and solve problems effectively. Share instances where you troubleshoot and resolved issues related to hydrostatic testing.

- Describe a time when you identified a problem with a test setup and implemented a solution.

- Explain how you handled discrepancies in test results and ensured accurate data interpretation.

5. Prepare Questions for the Interviewer

Ask thoughtful questions that demonstrate your interest in the role and the company. This shows that you are engaged and eager to learn more.

- Inquire about the company’s quality control standards and testing protocols.

- Ask about opportunities for professional development and advancement.

- Seek information on the team structure and reporting relationships.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hydrostatic Tubing Tester interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!