Are you gearing up for an interview for a Ignition Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Ignition Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ignition Mechanic

1. Explain the function of an ignition system in a vehicle?

An ignition system is a crucial component in a vehicle’s engine, responsible for initiating the combustion process and converting electrical energy into a spark. Here are its primary functions:

- Generate High Voltage: The ignition system generates a high voltage, typically around 10,000 to 30,000 volts, to create a spark at the spark plug.

- Distribute Voltage: The system distributes this high voltage to the correct spark plugs at the appropriate timing for each cylinder.

- Produce Spark: The high voltage creates a spark across the spark plug gap, igniting the air-fuel mixture in the cylinder.

- Control Timing: The ignition system ensures that the spark occurs at the optimal time relative to the piston’s position and engine speed for efficient combustion.

2. Describe the different types of ignition systems used in modern vehicles?

Electronic Ignition Systems:

- Transistorized Coil Ignition (TCI): Uses transistors to control the ignition coil, eliminating the need for a distributor.

- Electronic Distributorless Ignition (EDI): Similar to TCI but uses individual coils for each spark plug, eliminating the distributor cap and rotor.

Distributor-Based Ignition Systems:

- Contact Point Ignition: Employs a mechanical distributor with contact points that open and close to generate a spark.

- Electronic Ignition (EI): Uses an electronic module to control the timing and generation of the spark, replacing the contact points.

3. Explain the working principle of a distributor in a conventional ignition system?

A distributor is a rotating electrical device that distributes high voltage to the spark plugs in the correct firing order. Here’s how it works:

- A camshaft drives the distributor, causing it to rotate in sync with the engine.

- Inside the distributor, a rotor arm rotates with the shaft, making contact with individual terminals connected to the spark plugs.

- As the rotor passes each terminal, it completes the circuit, allowing high voltage to flow to the corresponding spark plug.

- The distributor cap, which sits atop the distributor, ensures that the high voltage is directed to the correct spark plug for each cylinder.

4. How does an ignition coil function within an ignition system?

An ignition coil is a transformer that steps up the voltage from the vehicle’s battery to the high voltage required for ignition. Here’s how it works:

- The coil consists of two windings: a primary winding with a few hundred turns and a secondary winding with thousands of turns.

- When the primary winding is energized by a current from the battery, it creates a magnetic field.

- When the current is interrupted, the magnetic field collapses, inducing a high voltage in the secondary winding.

- This high voltage is then directed to the spark plugs to create the spark necessary for ignition.

5. What are the common signs and symptoms of a faulty ignition system?

- Difficulty Starting: Engine may crank but fail to start or start with hesitation.

- Engine Misfires: Irregular or erratic running of the engine due to missed ignition events.

- Reduced Power and Fuel Efficiency: Inefficient combustion leads to decreased performance and increased fuel consumption.

- Illuminated Check Engine Light: The vehicle’s computer may detect ignition system issues and trigger the CHECK ENGINE light.

- Backfiring: Unburned fuel ignites in the exhaust system, causing loud bangs.

6. Describe the steps involved in diagnosing and repairing an ignition system issue?

- Inspect Components: Visually examine spark plugs, wires, distributor cap, and rotor for damage or wear.

- Test Spark: Use a spark tester to check for spark at the spark plugs.

- Check Ignition Coil: Test the ignition coil’s resistance and voltage output to ensure it’s functioning properly.

- Inspect Distributor (if applicable): Verify the distributor cap and rotor are intact and making proper contact.

- Scan for Codes: Use an OBD-II scanner to retrieve any diagnostic trouble codes related to the ignition system.

- Replace Faulty Components: Based on the diagnosis, replace any defective components, such as spark plugs, wires, ignition coil, or distributor.

7. How do you ensure the proper timing of an ignition system?

- Timing Light: Use a timing light to align the timing marks on the engine’s crankshaft pulley with the specified marks on the timing cover.

- Diagnostic Scanners: Some advanced diagnostic scanners can display live engine data, including ignition timing.

- Manufacturer Specifications: Refer to the vehicle’s repair manual for the correct ignition timing specifications.

8. Explain the concept of ignition advance and its significance?

Ignition advance refers to the timing of the spark relative to the piston’s position. Advancing the ignition timing means the spark occurs earlier in the compression stroke. Here’s its significance:

- Improved Combustion: Advancing the timing allows more time for the air-fuel mixture to burn, resulting in more efficient combustion.

- Increased Power: Optimized ignition timing maximizes the engine’s power output.

- Reduced Emissions: Proper ignition timing reduces unburned fuel and emissions.

9. How does the ignition system interact with other vehicle systems, such as the fuel injection system?

The ignition system works in conjunction with other vehicle systems, including the fuel injection system, to ensure efficient engine operation:

- Synchronizing Ignition and Fuel Injection: The ignition system’s timing is coordinated with the fuel injection system to ensure that fuel is injected at the optimal time relative to the spark.

- Engine Management: The vehicle’s engine control module (ECM) monitors and adjusts both the ignition and fuel injection systems based on engine load, speed, and other factors.

- Diagnostics and Troubleshooting: When an issue arises in either the ignition or fuel injection system, the ECM can identify the problem and trigger diagnostic trouble codes.

10. Describe any recent advancements or trends in automotive ignition systems?

- Direct Ignition Systems: These systems eliminate the distributor, using individual ignition coils mounted directly on each spark plug for more precise ignition control.

