Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Instrumentation Fitter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Instrumentation Fitter so you can tailor your answers to impress potential employers.

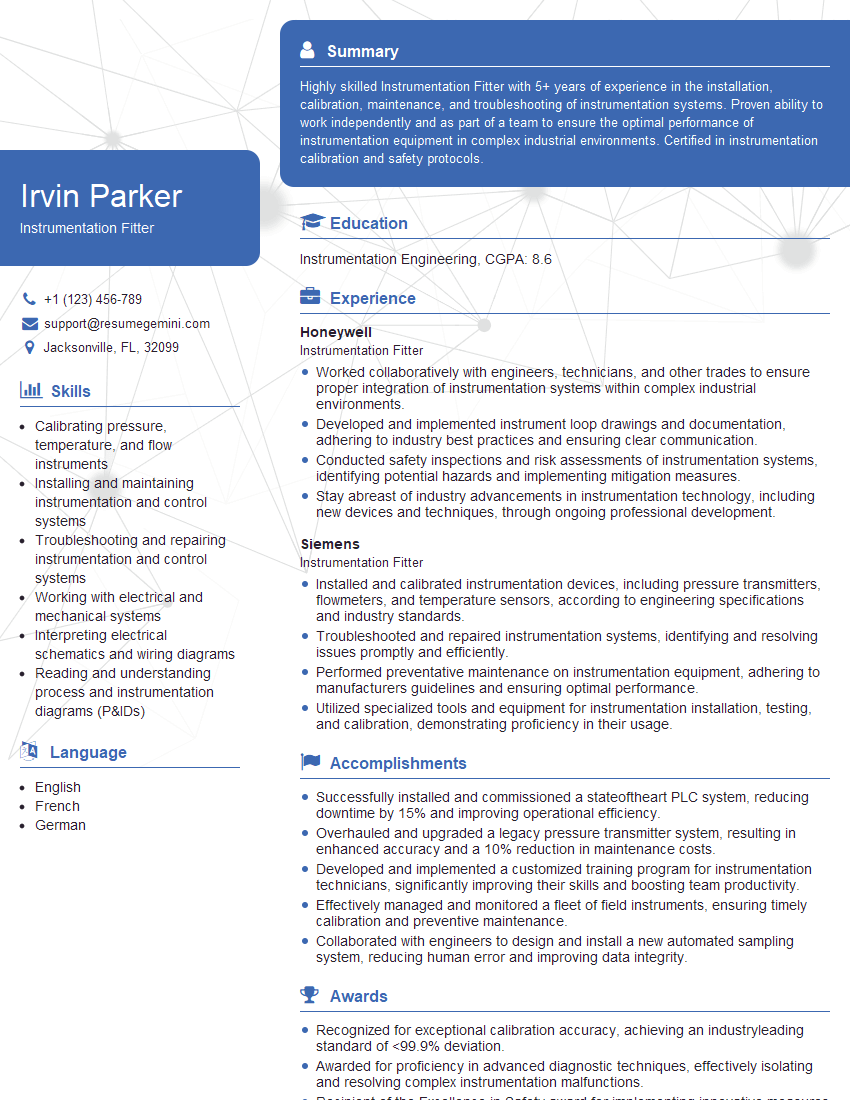

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrumentation Fitter

1. Explain the purpose and working principle of a pressure transmitter?

A pressure transmitter is a device that converts a pressure signal into an electrical signal. It is used to measure the pressure of a fluid, such as air, gas, or liquid.

- The pressure transmitter consists of a diaphragm that is connected to a strain gauge. When pressure is applied to the diaphragm, it deflects, which causes the strain gauge to change resistance.

- The change in resistance is then converted to an electrical signal, which is proportional to the pressure applied to the diaphragm.

2. What are the different types of flowmeters, and how do they work?

Turbine flowmeter

- A turbine flowmeter consists of a turbine that is placed in the path of the flowing fluid. As the fluid flows through the turbine, it causes the turbine to rotate.

- The speed of rotation of the turbine is proportional to the flow rate of the fluid.

Ultrasonic flowmeter

- An ultrasonic flowmeter uses ultrasonic waves to measure the flow rate of a fluid. The ultrasonic waves are transmitted through the fluid, and the time it takes for the waves to travel through the fluid is measured.

- The flow rate of the fluid is then calculated based on the time it takes for the waves to travel through the fluid.

3. What are the different types of valves, and how are they used in instrumentation?

- Gate valve: A gate valve is used to isolate a section of piping. It consists of a gate that slides up or down to block or allow the flow of fluid.

- Globe valve: A globe valve is used to control the flow of fluid. It consists of a disk that is attached to a stem. The stem is rotated to open or close the valve.

- Ball valve: A ball valve is used to isolate a section of piping or to control the flow of fluid. It consists of a ball that is rotated to block or allow the flow of fluid.

4. What are the different types of level sensors, and how do they work?

Float level sensor

- A float level sensor consists of a float that is connected to a switch. The float floats on the surface of the liquid, and when the liquid level rises, the float rises and activates the switch.

- The switch then sends a signal to the controller, which indicates that the liquid level has reached a certain level.

Ultrasonic level sensor

- An ultrasonic level sensor uses ultrasonic waves to measure the level of a liquid. The ultrasonic waves are transmitted through the liquid, and the time it takes for the waves to travel through the liquid is measured.

- The level of the liquid is then calculated based on the time it takes for the waves to travel through the liquid.

5. What are the different types of temperature sensors, and how do they work?

Thermocouple

- A thermocouple consists of two dissimilar metals that are joined together at one end. When the junction of the two metals is heated, a voltage is generated.

- The voltage is proportional to the temperature of the junction.

Resistance temperature detector (RTD)

- An RTD consists of a coil of wire that is made of a material with a known temperature coefficient of resistance. When the temperature of the RTD changes, the resistance of the coil changes.

- The change in resistance is then converted to a voltage, which is proportional to the temperature of the RTD.

6. What are the different types of control valves, and how do they work?

Pneumatic control valve

- A pneumatic control valve uses compressed air to operate. It consists of a diaphragm that is connected to a stem. The stem is connected to the valve plug, which controls the flow of fluid.

Electric control valve

- An electric control valve uses an electric motor to operate. It consists of a motor that is connected to a stem. The stem is connected to the valve plug, which controls the flow of fluid.

7. What are the different types of process control systems, and how do they work?

Open-loop control system

- An open-loop control system does not use feedback to control the process.

- Instead, the output of the system is determined by the input signal.

Closed-loop control system

- A closed-loop control system uses feedback to control the process.

- The feedback signal is used to compare the actual output of the system to the desired output.

- The error signal is then used to adjust the input signal to the system.

8. What are the different types of programmable logic controllers (PLCs), and how do they work?

Small PLCs

- Small PLCs are typically used in small applications, such as controlling a single machine or a small group of machines.

- Small PLCs typically have a limited number of inputs and outputs, and they are programmed using a simple ladder logic language.

Large PLCs

- Large PLCs are typically used in large applications, such as controlling a complex process or a large group of machines.

- Large PLCs typically have a large number of inputs and outputs, and they are programmed using a more complex programming language, such as IEC 61131-3.

9. What are the different types of distributed control systems (DCSs), and how do they work?

Centralized DCSs

- Centralized DCSs have a single central controller that controls all of the devices in the system.

- The central controller typically communicates with the devices in the system using a fieldbus.

Decentralized DCSs

- Decentralized DCSs have multiple controllers that are distributed throughout the system.

- Each controller controls a specific part of the system.

- The controllers communicate with each other using a network.

10. What are the different types of safety instrumented systems (SISs), and how do they work?

Basic SISs

- Basic SISs are typically used in small applications, such as protecting a single machine or a small group of machines.

- Basic SISs typically have a limited number of inputs and outputs, and they are programmed using a simple programming language, such as ladder logic.

Complex SISs

- Complex SISs are typically used in large applications, such as protecting a complex process or a large group of machines.

- Complex SISs typically have a large number of inputs and outputs, and they are programmed using a more complex programming language, such as IEC 61508.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrumentation Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrumentation Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fitting, installing, maintaining, repairing, and testing instrumentation equipment, such as sensors, transmitters, controllers, and valves. Working with electrical and mechanical drawings and specifications to determine the location and installation requirements of equipment. Using hand and power tools to assemble, install, and repair instrumentation equipment. Testing and calibrating instrumentation equipment to ensure it meets performance specifications. Troubleshooting and repairing instrumentation equipment, such as sensors, transmitters, controllers, and valves. Maintaining and repairing pneumatic and hydraulic systems. Working in a safe and clean environment. Following all safety procedures.Interview Tips

Research the company and the position. This will help you understand the company’s culture, values, and what they are looking for in a candidate. Practice your answers to common interview questions. This will help you feel more confident and prepared during the interview. Dress professionally and arrive on time for your interview. First impressions matter, so make sure you put your best foot forward. Be enthusiastic and positive during the interview. The interviewer wants to see that you are excited about the position and the company. Ask questions at the end of the interview. This shows that you are interested in the position and that you are engaged in the conversation. Follow up with the interviewer after the interview. This is a great way to thank the interviewer for their time and to reiterate your interest in the position. Here are some additional tips that can help you ace your interview: Be prepared to talk about your experience and skills. The interviewer will want to know what you have done in the past and what you can bring to the company. Be honest and authentic. The interviewer will be able to tell if you are being genuine, so be yourself and let your personality shine through. Be confident. The interviewer will be more likely to be impressed by you if you believe in yourself. Be respectful. The interviewer is taking the time to interview you, so be respectful of their time and their questions. Be enthusiastic. The interviewer will be more likely to hire someone who is excited about the position and the company. By following these tips, you can increase your chances of acing your interview and landing the job you want.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Instrumentation Fitter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!