Are you gearing up for an interview for a Experimental Aircraft Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Experimental Aircraft Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

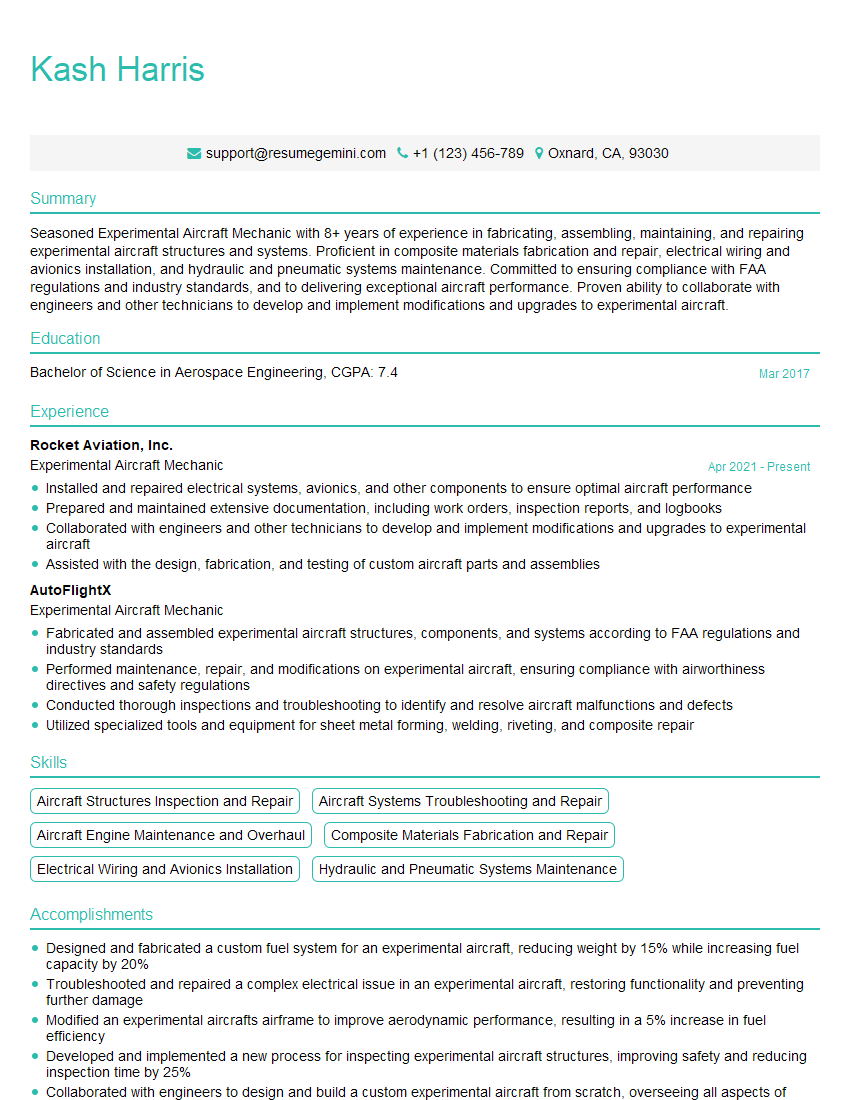

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Experimental Aircraft Mechanic

1. Explain the process of installing an aircraft electrical system?

- Wiring the electrical components, such as lights, radios, and navigation systems, according to the aircraft’s electrical schematics.

- Inspecting and testing the electrical system to ensure proper functionality and compliance with safety regulations.

- Troubleshooting and repairing any electrical malfunctions or defects.

- Maintaining and updating the electrical system to meet evolving requirements and technological advancements.

2. What are the different types of composite materials used in aircraft construction, and what are their advantages and disadvantages?

Types of Composite Materials:

- Carbon Fiber Reinforced Polymer (CFRP): High strength-to-weight ratio, stiffness, and durability.

- Fiberglass Reinforced Polymer (FRP): Good strength, flexibility, and corrosion resistance.

- Kevlar Reinforced Polymer (KRP): High strength-to-weight ratio, impact resistance, and thermal insulation.

- Thermoplastic Composites (TPCs): High toughness, formability, and recyclability.

Advantages:

- Lightweight: Reduced aircraft weight for increased fuel efficiency and performance.

- Durability: Resistance to corrosion, fatigue, and impact damage.

- Strength: High strength-to-weight ratio for improved structural integrity.

- Formability: Can be molded into complex shapes for aerodynamic efficiency.

Disadvantages:

- Cost: More expensive than traditional materials like aluminum.

- Complexity: Requires specialized manufacturing and repair techniques.

- Environmental concerns: Disposal and recycling can be challenging.

3. How do you ensure the accuracy of aircraft measurements during maintenance and repair?

- Using calibrated measuring tools and instruments, such as micrometers, calipers, and rulers.

- Following the manufacturer’s specifications and maintenance manuals.

- Double-checking measurements and calculations.

- Employing precision measuring techniques, such as laser alignment and digital scanning.

- Maintaining a clean and well-lit work area to minimize errors.

4. Describe your experience in troubleshooting and repairing aircraft hydraulic systems.

Troubleshooting:

- Identifying the symptoms of a hydraulic system malfunction.

- Performing visual inspections and leak tests.

- Using diagnostic tools, such as pressure gauges and flow meters.

- Analyzing system data and maintenance records.

Repairing:

- Replacing or repairing faulty components, such as pumps, valves, and lines.

- Flushing and cleaning the system to remove contaminants.

- Testing and adjusting the system to ensure proper operation.

- Documenting maintenance actions and repairs performed.

5. What are the safety precautions you take when working on aircraft fuel systems?

- Wearing appropriate personal protective equipment (PPE), including gloves, goggles, and fire-resistant clothing.

- Grounding aircraft to prevent static electricity buildup.

- Using non-sparking tools and materials.

- Eliminating ignition sources, such as open flames and cigarette smoking.

- Ventilating the work area to prevent fuel vapor buildup.

- Following manufacturer’s guidelines and established safety protocols.

6. How do you inspect and maintain aircraft landing gear systems?

Inspection:

- Visually inspecting tires, wheels, brakes, and struts for wear, damage, and leaks.

- Checking tire pressure and tread depth.

- Inspecting brake pads and rotors for wear and proper operation.

- Testing landing gear retraction and extension mechanisms.

Maintenance:

- Replacing or repairing tires, wheels, brakes, and other components as needed.

- Lubricating and adjusting landing gear mechanisms.

- Performing periodic maintenance checks and inspections.

- Following manufacturer’s maintenance schedules and recommendations.

7. Describe your experience in performing aircraft weight and balance calculations.

- Understanding aircraft weight and balance principles and regulations.

- Calculating aircraft weight and center of gravity using various methods, such as weighing scales or computer software.

- Loading aircraft according to weight and balance specifications.

- Ensuring aircraft stability and performance within acceptable limits.

- Documenting weight and balance data for maintenance records.

8. What is your understanding of aircraft structural inspections and NDT techniques?

- Visual inspections using mirrors, borescopes, and other tools to detect cracks, corrosion, and damage.

- Non-destructive testing (NDT) techniques, such as ultrasonic, eddy current, and radiographic testing, to assess aircraft structures without causing damage.

- Interpreting NDT results and making recommendations for repairs or replacements.

- Following established inspection protocols and industry standards.

- Maintaining accurate records of inspections and findings.

9. How do you handle working in a fast-paced and time-sensitive environment, as is often the case in aircraft maintenance?

- Prioritizing tasks based on urgency and importance.

- Working efficiently and effectively within time constraints.

- Communicating clearly and effectively with team members and supervisors.

- Staying organized and managing multiple responsibilities simultaneously.

- Maintaining a positive attitude and maintaining focus under pressure.

10. Describe your experience in working with aircraft maintenance software and documentation systems.

- Using aircraft maintenance software to track maintenance tasks, records, and compliance.

- Referencing technical manuals and maintenance instructions.

- Inputting and retrieving data from maintenance databases.

- Working with electronic flight logs and other digital documentation systems.

- Maintaining proficiency in using industry-standard software and technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Experimental Aircraft Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Experimental Aircraft Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Experimental Aircraft Mechanics are highly skilled professionals responsible for maintaining and repairing experimental aircraft. Their primary duties involve ensuring the safety and airworthiness of these unique aircraft.

1. Maintenance and Inspections

Conduct routine maintenance and inspections to identify potential issues, perform preventative maintenance, and address any detected problems.

- Inspect aircraft components, systems, and structures for defects, wear, and damage.

- Perform maintenance tasks as per manufacturer’s specifications, including lubrication, replacement of parts, and cleaning.

2. Troubleshooting and Repairs

Diagnose and troubleshoot aircraft problems, determine the root cause of malfunctions, and implement appropriate repairs.

- Analyze aircraft systems and components using diagnostic equipment and tools.

- Repair or replace faulty components, assemblies, and systems to restore aircraft functionality.

3. Modifications and Upgrades

Collaborate with engineers and designers to implement modifications and upgrades to experimental aircraft, enhancing their performance and capabilities.

- Install new or modified components, systems, and avionics.

- Test and evaluate aircraft modifications to ensure compliance with safety standards and regulations.

4. Documentation and Record-Keeping

Maintain accurate and detailed records of all maintenance, inspections, and repairs performed on experimental aircraft.

- Document all maintenance actions in accordance with regulatory guidelines and manufacturer’s specifications.

- Prepare and submit maintenance reports, inspection logs, and other relevant documentation.

Interview Tips

To ace the interview for an Experimental Aircraft Mechanic position, candidates should prepare thoroughly and present themselves as highly skilled and knowledgeable professionals.

1. Research the Company and Position

Research the company’s history, culture, and current projects to demonstrate your interest and understanding of their organization.

- Review the job description carefully and identify the key qualifications and responsibilities required.

- Tailor your resume and cover letter specifically to the position, highlighting your relevant skills and experience.

2. Showcase Your Technical Expertise

Emphasize your technical proficiency in aircraft maintenance and repair, including your knowledge of experimental aircraft systems.

- Provide specific examples of complex troubleshooting and repair tasks you have successfully completed.

- Discuss your experience with experimental aircraft modifications and upgrades, and how you ensured compliance with safety standards.

3. Highlight Safety and Quality Assurance

Stress your commitment to safety and quality in all aspects of your work as an aircraft mechanic.

- Explain how you follow industry best practices and regulatory guidelines to maintain the airworthiness of experimental aircraft.

- Describe your experience in documenting maintenance actions and ensuring accurate record-keeping.

4. Demonstrate Communication and Teamwork Skills

Effective communication and teamwork are crucial for Experimental Aircraft Mechanics.

- Provide examples of how you collaborate with engineers, designers, and other mechanics on aircraft projects.

- Discuss your ability to communicate technical information clearly and concisely to both technical and non-technical audiences.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Experimental Aircraft Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.