Are you gearing up for an interview for a Propeller Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Propeller Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

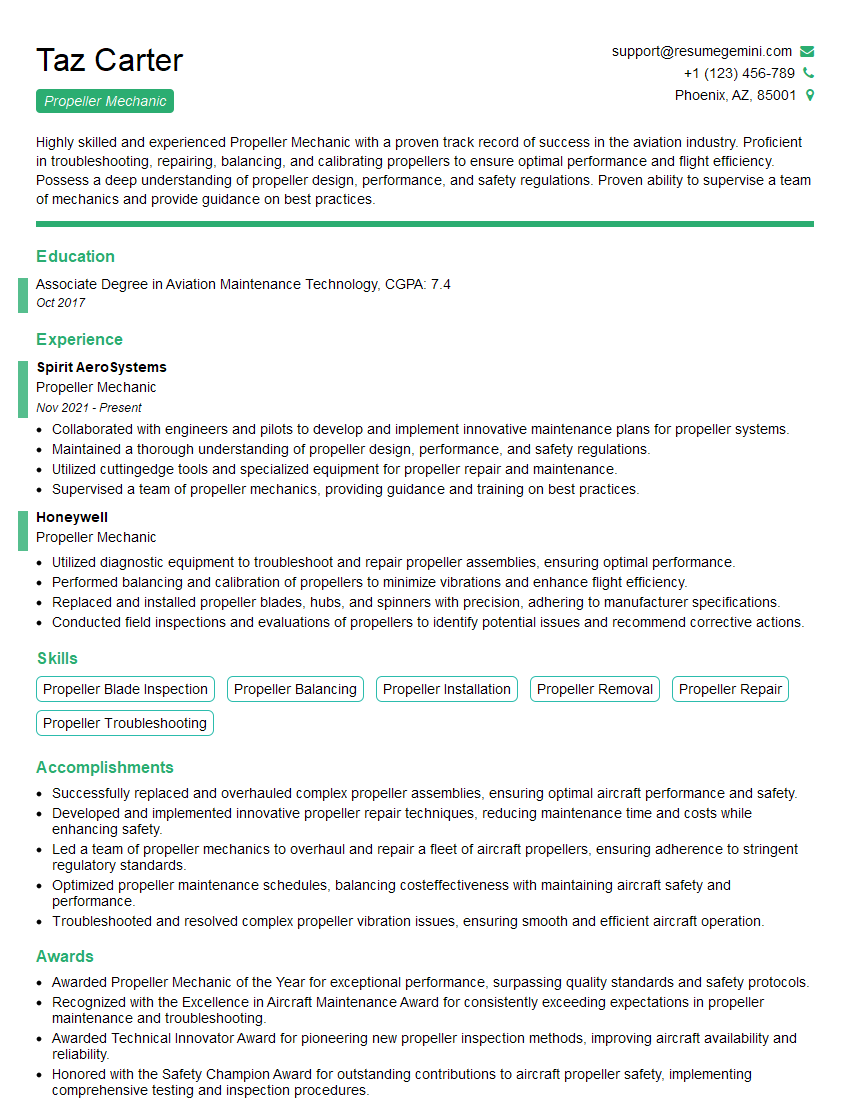

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Propeller Mechanic

1. What are the different types of propellers and their respective applications?

There are various types of propellers, each designed for specific applications. Here are the most common types and their uses:

- Fixed-pitch propellers: These are the simplest type of propellers and are commonly found on smaller boats and outboard motors. They have a fixed blade angle that cannot be adjusted.

- Adjustable-pitch propellers: These propellers allow for the adjustment of the blade angle, enabling the optimization of performance under different conditions. They are often used on larger boats and provide greater control over speed and efficiency.

- Controllable-pitch propellers: These propellers offer the highest level of control, allowing the blade angle to be adjusted while the propeller is in operation. They are typically found on high-performance vessels and provide the most flexibility in terms of performance and maneuverability.

- Surface-piercing propellers: These propellers are designed to operate partially above the water’s surface, reducing drag and increasing efficiency at high speeds. They are commonly used on racing boats and other high-performance applications.

- Ducted propellers: These propellers are enclosed within a duct or shroud, which helps to improve efficiency and protect the propeller from damage. They are often used on thrusters, submarines, and other specialized applications.

2. Describe the process of propeller balancing.

Balancing statically

- Place the propeller on a balancing stand or arbor.

- Mark the heavy point on the propeller.

- Add weight to the opposite side of the heavy point until the propeller is balanced.

Balancing dynamically

- Mount the propeller on a dynamic balancing machine.

- Spin the propeller at a high speed.

- The machine will measure the vibration and indicate the amount and location of any imbalance.

- Add weight to the appropriate location to balance the propeller.

3. Explain the importance of proper propeller alignment and how misalignment can affect performance.

Proper propeller alignment is crucial for optimal performance and to prevent damage to the propeller, shaft, and other components. Misalignment can lead to several negative consequences:

- Reduced efficiency: Misaligned propellers can cause increased drag and reduced thrust, resulting in lower boat speed and fuel efficiency.

- Vibration: Misalignment can cause excessive vibration, which can damage the propeller, shaft, and other components.

- Wear and tear: Misaligned propellers can cause uneven wear on the propeller blades and other components, reducing their lifespan.

- Damage to the driveline: Severe misalignment can put excessive stress on the propeller shaft, couplings, and other components, potentially leading to damage or failure.

4. Describe the methods for troubleshooting common propeller problems, such as cavitation and blade erosion.

Cavitation

- Inspect the propeller for signs of cavitation damage, such as pitting or erosion on the blades.