- Knock Sensors: Advanced knock sensors detect engine knocking and adjust ignition timing accordingly to prevent damage.

- Variable Valve Timing (VVT): VVT systems optimize engine performance by adjusting the timing of the intake and exhaust valves, which can also impact ignition timing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ignition Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ignition Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ignition Mechanics play a crucial role in ensuring the smooth and efficient operation of internal combustion engines. Their key responsibilities typically include:

1. Ignition System Diagnostics and Repair

Inspecting and diagnosing ignition system components such as spark plugs, ignition coils, and distributors to identify malfunctions and potential issues.

2. Electrical Troubleshooting

Identifying and troubleshooting electrical problems within the ignition system, including wiring, sensors, and control modules, to ensure proper electrical flow and functionality.

3. Engine Performance Analysis

Evaluating engine performance through diagnostic tests and monitoring engine sensors to analyze ignition timing, fuel delivery, and combustion efficiency.

4. Ignition System Upgrades and Modifications

Installing and modifying ignition systems to improve engine performance, fuel efficiency, and overall vehicle responsiveness.

Interview Preparation Tips

To ace an Ignition Mechanic interview, candidates should prepare thoroughly by considering the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, mission, and specific requirements for the Ignition Mechanic position. This knowledge will enable you to demonstrate your understanding of the role and how you align with the company’s needs.

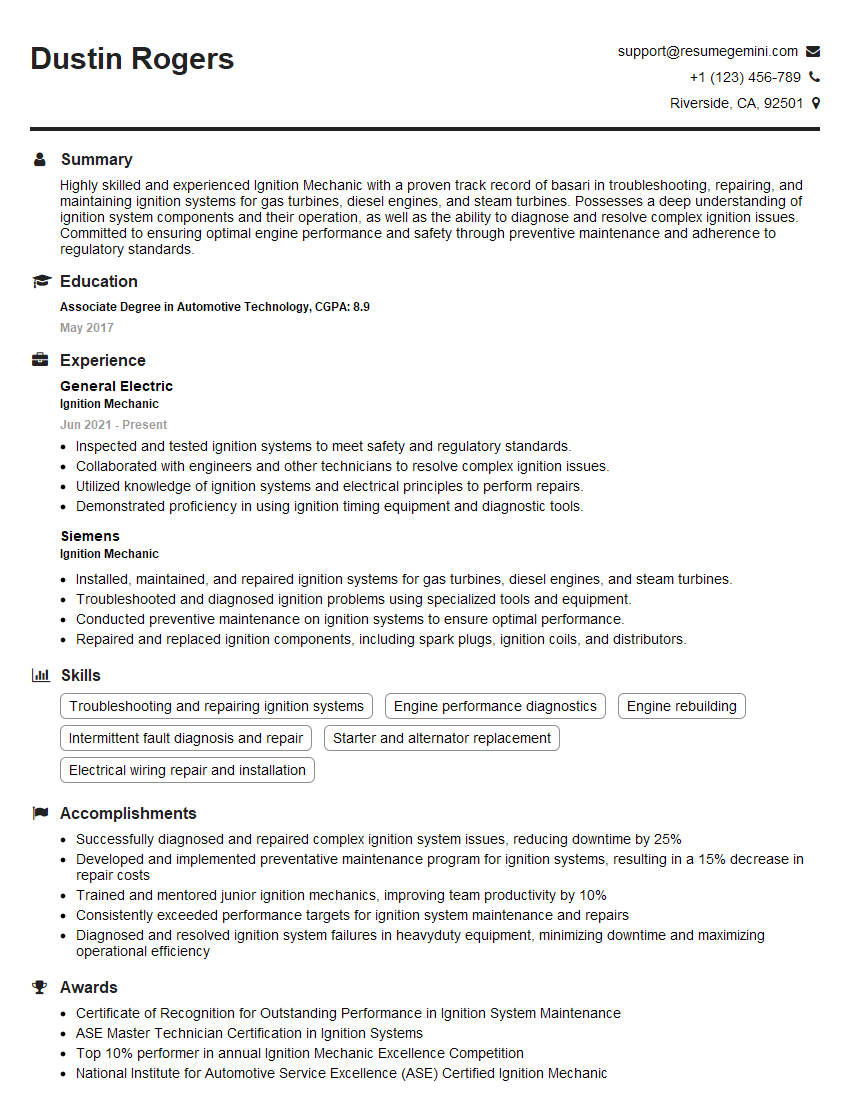

2. Highlight Relevant Skills and Experience

Emphasize your technical proficiency in ignition systems, electrical troubleshooting, and engine performance analysis. Provide specific examples of projects or situations where you successfully diagnosed and repaired ignition-related issues.

3. Showcase Problem-Solving Abilities

Interviewers will be keen on your ability to solve complex ignition problems. Prepare stories or examples that illustrate your analytical skills, logical reasoning, and ability to resolve challenging technical issues.

4. Prepare for Technical Questions

Expect questions that delve into ignition system components, engine performance metrics, and troubleshooting techniques. Study ignition system theory and brush up on diagnostic procedures to confidently answer these technical queries.

5. Dress Professionally and Be Punctual

First impressions matter. Dress appropriately for the interview and arrive on time to demonstrate your respect and professionalism.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ignition Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ignition Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.