Are you gearing up for an interview for a Airplane Rigger position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Airplane Rigger and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

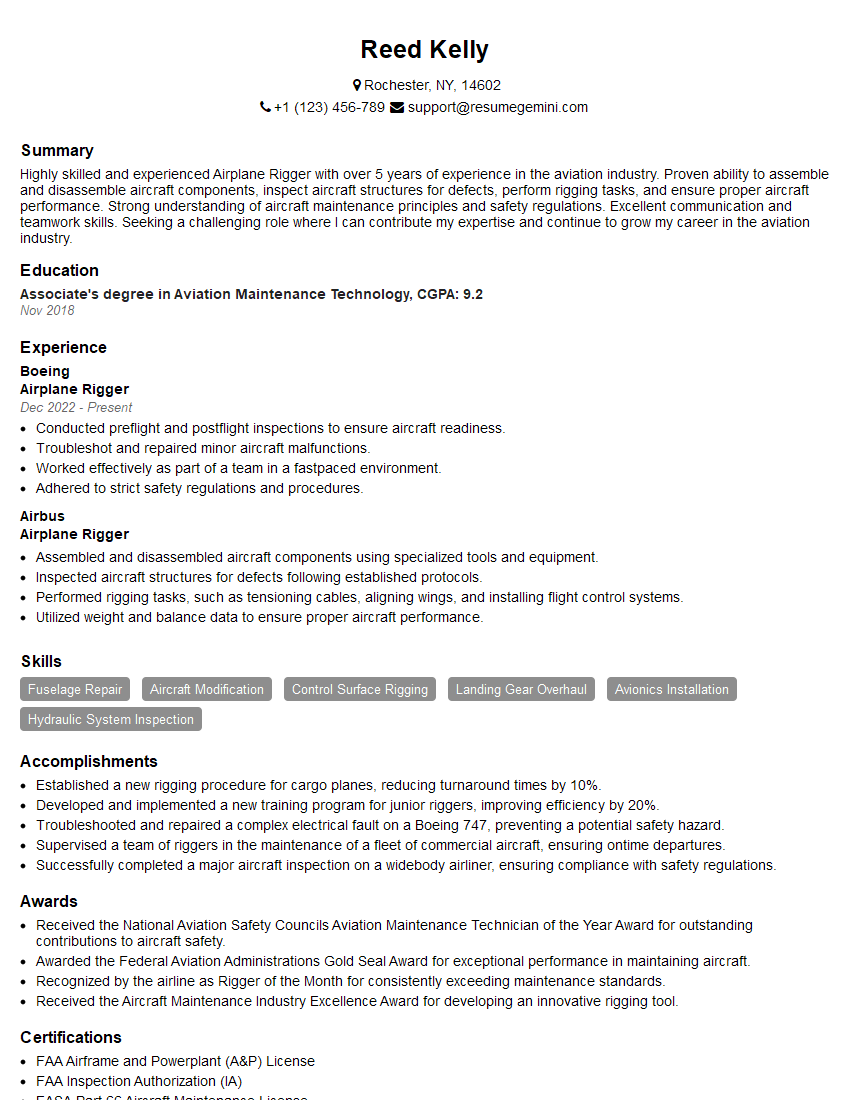

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Airplane Rigger

1. Explain the process of inspecting and maintaining aircraft control systems?

- Review maintenance manuals and technical orders to determine specific inspection and maintenance procedures.

- Visually inspect control surfaces, linkages, cables, pulleys, and other components for signs of wear, corrosion, or damage.

- Perform functional tests to verify the proper operation of control systems, including control stick and rudder movements.

- Make adjustments or repairs as necessary to ensure the aircraft meets safety and performance standards.

- Document all inspections and maintenance activities in the aircraft’s logbook.

2. Describe the different types of aircraft rigging and their purposes?

- Flying controls rigging: Ensures accurate and responsive control of the aircraft’s flight surfaces, such as ailerons, elevators, and rudders.

- Landing gear rigging: Adjusts the alignment and operation of landing gear components, such as wheels, brakes, and struts, for safe and effective landings.

- Engine rigging: Aligns and synchronizes engine components, such as propellers and carburetors, for optimal performance and efficiency.

- Fuel system rigging: Ensures proper fuel flow and distribution throughout the aircraft’s fuel system.

- Electrical system rigging: Connects and insulates electrical components, such as wiring, switches, and batteries, for reliable electrical power supply.

3. How do you ensure the accuracy and precision of your rigging work?

- Thoroughly review technical data and consult with engineers and inspectors to understand the required specifications.

- Use specialized tools and equipment, such as protractors, tension meters, and alignment gauges, to measure and adjust components precisely.

- Follow established procedures and industry standards to ensure consistent and accurate rigging.

- Double-check and verify all measurements and adjustments before completing the work.

- Obtain sign-off from authorized personnel to certify the accuracy and compliance of the rigging work.

4. What are the common troubleshooting techniques you use for aircraft rigging issues?

- Visual inspection: Examine components for signs of damage, wear, or misalignment.

- Functional testing: Operate control surfaces or systems to identify any anomalies or malfunctions.

- Troubleshooting charts: Consult manufacturer’s documentation and troubleshooting guides to narrow down potential causes.

- Symptom analysis: Analyze the observed symptoms to determine the underlying issue.

- Repair or replacement: Identify and repair or replace faulty components to restore functionality.

5. How do you stay up-to-date with advancements in aircraft rigging techniques and industry regulations?

- Attend industry conferences, seminars, and training programs.

