Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Gear Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Gear Technician so you can tailor your answers to impress potential employers.

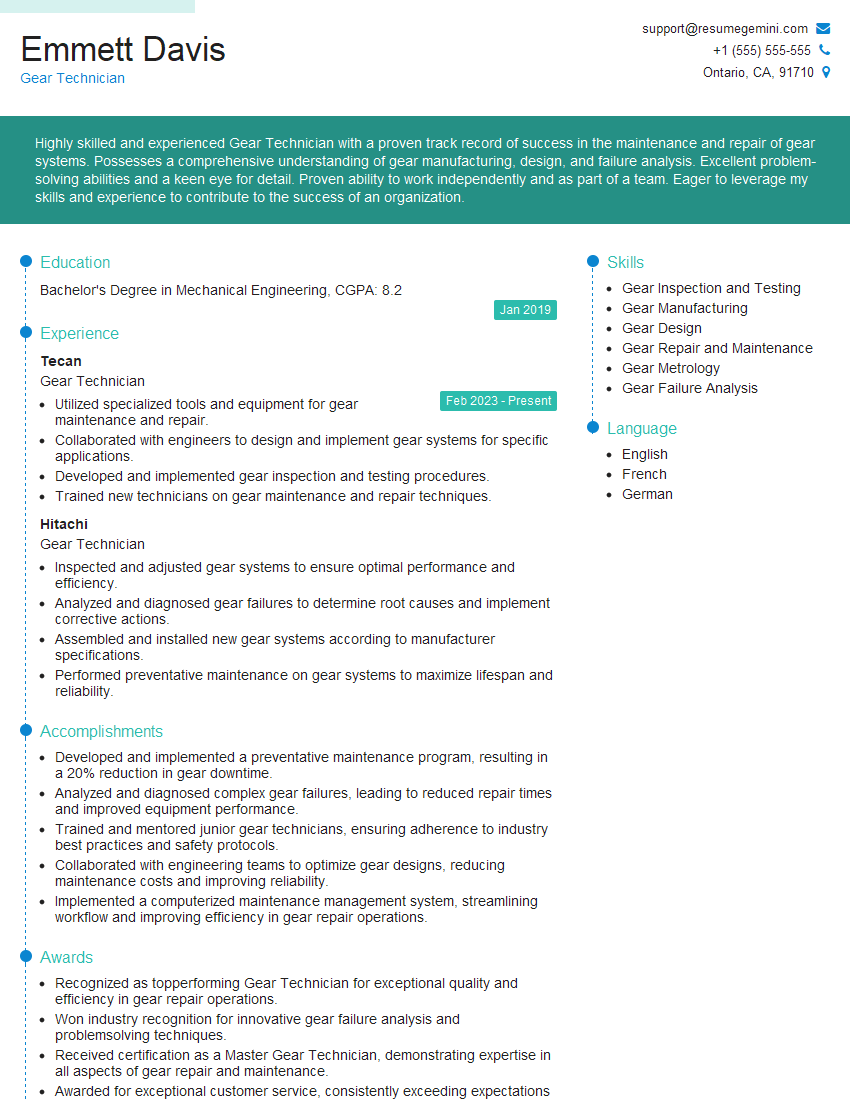

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Technician

1. Explain the types of gears and their applications.

There are various types of gears, each with its unique characteristics and applications:

- Spur gears: Used in parallel shafts for transmitting power between two shafts.

- Helical gears: Similar to spur gears but with helical teeth, allowing for smoother and quieter operation.

- Bevel gears: Used to transmit power between intersecting shafts, commonly used in gearboxes.

- Worm gears: Used to transmit power between non-intersecting shafts, providing high speed reduction.

- Rack and pinion: Used to convert rotational motion into linear motion or vice versa.

2. Describe the process of gear inspection and what equipment is used.

Visual inspection

- Examining gears for defects, wear, or damage using magnification or specialized equipment.

Dimensional inspection

- Measuring gear dimensions, such as tooth size, pitch, and profile, using calipers, micrometers, or coordinate measuring machines (CMMs).

Surface inspection

- Checking the surface finish of gears for roughness, burrs, or other anomalies using profilometers or surface roughness testers.

Non-destructive testing (NDT)

- Using techniques like magnetic particle inspection or ultrasonic testing to detect internal flaws or cracks.

3. What are the common causes of gear failure, and how can they be prevented?

Common causes of gear failure include:

- Overloading: Exceeding the rated load capacity of gears.

- Misalignment: Improper installation or wear leading to misalignment, causing excessive stress.

- Lubrication issues: Insufficient or improper lubrication, leading to increased friction and wear.

- Manufacturing defects: Faulty materials or improper machining during manufacturing.

- Wear: Gradual deterioration of gear teeth over time due to friction and contact stresses.

Prevention measures include:

- Proper load calculations and selecting gears with appropriate load ratings.

- Careful alignment during installation and regular monitoring.

- Regular lubrication using the recommended lubricants and intervals.

- Quality control during manufacturing to minimize defects.

- Regular inspections and maintenance to detect wear or potential issues early.

