Feeling lost in a sea of interview questions? Landed that dream interview for FAA Certified Powerplant Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common FAA Certified Powerplant Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

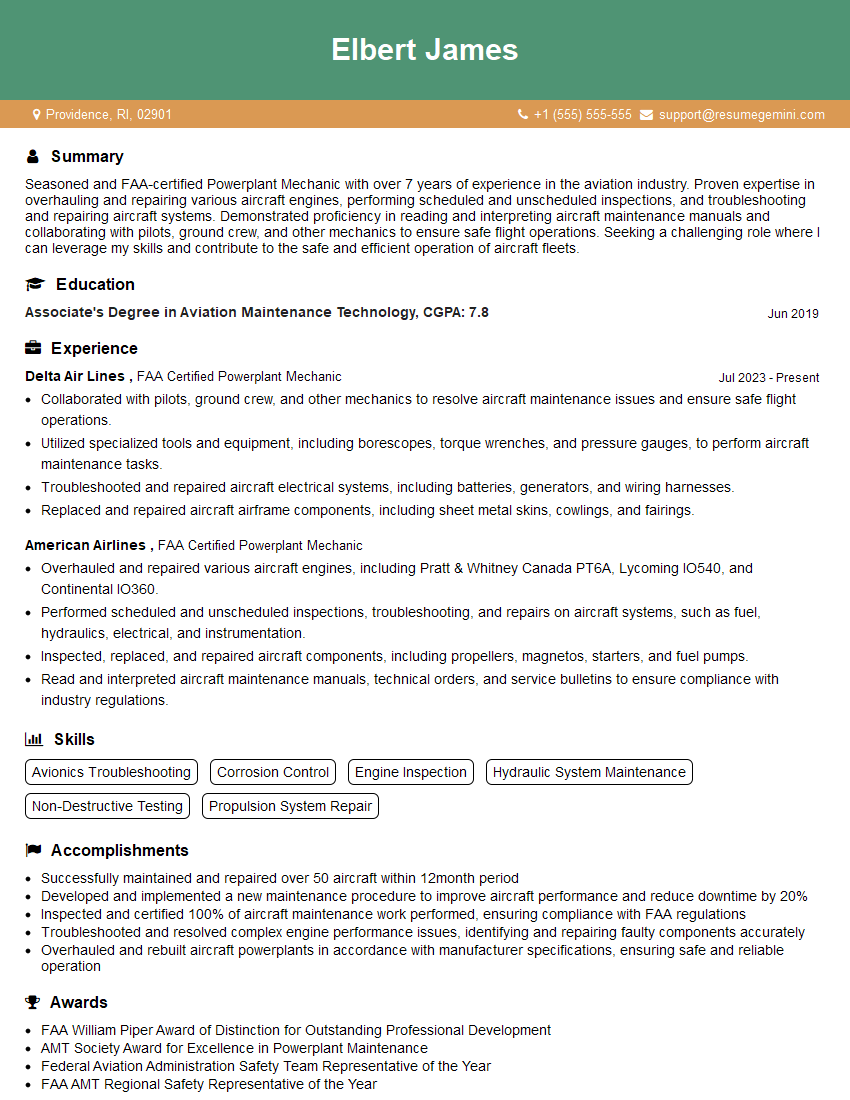

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For FAA Certified Powerplant Mechanic

1. Describe the steps involved in troubleshooting a faulty ignition system?

- Conduct a visual inspection to check for damaged wires, connectors, or other signs of physical damage.

- Test the continuity of the ignition system components, such as the ignition switch, distributor, and spark plugs.

- Use a multimeter to measure the voltage and resistance at various points in the ignition system.

- Perform a spark test to check if the system is producing a spark.

- Replace any faulty components or repair any damaged wires or connectors.

2. Explain the procedure for performing a compression test on a reciprocating engine?

Step 1: Safety Precautions

- Ensure the engine is cool and stationary.

- Wear appropriate safety gear, including gloves and eye protection.

Step 2: Equipment Preparation

- Install a compression tester in place of the spark plug.

- Charge the battery or connect to a power source.

Step 3: Test Execution

- Disable the ignition system to prevent the engine from starting.

- Crank the engine for several revolutions.

- Record the maximum reading on the compression tester.

Step 4: Interpretation

- Compare the results to the engine manufacturer’s specifications.

- Low compression readings may indicate worn piston rings, valves, or a head gasket leak.

3. How would you inspect and repair an oil leak on a gas turbine engine?

- Identify the source of the leak by visual inspection and soapy water solution.

- Clean the area around the leak thoroughly.

- Replace any damaged seals or gaskets.

- Apply a high-temperature sealant to the repaired area.

- Monitor the repaired area after testing the engine to ensure the leak has been resolved.

4. Describe the process of balancing a propeller?

- Install the propeller on a balancing stand and rotate it at a low speed.

- Identify the heavy point on the propeller by observing the amount of vibration.

- Remove a small amount of material from the heavy point on the propeller.

- Repeat steps 1-3 until the propeller is balanced and produces minimal vibration.

5. How would you calculate the torque required to tighten a bolt to a specified torque value?

- Determine the diameter of the bolt using a vernier caliper or bolt gauge.

- Refer to a torque chart to find the recommended torque value for the bolt size and grade.

- Multiply the torque value by the coefficient of friction for the material combination of the bolt and nut.

- The result is the torque required to tighten the bolt to the specified torque value.

6. What are the key safety considerations when working on aircraft electrical systems?

- Always disconnect the battery or external power supply before working on any electrical components.

- Use insulated tools and wear non-conductive gloves and clothing.

- Ensure the work area is well-lit and free from clutter.

- Tag out or lock out electrical panels and circuit breakers.

- Follow all applicable safety protocols and procedures.

7. Explain the operation of a constant-speed propeller governor?

- The governor senses changes in propeller speed.

- It sends a signal to the propeller control unit to adjust the blade angle.

- This maintains the desired propeller speed, regardless of changes in engine power or aircraft speed.

8. Describe the procedures for performing a borescope inspection on an aircraft engine?

- Select the appropriate borescope and attachment.

- Insert the borescope into the engine through an access port.

- Inspect the internal components for any damage, wear, or corrosion.

- Capture images or videos of the inspection.

- Prepare a report detailing the findings of the inspection.

9. What are the different types of nondestructive testing methods used in aviation maintenance?

- Visual inspection

- Eddy current testing

- Ultrasonic testing

- Radiography

- Magnetic particle inspection

- Penetrant testing

10. How would you troubleshoot a hydraulic system that is experiencing low pressure?

- Check the hydraulic fluid level and condition.

- Inspect the hydraulic pump for any leaks or damage.

- Inspect the hydraulic lines and fittings for any leaks or blockages.

- Test the hydraulic pressure relief valve.

- Check the operation of the hydraulic actuators.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for FAA Certified Powerplant Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the FAA Certified Powerplant Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an FAA Certified Powerplant Mechanic, you will be responsible for the maintenance, repair, and overhaul of aircraft engines and related systems. Your duties will include:

1. Inspection and Troubleshooting

Inspecting aircraft engines, components, and systems for signs of wear, damage, or malfunction.

- Troubleshooting and diagnosing mechanical problems with aircraft engines and related systems.

- Using specialized tools and equipment to perform diagnostic tests and identify the source of problems.

2. Repair and Overhaul

Repairing and overhauling aircraft engines and related systems, including:

- Replacing worn or damaged parts.

- Rebuilding and reassembling engines and components.

- Performing precision adjustments and calibrations.

3. Maintenance and Documentation

Performing scheduled maintenance and inspections on aircraft engines and related systems.

- Lubricating and servicing engines and components.

- Replacing filters and fluids.

- Maintaining accurate records of all maintenance and repair work performed.

4. Safety and Compliance

Ensuring that all work performed meets FAA regulations and safety standards.

- Following established maintenance manuals and procedures.

- Using proper tools and equipment for the job.

- Reporting any potential safety hazards or concerns to supervisors.

Interview Tips

To prepare for your interview for an FAA Certified Powerplant Mechanic position, consider the following tips:

1. Research the Company and Position

Research the company you are applying to and the specific requirements of the position. This will help you understand their business and what they are looking for in a candidate.

- Visit the company website to learn about their history, mission, and values.

- Read the job description carefully and identify the key skills and experiences required.

2. Practice Answering Common Interview Questions

Practice answering common interview questions related to your skills, experience, and qualifications. This will help you feel more confident and prepared during the actual interview.

- Prepare for questions about your experience with aircraft engine maintenance and repair.

- Practice describing your troubleshooting and problem-solving abilities.

- Be ready to discuss your knowledge of FAA regulations and safety standards.

3. Highlight Your Relevant Skills and Experience

Emphasize your relevant skills and experience during the interview. Be specific and provide examples of your work.

- Highlight your experience with different types of aircraft engines and systems.

- Provide examples of complex repairs or overhauls you have successfully completed.

- Quantify your accomplishments whenever possible, using numbers and metrics.

4. Be Professional and Enthusiastic

Dress professionally and arrive on time for your interview. Be polite and respectful to everyone you meet.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be enthusiastic about the position and demonstrate your passion for aircraft maintenance.

- Thank the interviewer for their time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the FAA Certified Powerplant Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!