- Read technical publications, manuals, and articles from reputable sources.

- Engage in online forums and discussions with fellow riggers and industry experts.

- Review and comply with updates to regulatory standards, such as FAA regulations and manufacturer’s bulletins.

- Seek guidance from certified aircraft inspectors and engineers to stay informed about best practices.

6. Describe a challenging aircraft rigging project you successfully completed?

- Explain the complexity of the project and the specific challenges encountered.

- Describe the steps taken to troubleshoot and resolve the issues.

- Highlight the techniques and tools used to achieve the desired outcome.

- Emphasize the importance of accuracy, precision, and attention to detail.

- Mention the positive impact your work had on the aircraft’s performance or safety.

7. How do you ensure the safety and quality of your rigging work?

- Adhere to established safety procedures and guidelines.

- Use appropriate personal protective equipment (PPE) and tools.

- Thoroughly inspect all components before and after rigging.

- Follow manufacturer’s instructions and industry standards.

- Obtain sign-off from authorized personnel to certify the safety and quality of the work.

8. How do you prioritize multiple rigging tasks and manage your time effectively?

- Prioritize tasks based on urgency and safety: Address critical rigging issues first.

- Plan and schedule work: Establish a clear work plan and allocate time accordingly.

- Communicate effectively: Inform supervisors and colleagues about task status and any potential delays.

- Delegate tasks when possible: Assign tasks to qualified colleagues to improve efficiency.

- Monitor progress and adjust as needed: Regularly review progress and make adjustments to the schedule if necessary.

9. How do you handle working at heights and in confined spaces?

- Comply with safety regulations: Adhere to established fall protection and confined space entry procedures.

- Use appropriate PPE and equipment: Utilize fall harnesses, scaffolding, and other safety gear.

- Conduct risk assessments: Identify potential hazards and implement appropriate mitigation measures.

- Maintain clear communication: Inform colleagues and supervisors of work location and status.

- Be aware of physical limitations: Recognize personal limitations and seek assistance when necessary.

10. How do you stay motivated and maintain a positive attitude in a demanding work environment?

- Recognize the importance of my role: Understand the critical impact of rigging on aircraft safety and performance.

- Set realistic goals: Break down large tasks into smaller, achievable milestones.

- Maintain a growth mindset: View challenges as opportunities for learning and improvement.

- Collaborate with colleagues: Share knowledge and support each other to create a positive work environment.

- Celebrate successes: Acknowledge and celebrate both individual and team accomplishments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Airplane Rigger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Airplane Rigger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Airplane Rigger is a highly skilled professional responsible for the assembly, maintenance, and repair of aircraft and their components. They work closely with engineers, mechanics, and other technicians to ensure the safety and performance of aircraft.

1. Assembly and Installation

Airplane Riggers assemble and install aircraft components, including wings, fuselage, landing gear, and control systems. They use specialized tools and equipment to ensure that all parts are correctly aligned and secured.

- Assemble aircraft structures according to blueprints and specifications.

- Install and align aircraft components, such as wings, engines, and landing gear.

2. Maintenance and Repair

Airplane Riggers perform routine maintenance and repairs on aircraft to ensure their continued airworthiness. They inspect and adjust control systems, hydraulics, and other components to keep them functioning properly.

- Inspect and repair aircraft structures, control systems, and landing gear.

- Replace or repair damaged or worn components.

3. Troubleshooting

Airplane Riggers are skilled at troubleshooting and resolving issues with aircraft systems. They use their knowledge of aircraft mechanics to identify and correct problems in a timely manner.

- Diagnose and resolve mechanical problems with aircraft systems.

- Troubleshoot and repair electrical and hydraulic systems.

4. Quality Control

Airplane Riggers perform quality control checks to ensure that all work meets the required standards. They inspect completed assemblies for accuracy and compliance with specifications.

- Inspect and verify the accuracy of aircraft assemblies.

- Ensure that all work meets the required quality standards.

Interview Tips

Preparing thoroughly for an Airplane Rigger interview is essential to showcasing your skills and impressing potential employers. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, research the company you are applying to and the aviation industry as a whole. This will help you understand the company’s culture, values, and the challenges and opportunities in the field.

- Visit the company website to learn about their products, services, and recent developments.

- Read industry publications and news articles to stay up-to-date on the latest trends and technologies.

2. Practice Your Skills

Airplane Riggers need to possess strong technical skills. Before the interview, review your knowledge of aircraft mechanics, assembly, and repair techniques. You should also practice using specialized tools and equipment.

- Go over the fundamentals of aircraft structures, control systems, and hydraulics.

- Practice troubleshooting and identifying common problems in aircraft systems.

3. Prepare Relevant Examples

In your interview, you will be asked about your experience and skills. Be prepared to give specific examples of your work in aircraft assembly, maintenance, and troubleshooting.

- Describe a time when you successfully assembled or repaired an aircraft component.

- Give an example of how you diagnosed and resolved an issue with an aircraft system.

4. Show Your Passion and Enthusiasm

Employers are looking for candidates who are passionate about aviation and eager to work on aircraft. Let your enthusiasm for the field shine through in your interview by expressing your interest in the industry and discussing your knowledge of aircraft technology.

- Share your experience with aviation, whether through personal projects, hobbies, or extracurricular activities.

- Explain why you are interested in working as an Airplane Rigger and why you are excited about the opportunity to contribute to the aviation industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Airplane Rigger interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!