Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Automation Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

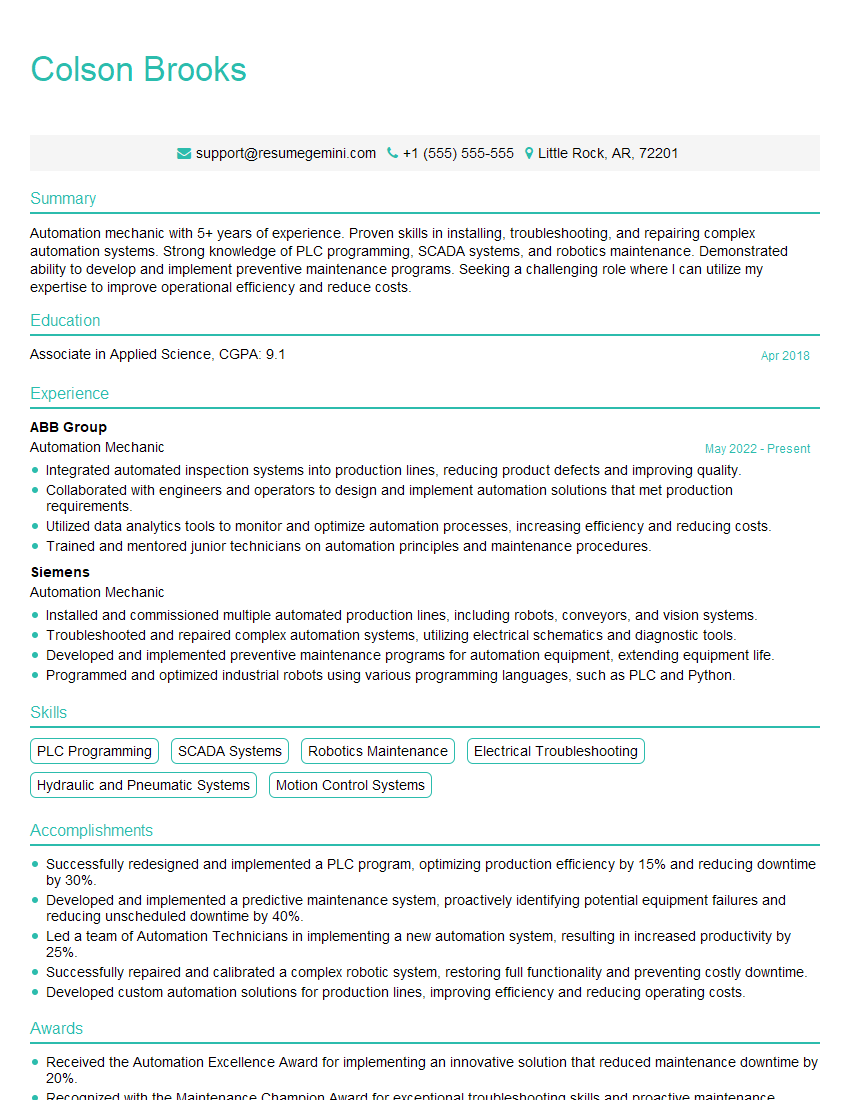

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automation Mechanic

1. What is the difference between a PLC and a DCS?

- PLCs (Programmable Logic Controllers) are compact, rugged controllers designed for industrial automation tasks, while DCSs (Distributed Control Systems) are larger, more complex systems used for controlling large-scale industrial processes.

- PLCs are typically used for controlling individual machines or processes, while DCSs are used for controlling entire plants or factories.

- PLCs are typically programmed using ladder logic, while DCSs are programmed using a variety of languages, including C, C++, and Java.

2. What are the different types of sensors used in automation?

Proximity sensors

- Inductive sensors

- Capacitive sensors

- Photoelectric sensors

Position sensors

- Encoders

- Resolvers

- Linear potentiometers

Force sensors

- Load cells

- Pressure sensors

- Torque sensors

3. What are the different types of actuators used in automation?

- Electric actuators

- Pneumatic actuators

- Hydraulic actuators

4. What are the different types of control systems used in automation?

- Open-loop control systems

- Closed-loop control systems

5. What are the different types of communication networks used in automation?

- Fieldbus networks

- Industrial Ethernet networks

- Wireless networks

6. What are the different types of software used in automation?

- PLC programming software

- DCS programming software

- SCADA software

- MES software

- ERP software

7. What are the different types of safety standards used in automation?

- IEC 61508

- ANSI/ISA-84.00.01

- NFPA 70E

8. What are the different types of maintenance tasks performed on automated systems?

- Preventive maintenance

- Predictive maintenance

- Corrective maintenance

9. What are the different types of troubleshooting techniques used on automated systems?

- Logical troubleshooting

- Electrical troubleshooting

- Mechanical troubleshooting

10. What are the different types of documentation used in automation?

- Functional specifications

- Design documents

- Operating manuals

- Maintenance manuals

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automation Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automation Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Automation Mechanics are responsible for the installation, maintenance, and repair of automated equipment and systems used in various industries. They play a crucial role in ensuring the smooth operation of these systems and maximizing their efficiency.

1. Equipment Installation and Setup

Installing and setting up new automated equipment according to specifications and ensuring proper integration with existing systems.

- Conducting site surveys and analyzing requirements.

- Assembling and installing equipment, including mechanical, electrical, and pneumatic components.

2. Troubleshooting and Repair

Diagnosing and repairing malfunctions and breakdowns in automated equipment and systems.

- Identifying the root causes of problems using diagnostic tools and techniques.

- Repairing or replacing faulty components, ensuring system functionality.

3. Maintenance and Calibration

Performing regular maintenance and calibration of automated equipment to prevent breakdowns and ensure optimal performance.

- Inspecting equipment, cleaning, lubricating, and adjusting components.

- Calibrating sensors and instruments according to established standards.

4. System Optimization and Upgrades

Evaluating the performance of automated systems and recommending improvements or upgrades to enhance efficiency and reliability.

- Analyzing system data and identifying bottlenecks or areas for optimization.

- Implementing upgrades or modifications to improve system capabilities and productivity.

Interview Tips

Preparing for an interview for an Automation Mechanic position requires a combination of technical knowledge, problem-solving skills, and a strong understanding of the industry. Here are some key tips and hacks to help you ace your interview.

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Automation Mechanic position. This shows the interviewer that you are genuinely interested in the opportunity and have taken the time to understand their operations and needs.

2. Technical Knowledge and Skills

Highlight your technical skills and knowledge related to automation mechanics, including experience with various automated systems, programming languages, and diagnostic tools. Provide specific examples of projects or tasks where you successfully applied these skills.

3. Problem-Solving and Analytical Abilities

Demonstrate your problem-solving and analytical abilities by describing how you approach and resolve technical issues with automated equipment. Use the STAR method (Situation, Task, Action, Result) to provide clear and concise examples.

4. Communication and Teamwork Skills

Automation Mechanics often work as part of a team and collaborate with other departments. Emphasize your communication skills and ability to work effectively in a team environment. Provide examples of how you have successfully communicated technical information to non-technical personnel.

- Use active listening skills to comprehend the interviewer’s questions and respond appropriately.

- Be prepared to ask thoughtful questions that show your interest and enthusiasm for the role.

- Maintain a professional and confident demeanor throughout the interview.

5. Industry Knowledge

Stay up-to-date on the latest trends and advancements in automation technology. This shows the interviewer that you are passionate about the field and eager to continue developing your skills.

6. Be Enthusiastic and Prepared

Show the interviewer that you are genuinely excited about the opportunity to work as an Automation Mechanic. Prepare for the interview by practicing your answers to common interview questions and rehearsing your technical skills.

Next Step:

Now that you’re armed with the knowledge of Automation Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Automation Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini