Feeling lost in a sea of interview questions? Landed that dream interview for Wood Technologist but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wood Technologist interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

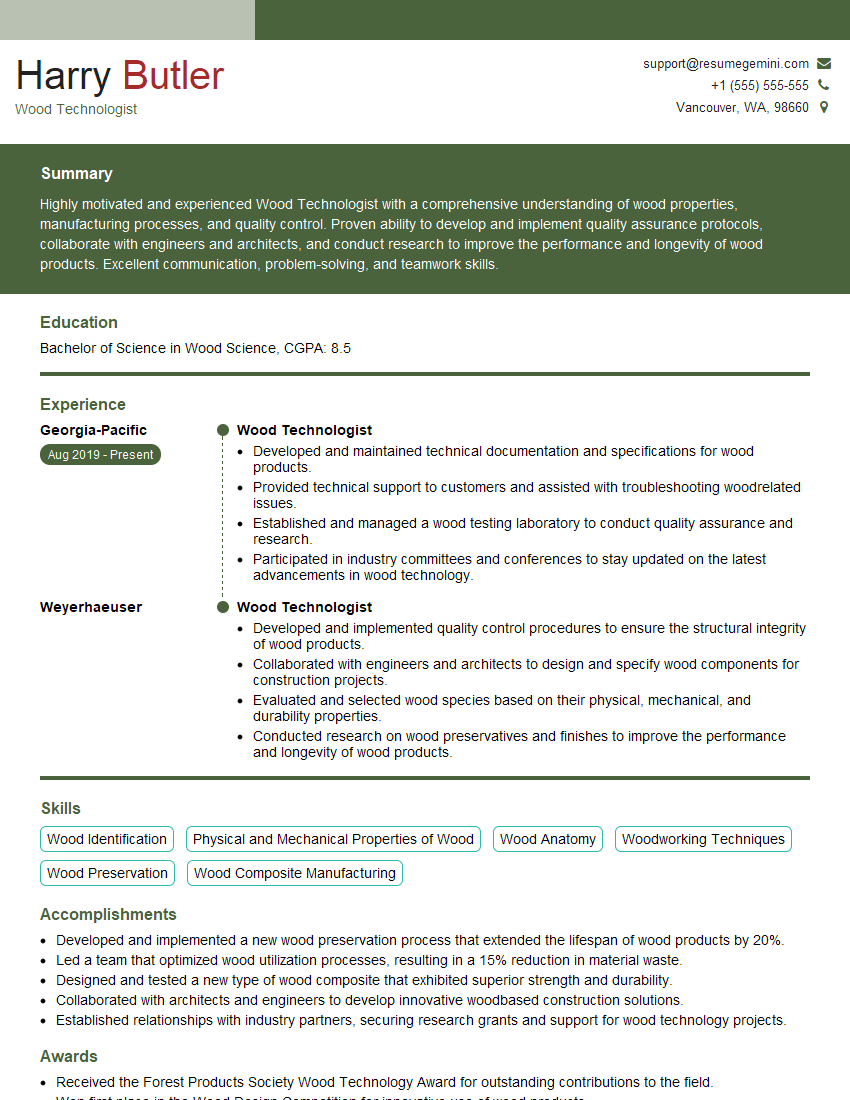

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Technologist

1. What are the key differences between hardwood and softwood species?

- Hardwood species are deciduous, meaning they lose their leaves annually, while softwood species are coniferous and retain their leaves year-round.

- Hardwood species typically have a higher density and strength than softwood species.

- Hardwood species are often used in furniture, flooring, and other high-end applications, while softwood species are commonly used in construction and papermaking.

2. Describe the process of wood seasoning and its importance.

Moisture Content

- Wood seasoning is the process of reducing the moisture content of wood to a level that is suitable for use.

- Moisture content is the amount of water present in the wood, expressed as a percentage of the dry weight of the wood.

Importance of Seasoning

- Seasoning is important because it prevents wood from warping, shrinking, and cracking.

- Seasoned wood is also more resistant to decay and insect infestation.

3. Explain the different types of wood finishes and their characteristics.

- Oil finishes penetrate the wood and provide a natural, matte finish.

- Varnish finishes create a hard, protective coating on the wood.

- Lacquer finishes are similar to varnish but dry faster and produce a glossy finish.

- Shellac finishes are made from the resin of the lac bug and provide a durable, high-gloss finish.

4. What are the key factors to consider when selecting wood for a specific application?

- Intended use: Consider the intended use of the wood, such as furniture, flooring, or construction.

- Appearance: Consider the desired appearance of the wood, such as grain pattern and color.

- Durability: Consider the durability requirements of the application, such as resistance to wear, moisture, and decay.

- Cost: Consider the cost of the wood and the budget for the project.

5. Describe the different methods used to identify wood species.

- Visual identification: Identifying wood species based on its appearance, such as grain pattern, color, and texture.

- Microscopic identification: Examining wood under a microscope to identify its cellular structure.

- Chemical identification: Using chemical tests to identify the presence of certain compounds in the wood.

- DNA analysis: Using DNA analysis to identify the genetic makeup of the wood.

6. Explain the process of wood preservation and its importance.

- Wood preservation is the process of treating wood with chemicals to protect it from decay, insects, and other environmental factors.

- Preserved wood is used in a variety of applications, such as decks, fences, and outdoor furniture.

- There are two main types of wood preservatives: waterborne and oil-borne.

7. What are the different types of wood adhesives and their applications?

- Polyvinyl acetate (PVA): A water-based adhesive that is commonly used for gluing wood to wood.

- Urea-formaldehyde (UF): A water-based adhesive that is used for gluing wood to other materials, such as metal and plastic.

- Epoxy: A two-part adhesive that is used for gluing wood to a variety of materials, including metal, plastic, and glass.

- Cyanoacrylate: A fast-acting adhesive that is used for gluing small pieces of wood.

8. Describe the different types of wood joints and their strengths and weaknesses.

- Butt joint: A simple joint that is formed by joining two pieces of wood together end-to-end.

- Lap joint: A joint that is formed by overlapping two pieces of wood.

- Miter joint: A joint that is formed by cutting two pieces of wood at a 45-degree angle and joining them together.

- Mortise and tenon joint: A joint that is formed by cutting a mortise (hole) in one piece of wood and a tenon (tongue) on the other piece of wood.

9. What are the key factors to consider when designing a wood structure?

- Load: The load that the structure will be subjected to, such as the weight of the roof, snow, and wind.

- Span: The distance that the structure will need to span.

- Wood species: The wood species that will be used for the structure.

- Joint design: The type of joints that will be used to connect the pieces of wood.

10. Describe the different types of wood-based composites and their applications.

- Plywood: A composite made from thin layers of wood veneer that are glued together.

- Oriented strand board (OSB): A composite made from strands of wood that are oriented and glued together.

- Medium density fiberboard (MDF): A composite made from wood fibers that are bonded together with resin.

- Particleboard: A composite made from wood particles that are bonded together with resin.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Technologist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Technologist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Technologists are responsible for the study of wood and wood products, including their properties, structure, and uses. They work in various industries, including forestry, construction, and manufacturing. Some of the key job responsibilities of a Wood Technologist include:

1. Conducting research on wood and wood products

Wood Technologists conduct research on the properties, structure, and uses of wood and wood products. They may also develop new products and processes for the wood industry.

- Conduct research on the properties of different types of wood, including their strength, durability, and resistance to decay.

- Develop new products and processes for the wood industry, such as new types of wood-based composites or new methods for treating wood.

2. Providing technical support to the wood industry

Wood Technologists provide technical support to the wood industry, including advising on wood selection, processing, and use. They may also develop and conduct training programs for wood industry personnel.

- Advise on the selection of wood for specific applications, such as construction, furniture, or papermaking.

- Provide technical support to wood industry personnel, such as answering questions about wood properties or processing methods.

3. Managing wood resources

Wood Technologists may also be involved in managing wood resources, including developing and implementing sustainable forestry practices. They may also work with landowners and foresters to promote the sustainable use of wood resources.

- Develop and implement sustainable forestry practices to ensure the long-term availability of wood resources.

- Work with landowners and foresters to promote the sustainable use of wood resources.

4. Teaching and research

Some Wood Technologists work in academia, where they teach and conduct research on wood and wood products. They may also develop and deliver continuing education programs for wood industry professionals.

- Teach courses on wood science and technology at colleges and universities.

- Conduct research on wood and wood products, including their properties, structure, and uses.

Interview Tips

To ace an interview for a Wood Technologist position, it is important to be well-prepared. Here are some tips to help you prepare for your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and needs. You should also review the job description carefully and identify the key skills and qualifications that the company is looking for.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills, so be prepared to talk about your education, training, and work experience. You should also highlight any relevant skills that you have, such as research skills, technical writing skills, or experience in the wood industry.

4. Ask questions of your own

Asking questions of your own at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask include “What are the biggest challenges facing the wood industry today?” and “What are the company’s goals for the future?”

5. Dress professionally and be on time

First impressions matter, so it is important to dress professionally and be on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wood Technologist interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!