4. How do you calculate the gear ratio and center distance between two gears?

Gear ratio:

- Ratio between the number of teeth on the driving gear (Nd) and the number of teeth on the driven gear (Nr):

- Gear ratio = Nd / Nr

Center distance:

- Distance between the centers of two gears in mesh:

- Center distance = (Nd + Nr) / 2 * Pd

- where Pd is the diametral pitch of the gears.

5. What is the difference between involute and cycloidal gear teeth, and which type is more commonly used?

Involute gear teeth:

- Commonly used in spur, helical, and bevel gears.

- Gradually engaging shape allows for smooth transmission of power.

Cycloidal gear teeth:

- Used in some specialized applications.

- Interlocking shape provides high load-carrying capacity.

Involute gear teeth are more commonly used due to their smoother operation and wider range of applications.

6. How do you determine the material and heat treatment requirements for a gear based on its application?

Material selection and heat treatment depend on the application’s requirements, such as:

- Load: Higher loads require stronger materials.

- Speed: Higher speeds increase the risk of wear and require materials with good wear resistance.

- Temperature: Gears operating in high temperatures may require materials with better thermal stability.

- Corrosion resistance: Gears exposed to corrosive environments need materials with high corrosion resistance.

Common gear materials include steel, stainless steel, aluminum alloys, and plastics.

7. How do you assess the noise levels of a gear and what are the factors that affect it?

Gear noise can be assessed using decibel meters or specialized noise analyzers.

Factors affecting gear noise include:

- Gear design: Pitch, profile, and surface finish.

- Materials: Material properties and hardness.

- Lubrication: Type of lubricant and lubrication level.

- Operating conditions: Load, speed, and temperature.

8. What are the environmental factors that can affect the performance of gears and how can they be mitigated?

Environmental factors that can affect gears include:

- Temperature: Extreme temperatures can affect lubricant viscosity, gear materials, and clearance.

- Humidity: High humidity can lead to corrosion and surface degradation.

- Dust and dirt: Contaminants can increase friction and wear.

Mitigation measures include:

- Using temperature-resistant lubricants and materials.

- Providing proper ventilation and sealing against moisture.

- Filtering the air to reduce contaminants.

9. How do you maintain and troubleshoot common gear problems, such as excessive wear, noise, or vibration?

Excessive wear:

- Check lubrication, alignment, and load conditions.

- Inspect gears for damage or excessive wear.

Noise:

- Assess noise levels and identify the source.

- Check gear alignment, tooth profile, and lubrication.

Vibration:

- Measure vibration and locate the source.

- Check for misalignment, imbalance, or gear damage.

10. What are the latest advancements in gear technology and how do they impact the industry?

Recent advancements in gear technology include:

- Advanced materials: New materials with improved strength, wear resistance, and thermal stability.

- Additive manufacturing: 3D printing techniques to produce complex gear designs.

- Precision machining: Advanced machining techniques for high-precision gear manufacturing.

- Predictive maintenance: Sensors and data analysis to monitor gear health and predict failures.

These advancements improve gear performance, efficiency, and reliability, impacting various industries such as automotive, aerospace, and manufacturing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gear Technicians play a crucial role in ensuring the safe and efficient operation of gears in various industries. Their key responsibilities include:

1. Gear Inspection and Troubleshooting

Inspecting gears for wear, damage, or misalignment using specialized equipment and techniques.

- Conducting root cause analysis to identify the source of gear problems.

- Developing and implementing corrective actions to resolve issues.

2. Gear Maintenance and Repair

Performing preventive maintenance tasks to extend gear life and prevent breakdowns.

- Lubricating gears according to manufacturer’s specifications.

- Adjusting gear clearances and alignments.

3. Gear Design and Analysis

Supporting engineers in designing and analyzing gears for specific applications.

- Conducting stress and fatigue analysis to ensure gear reliability.

- Developing gear specifications and drawings.

4. Quality Control and Documentation

Monitoring gear quality and ensuring compliance with industry standards.

- Maintaining detailed records of gear inspections, repairs, and modifications.

- Preparing technical reports and presentations.

Interview Tips and Preparation

To excel in a Gear Technician interview, meticulous preparation is essential. Here are a few tips and interview hacks to help you:

1. Research the Company and Position

- Thoroughly review the company’s website and social media profiles to gain insights into their culture, values, and gear-related expertise.

- Study the job description meticulously to understand the specific responsibilities, requirements, and desired qualifications.

2. Highlight Relevant Experience and Skills

- Showcase your practical experience in gear inspection, maintenance, or design.

- Quantify your accomplishments using specific metrics and examples.

- Emphasize your proficiency in relevant software and technologies used in the gear industry.

3. Prepare Industry-Specific Questions

- Research the latest gear technologies, advancements, and industry trends.

- Prepare questions that demonstrate your understanding of the field and your eagerness to learn.

- For instance, you could ask about the company’s approach to predictive maintenance or their experience with a particular gear material.

4. Dress Professionally and Practice Confidence

- Make a positive impression by dressing appropriately for the interview. Typically, business casual attire is suitable.

- Practice answering common interview questions in front of a mirror or with a friend to build confidence and improve your delivery.

- Maintain a positive attitude and convey your enthusiasm for the role throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gear Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!