Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Automotive Brake Adjuster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

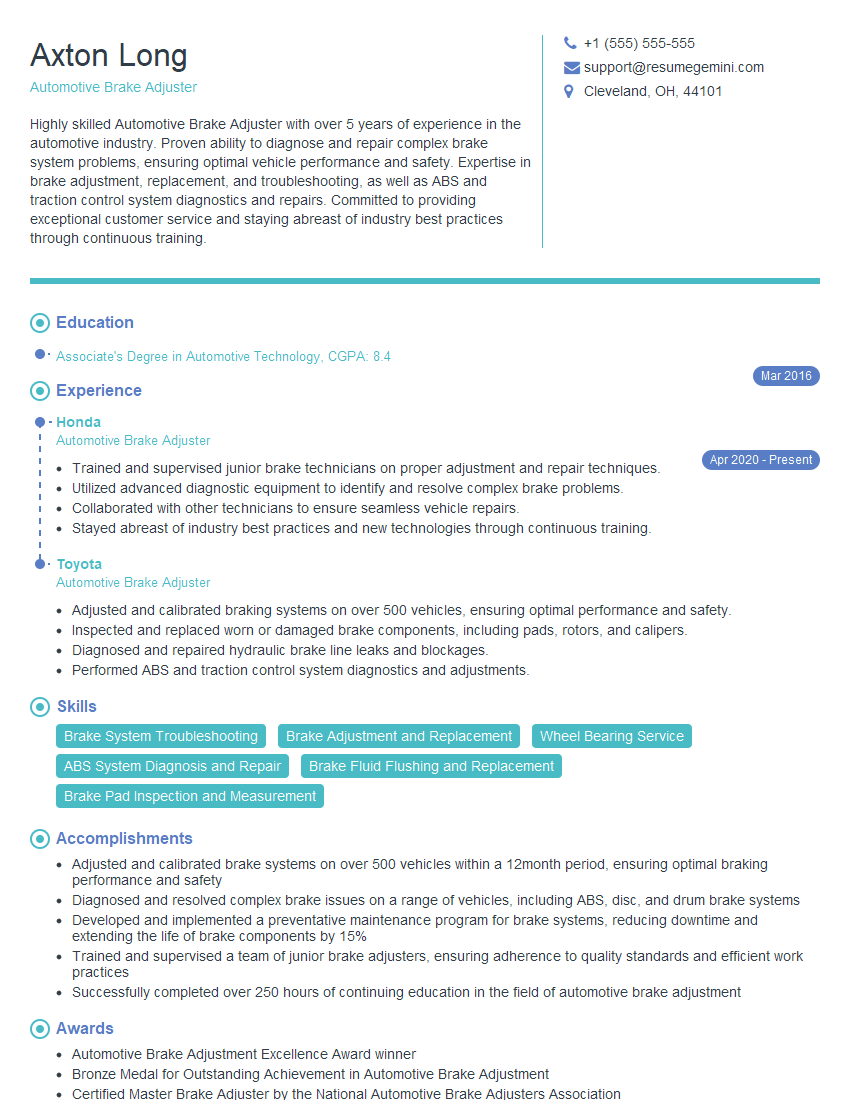

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automotive Brake Adjuster

1. Explain the working principle of a hydraulic brake system.

A hydraulic brake system converts the force applied to the brake pedal into hydraulic pressure, which is then used to actuate the brake calipers or wheel cylinders. Here’s a step-by-step explanation of the working principle:

- When the driver presses the brake pedal, it activates the master cylinder.

- The master cylinder contains a piston that moves within a cylinder bore, creating hydraulic pressure in the brake fluid.

- The hydraulic pressure travels through brake lines to the brake calipers or wheel cylinders.

- In the brake calipers or wheel cylinders, the hydraulic pressure acts on pistons, which in turn push the brake pads against the brake rotors or brake drums.

- The friction between the brake pads and rotors or drums slows down the rotation of the wheels, thereby stopping the vehicle.

2. Describe the different types of brake adjusters and their applications.

There are primarily two types of brake adjusters used in automotive brake systems:

Manual Brake Adjusters

- Used in older vehicles and typically require periodic manual adjustment to compensate for brake pad wear.

- Involve loosening a locknut, turning an adjuster screw, and retightening the locknut.

Automatic Brake Adjusters

- Found in most modern vehicles and automatically adjust the brakes as the pads wear.

- Utilize a ratchet mechanism or a worm gear to advance the adjuster screw when the brake pedal is applied.

3. Explain the purpose and operation of a brake proportioning valve.

A brake proportioning valve is a device that regulates the hydraulic pressure applied to the rear brakes, ensuring a balanced braking effort between the front and rear wheels.

- Prevents the rear wheels from locking up prematurely, which can lead to skidding.

- Operates based on the load carried by the vehicle. When the vehicle is heavily loaded, the proportioning valve increases the pressure to the rear brakes.

- When the vehicle is lightly loaded, the proportioning valve reduces the pressure to the rear brakes.

4. Discuss the importance of brake fluid and its properties.

Brake fluid plays a crucial role in hydraulic brake systems, transmitting the pressure from the master cylinder to the calipers or wheel cylinders.

- Must have a high boiling point to prevent vaporization, which can lead to brake failure.

- Must be able to resist corrosion and maintain viscosity over a wide temperature range.

- Should be hygroscopic, meaning it absorbs moisture to prevent brake system corrosion.

- Regular brake fluid changes are recommended to maintain optimal performance.

5. Describe the symptoms and potential causes of brake pedal pulsation.

Brake pedal pulsation refers to a vibration or shudder felt through the brake pedal when braking.

