Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Control Equipment Electrician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Control Equipment Electrician so you can tailor your answers to impress potential employers.

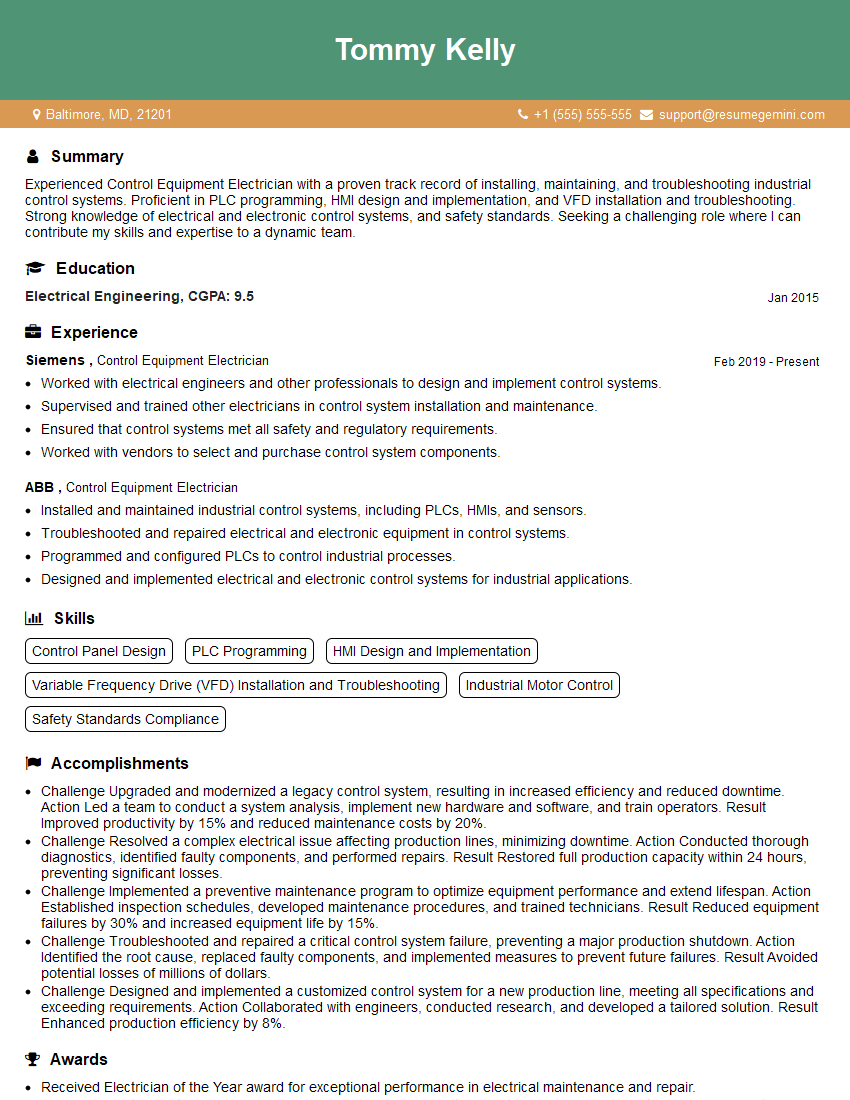

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Control Equipment Electrician

1. How do you troubleshoot a faulty control circuit?

To troubleshoot a faulty control circuit, I would follow these steps:

- Identify the symptoms of the fault, such as no power, incorrect operation, or intermittent operation.

- Inspect the circuit for any obvious defects, such as loose connections, damaged components, or burnt wires.

- Use a multimeter to check for continuity and voltage at various points in the circuit, such as the power source, switches, and control devices.

- Analyze the results of the continuity and voltage checks to identify the faulty component or connection.

- Replace or repair the faulty component or connection and retest the circuit.

2. Describe the different types of control devices and their functions.

Contactors

- Used to switch high-power loads on and off.

- Consist of a coil and a set of contacts.

- When the coil is energized, the contacts close, allowing current to flow through the load.

Relays

- Used to control low-power loads or to isolate circuits.

- Similar to contactors, but have a smaller capacity.

- Can be used to amplify a low-power signal or to provide isolation between circuits.

Timers

- Used to control the timing of events.

- Can be either mechanical or electronic.

- Mechanical timers use a clockwork mechanism to control the timing.

- Electronic timers use a digital clock to control the timing.

Sensors

- Used to detect changes in the environment, such as temperature, pressure, or motion.

- Can be either analog or digital.

- Analog sensors output a continuous signal that is proportional to the measured variable.

- Digital sensors output a discrete signal that indicates whether the measured variable is above or below a certain threshold.

3. What are the different types of ladder diagrams and their applications?

- Conventional ladder diagrams are the most common type of ladder diagram.

- They use symbols to represent contacts, coils, and other devices.

- They are easy to read and understand.

- Functional ladder diagrams are a newer type of ladder diagram that uses function blocks to represent devices.

- Function blocks are self-contained units that perform a specific function, such as adding, subtracting, or comparing.

- Functional ladder diagrams are more compact than conventional ladder diagrams and can be easier to troubleshoot.

4. What are the different types of motor control circuits?

- Across-the-line starters are the simplest type of motor control circuit.

- They consist of a contactor that connects the motor directly to the power supply.

- Wye-delta starters are used to reduce the starting current of large motors.

- They connect the motor in a wye configuration during starting and then switch to a delta configuration once the motor is up to speed.

- Soft starters are used to reduce the starting torque of large motors.

- They gradually increase the voltage applied to the motor until it reaches full speed.

5. How do you size a fuse or circuit breaker for a motor control circuit?

To size a fuse or circuit breaker for a motor control circuit, I would follow these steps:

- Determine the full-load current of the motor.

- Multiply the full-load current by a factor of 1.25 to account for starting current.

- Select a fuse or circuit breaker that has a rating equal to or greater than the calculated current.

6. How do you determine the horsepower of a motor?

- Look for the motor’s nameplate.

- The nameplate will list the motor’s horsepower.

- If the motor does not have a nameplate, you can use a formula to calculate the horsepower.

- The formula is: Horsepower = (Torque * Speed) / 5252.

- Torque is measured in foot-pounds (ft-lbs) and speed is measured in revolutions per minute (RPM).

7. How do you install a variable frequency drive (VFD)?

To install a variable frequency drive (VFD), I would follow these steps:

- Mount the VFD in a suitable location.

- Connect the input power to the VFD.

- Connect the motor to the output of the VFD.

- Configure the VFD according to the manufacturer’s instructions.

8. What are the different types of sensors used in control systems?

- Temperature sensors measure temperature.

- Pressure sensors measure pressure.

- Flow sensors measure the flow rate of a fluid.

- Level sensors measure the level of a liquid or solid.

- Position sensors measure the position of an object.

9. How do you calibrate a sensor?

To calibrate a sensor, I would follow these steps:

- Connect the sensor to a calibration instrument.

- Apply a known input to the sensor.

- Adjust the sensor’s output until it matches the known input.

10. What are the different types of control system architectures?

- Centralized control systems have a single central controller that manages all of the devices in the system.

- Decentralized control systems have multiple controllers that are distributed throughout the system.

- Distributed control systems have a network of controllers that communicate with each other and share information.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Control Equipment Electrician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Control Equipment Electrician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Control Equipment Electricians are responsible for the installation, maintenance, and repair of control equipment, including programmable logic controllers (PLCs), distributed control systems (DCSs), and other automated control devices. They ensure that the equipment functions properly and that the plant operates efficiently.

1. Installation

Control Equipment Electricians typically work in a team environment and may work on a variety of projects, from small to large. They may be responsible for the following tasks:

- Installing and testing new control equipment

- Upgrading and modifying existing control equipment

- Troubleshooting and repairing control equipment

- Calibrating and adjusting control equipment

- Maintaining records on the status of control equipment

2. Maintenance

Control Equipment Electricians must ensure that the control equipment is maintained in good working condition. This may involve the following tasks:

- Performing regular inspections and maintenance on control equipment

- Cleaning and lubricating control equipment

- Replacing worn or damaged parts

- Troubleshooting and repairing control equipment

- Calibrating and adjusting control equipment

3. Repair

Control Equipment Electricians must be able to troubleshoot and repair control equipment. This may involve the following tasks:

- Troubleshooting and repairing control equipment

- Replacing worn or damaged parts

- Adjusting settings on control equipment

- Calibrating and adjusting control equipment

- Reinstalling and testing control equipment

4. Safety

Control Equipment Electricians must follow all safety procedures and regulations when working with control equipment. This may involve the following tasks:

- Wearing proper safety gear

- Following all safety procedures and regulations

- Working in a safe and organized manner

- Reporting any unsafe conditions

- Taking appropriate action in the event of an emergency

Interview Tips

Preparing for an interview for a Control Equipment Electrician position can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will show the interviewer that you are interested in the position and that you have taken the time to learn about the company.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It can be helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Control Equipment Electrician. Be prepared to discuss your experience with installing, maintaining, and repairing control equipment, as well as any other relevant skills that you have.

4. Be yourself and be confident

The most important thing is to be yourself and be confident in your abilities. If you are prepared and you have a positive attitude, you are more likely to make a good impression on the interviewer.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Control Equipment Electrician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Control Equipment Electrician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.