- Check the propeller size and pitch to ensure they are appropriate for the boat and engine.

- Inspect the propeller shaft and alignment to ensure there is no misalignment or vibration.

- Consider using a propeller with a different blade design or material to reduce cavitation.

Blade erosion

- Inspect the propeller for signs of blade erosion, such as thinning or rounding of the blade edges.

- Check the propeller for signs of impact damage, such as nicks or gouges.

- Inspect the propeller shaft and alignment to ensure there is no misalignment or vibration.

- Consider using a propeller with a more durable blade material or a sacrificial anode to protect the propeller from erosion.

5. What are the safety precautions that should be followed when working with propellers?

- Always wear appropriate safety gear, including gloves and eye protection.

- Never work on a propeller while the engine is running.

- Secure the boat and propeller before starting any work.

- Use proper tools and techniques to avoid damaging the propeller or injuring yourself.

- Be aware of the location of other people and objects in the area.

- If you are not comfortable working on a propeller, seek assistance from a qualified marine mechanic.

6. How do you determine the correct propeller size and pitch for a particular boat and engine combination?

To determine the correct propeller size and pitch, consider the following factors:

- Boat weight and size: Heavier and larger boats require larger propellers.

- Engine horsepower and torque: More powerful engines require larger propellers with a lower pitch.

- Boat speed and desired performance: For higher speeds, use a smaller propeller with a higher pitch.

- Propeller slip: The difference between the theoretical and actual speed of the boat, which affects the propeller’s efficiency.

It is recommended to consult with a marine professional or use a propeller sizing calculator to determine the optimal propeller size and pitch for your specific boat and engine combination.

7. Explain the difference between a right-hand and a left-hand propeller.

A right-hand propeller turns clockwise when viewed from behind the boat, while a left-hand propeller turns counterclockwise. The direction of rotation is determined by the blade design and the way the propeller is installed on the shaft. It is important to use the correct type of propeller for your boat, as using the wrong one can affect performance and handling.

8. What are the factors that can affect propeller efficiency?

- Propeller size and pitch: Choosing the correct size and pitch is crucial for optimizing efficiency.

- Propeller design: Blade shape, number of blades, and materials used can impact efficiency.

- Propeller condition: Damaged or fouled propellers can significantly reduce efficiency.

- Boat speed and load: Different speeds and loads require different propeller designs for maximum efficiency.

- Hull design and underwater shape: The boat’s hull and underwater shape can influence propeller efficiency.

9. How do you inspect a propeller for damage or wear?

- Visually inspect the propeller for nicks, dents, cracks, or other damage.

- Check the blade edges for any thinning, rounding, or erosion.

- Look for signs of cavitation damage, such as pitting or erosion on the blade surfaces.

- Inspect the propeller hub for any damage or corrosion.

- Check the propeller shaft and alignment to ensure there is no misalignment or vibration.

10. What are the different types of propeller materials and their advantages and disadvantages?

- Aluminum: Lightweight, affordable, and relatively durable, but prone to corrosion and damage.

- Stainless steel: More durable and corrosion-resistant than aluminum, but heavier and more expensive.

- Bronze: Durable, corrosion-resistant, and can be repaired more easily than other materials, but heavy and expensive.

- Composite: Lightweight, durable, and corrosion-resistant, but can be more expensive than traditional materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Propeller Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Propeller Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Propeller Mechanics are responsible for the maintenance, repair, and overhaul of aircraft propellers, ensuring their safe and efficient operation.

1. Propeller Maintenance and Inspection

Inspect propellers for damage, wear, or corrosion using visual and non-destructive testing techniques

- Perform scheduled maintenance tasks as defined by the aircraft manufacturer’s maintenance program

- Lubricate and adjust propeller components

2. Propeller Repair and Overhaul

Repair or replace damaged or worn propeller components, including blades, hubs, and governors

- Balance and track propellers to ensure proper operation

- Overhaul propellers as required, involving complete disassembly, inspection, and reassembly

3. Troubleshooting and Diagnostics

Troubleshoot and diagnose problems with propellers and associated systems

- Analyze vibration and noise data

- Identify and rectify faults in propeller control systems

4. Record Keeping and Documentation

Maintain accurate and up-to-date records of propeller maintenance, repairs, and overhauls

- Prepare and submit maintenance reports

- Maintain a clean and organized work area

Interview Tips

To ace the interview, candidates should thoroughly prepare and demonstrate a deep understanding of propeller mechanics and their role in aircraft maintenance.

1. Research the Company and Position

Familiarize yourself with the company’s business, aircraft fleet, and maintenance practices

- Review the job description and identify specific requirements

- Research industry trends and best practices in propeller maintenance

2. Highlight Relevant Skills and Experience

Emphasize your knowledge of propeller systems, maintenance techniques, and troubleshooting procedures.

- Quantify your experience in hours or projects completed

- Provide specific examples of your problem-solving and critical thinking abilities

3. Showcase Safety and Quality Standards

Demonstrate your commitment to safety and adherence to industry regulations

- Explain your understanding of FAA regulations and maintenance manuals

- Highlight your experience in using specialized tools and equipment

4. Prepare for Technical Questions

Be prepared to answer technical questions related to propeller systems, maintenance procedures, and troubleshooting

- Review common problems and solutions for propellers

- Practice explaining complex technical concepts in a clear and concise manner

5. Practice Your Communication Skills

Speak confidently and articulate your thoughts effectively

- Practice answering questions in a STAR format (Situation, Task, Action, Result)

- Be prepared to ask questions to demonstrate your interest and engagement

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Propeller Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!