Symptoms

- Vibration in the brake pedal under braking

- May be accompanied by a squealing or grinding noise

Potential Causes

- Warped brake rotors

- Uneven brake pad wear

- Damaged wheel bearings

- Loose or damaged brake components

6. Explain the difference between ABS and non-ABS brake systems.

ABS (Anti-lock Braking System) is an advanced brake system that prevents the wheels from locking up during braking, allowing the driver to maintain control of the vehicle.

ABS Brake System

- Uses wheel speed sensors to detect when a wheel is about to lock up.

- Modulates the brake pressure to that wheel, allowing it to continue rotating.

- Provides improved stability and control during braking, especially on slippery surfaces.

Non-ABS Brake System

- Does not have wheel speed sensors or the ability to modulate brake pressure.

- If the driver applies excessive braking force, the wheels may lock up, causing the vehicle to skid.

- Less effective at maintaining control during braking on slippery surfaces.

7. Discuss the potential hazards and safety precautions when working with brake systems.

Working with brake systems requires attention to safety due to the presence of hydraulic pressure and potential hazards.

Potential Hazards

- Hydraulic pressure can cause injuries if brake lines or components fail.

- Brake fluid is toxic and can irritate skin and eyes.

- Brake dust contains harmful particles that can be inhaled.

Safety Precautions

- Wear appropriate safety gear, including gloves, eye protection, and a mask.

- Ensure the vehicle is properly secured before working on the brake system.

- Release hydraulic pressure before disconnecting any brake lines or components.

- Handle brake fluid with care and dispose of it properly.

8. Describe the proper procedure for bleeding brakes to remove air from the system.

Bleeding brakes involves removing air bubbles from the brake system to ensure proper operation and prevent spongy brake pedal feel.

- Gather necessary tools and materials, including a brake bleeder wrench, clear tubing, and a container for brake fluid.

- Identify the bleeder screws on each brake caliper or wheel cylinder.

- Attach one end of the clear tubing to the bleeder screw and the other end to the container.

- Have an assistant slowly pump the brake pedal while you open the bleeder screw slightly.

- Close the bleeder screw when fluid starts to flow out without any bubbles.

- Repeat the process for each brake caliper or wheel cylinder until all air bubbles are removed.

9. Explain the importance of proper wheel alignment and its impact on brake performance.

Wheel alignment refers to the angles at which the wheels are positioned relative to the vehicle’s chassis.

- Proper wheel alignment ensures even tire wear and reduces rolling resistance.

- Improper wheel alignment can cause uneven brake pad wear, reduced braking efficiency, and premature brake component failure.

- Regular wheel alignments are recommended to maintain optimal brake performance and overall vehicle safety.

10. Discuss the latest advancements in automotive brake technology, such as electronic brake control systems and regenerative braking.

Modern automotive brake systems incorporate advanced technologies to enhance safety, performance, and efficiency.

Electronic Brake Control Systems

- Utilize electronic sensors and actuators to control brake pressure and distribution.

- Provide features such as ABS, traction control, and stability control.

Regenerative Braking

- Captures energy during braking and stores it in a battery.

- Helps reduce fuel consumption and extends brake component life.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automotive Brake Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automotive Brake Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Automotive Brake Adjusters play a crucial role in ensuring optimal vehicle performance and safety. Their responsibilities encompass a wide range of tasks, including:

1. Diagnosing and Repairing Brake Problems

In-depth understanding of brake systems to accurately identify and resolve issues such as worn pads, faulty calipers, and leaking lines. Utilizes specialized tools and equipment for comprehensive diagnostics and repairs. Maintains up-to-date knowledge of industry best practices and follows safety protocols meticulously.

2. Performing Brake Adjustments

Expert in adjusting brake components to ensure proper alignment and optimal braking performance. Thoroughly inspects brake pads, shoes, and rotors for wear and tear. Makes precise adjustments to eliminate noise, vibration, and other brake-related issues. Ensures adherence to manufacturer specifications and industry standards.

3. Inspecting and Replacing Brake Parts

Regularly inspects brake pads, rotors, calipers, and other components for signs of wear or damage. Proficiently replaces worn or damaged parts to maintain brake system integrity. Follows established procedures for proper installation and ensures adherence to safety guidelines. Monitors inventory levels and orders replacement parts as needed.

4. Providing Customer Service

Excellent communication and interpersonal skills to effectively interact with customers. Provides clear explanations of brake problems and repair procedures. Builds strong relationships with customers by addressing their concerns and providing exceptional service. Maintains a professional and courteous demeanor at all times.

Interview Tips

Preparation is key to acing an interview for an Automotive Brake Adjuster position. Here are some valuable tips and hacks to help candidates excel:

1. Research the Company and the Position

Thoroughly research the automotive industry, the company you’re applying to, and the specific responsibilities of the Brake Adjuster role. This demonstrates your genuine interest in the position and sets you apart from other candidates. Familiarize yourself with the company’s history, mission, and values to align your responses with their culture.

2. Highlight Your Technical Skills

Emphasize your expertise in brake system diagnostics and repairs. Provide specific examples of complex brake issues you’ve successfully resolved. Quantify your accomplishments whenever possible to demonstrate your impact. Showcase your proficiency in using specialized tools and equipment, and highlight any relevant certifications or training you’ve obtained.

3. Demonstrate Your Customer Service Orientation

Automotive Brake Adjusters interact directly with customers, so it’s crucial to convey your strong customer service skills. Share anecdotes that illustrate your ability to effectively communicate with clients, build rapport, and resolve their concerns promptly and courteously. Emphasize your attention to detail and commitment to customer satisfaction.

4. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the role. Prepare questions that focus on the company’s growth plans, industry trends, or specific aspects of the Brake Adjuster position. This demonstrates your enthusiasm for the opportunity and allows you to gather more information to make an informed decision.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automotive Brake Adjuster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!