Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Propeller-Driven Airplane Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

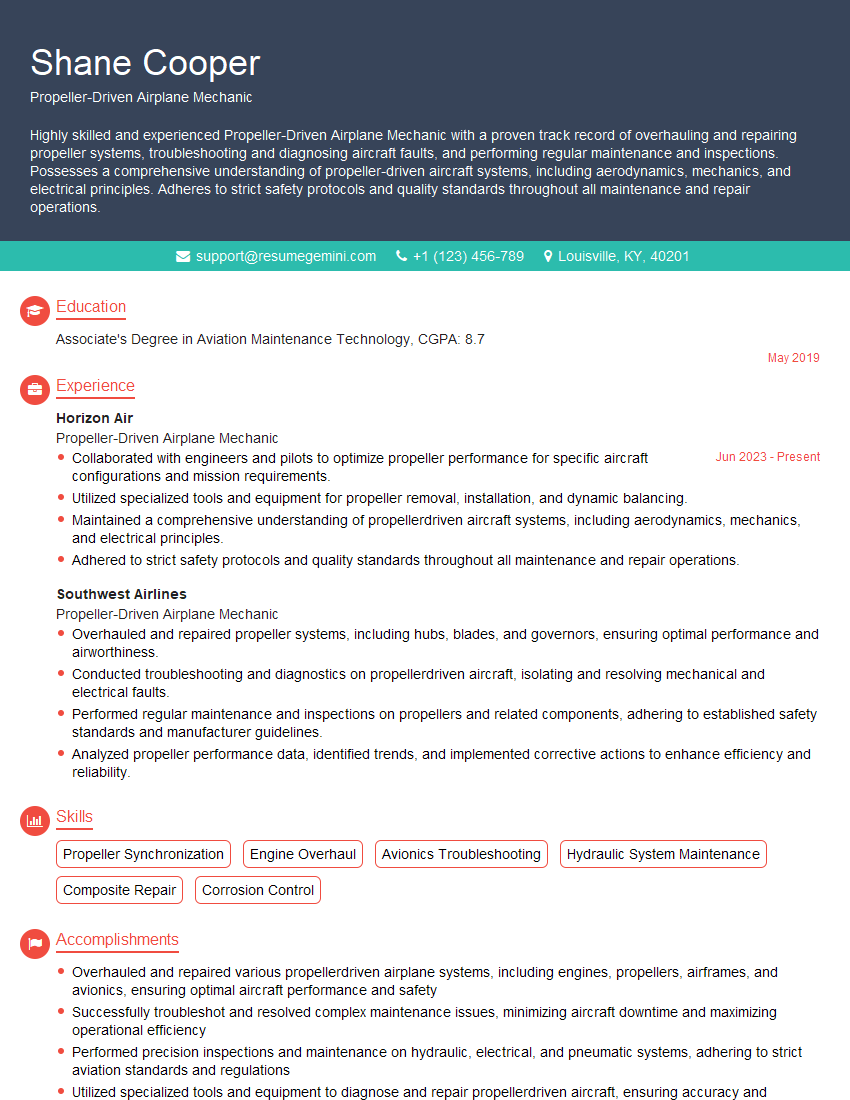

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Propeller-Driven Airplane Mechanic

1. Describe the process of inspecting and cleaning a propeller?

The process involves the following steps:

- Inspecting the propeller for any damage, cracks, or corrosion.

- Cleaning the propeller using an approved cleaning agent and a soft brush.

- Applying a protective coating to the propeller to prevent corrosion.

2. What are the different types of propellers used on propeller-driven airplanes?

Fixed-pitch propellers

- Have blades that are fixed at a specific pitch angle.

- Are used on low-power airplanes and for training purposes.

Variable-pitch propellers

- Have blades that can be adjusted to change the pitch angle.

- Are used on high-performance airplanes to optimize efficiency and performance.

Constant-speed propellers

- Are a type of variable-pitch propeller that automatically adjusts the pitch angle to maintain a constant propeller speed.

- Are used on high-performance airplanes to maximize efficiency and reduce noise.

3. What is the purpose of a spinner on a propeller?

A spinner is a cone-shaped fairing that is mounted on the front of a propeller hub.

- Reduces drag by streamlining the airflow around the propeller.

- Protects the propeller hub and blades from damage caused by debris.

4. What are the common causes of propeller vibration?

- Unbalanced propeller

- Bent or damaged propeller blades

- Loose propeller hub

- Misaligned engine or propeller shaft

5. What are the safety precautions that must be taken when working on propellers?

- Always chock the wheels of the airplane to prevent it from moving.

- Disconnect the battery to prevent the propeller from starting accidentally.

- Use proper tools and equipment to avoid damaging the propeller.

- Wear appropriate safety gear, such as gloves and safety glasses.

6. Describe the different types of propeller governor systems.

Mechanical governors

- Use a centrifugal force mechanism to control the propeller speed.

- Are relatively simple and reliable.

Hydromechanical governors

- Use a combination of mechanical and hydraulic components to control the propeller speed.

- Are more complex than mechanical governors but offer more precise control.

Electronic governors

- Use electronic sensors and actuators to control the propeller speed.

- Are the most advanced type of propeller governor and offer the most precise control.

7. What is the purpose of a propeller feathering system?

A propeller feathering system allows the propeller blades to be turned parallel to the airflow, reducing drag.

- Used in emergencies, such as engine failure, to reduce drag and improve glide performance.

- Also used during maintenance to prevent the propeller from rotating during engine operation.

8. What are the different types of propeller balancing methods?

Static balancing

- Measures the weight distribution of the propeller along its axis of rotation.

- Used to identify and correct any imbalances that may cause vibration.

Dynamic balancing

- Measures the propeller’s response to centrifugal forces while it is rotating.

- Used to identify and correct any imbalances that may cause vibration at specific operating speeds.

9. What are the common troubleshooting steps for a propeller that is not functioning properly?

- Inspect the propeller for any damage or debris.

- Check the propeller hub and shaft for any looseness or misalignment.

- Inspect the propeller governor system for any malfunctions.

- Check the engine and propeller shaft for any vibrations.

10. What are the latest advancements in propeller design and technology?

- Composite propellers: Made from lightweight and durable composite materials.

- Scimitar propellers: Designed with curved blades to reduce noise and improve efficiency.

- Adaptive propellers: Can change their pitch angle in flight to optimize performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Propeller-Driven Airplane Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Propeller-Driven Airplane Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Propeller-driven airplane mechanics are responsible for maintaining and repairing propeller-driven aircraft. They perform a variety of tasks, including:

1. Inspecting aircraft

Inspecting aircraft for damage, wear and tear, and other problems.

2. Maintaining aircraft

- Performing routine maintenance, such as changing oil and filters, and lubricating moving parts.

- Replacing worn or damaged parts

- Making repairs to aircraft structures

3. Overhauling aircraft

- Performing major repairs and upgrades to aircraft

- Replacing engines, propellers, and other major components

4. Troubleshooting aircraft problems

- Diagnosing and repairing aircraft problems

- Performing tests to ensure that aircraft are functioning properly

5. Certifying aircraft

- Inspecting and certifying aircraft to ensure that they meet safety standards

- Signing off on repairs and maintenance

Interview Tips

To prepare for an interview for a Propeller-Driven Airplane Mechanic position, you should follow these tips:

1. Research the company and the position

- Learn about the company’s history, culture, and products or services.

- Read the job description carefully and identify the key requirements for the position.

2. Practice your answers to common interview questions

- Prepare answers to questions about your experience, skills, and qualifications.

- Practice your answers to behavioral questions, which ask you to describe how you handled specific situations in the past.

3. Dress appropriately

- Dress in business attire or other appropriate clothing for the position you are interviewing for.

- Make sure your clothes are clean, pressed, and fit well.

4. Be on time for your interview

- Plan to arrive for your interview 10-15 minutes early.

- This will give you time to check in, find your interview room, and relax before your interview begins.

5. Be prepared to ask questions

- At the end of the interview, you will likely be given the opportunity to ask questions.

- This is a great opportunity to learn more about the company and the position, and to show that you are interested in the position.

Next Step:

Now that you’re armed with the knowledge of Propeller-Driven Airplane Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Propeller-Driven Airplane Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini