Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Automotive Brake Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Automotive Brake Technician so you can tailor your answers to impress potential employers.

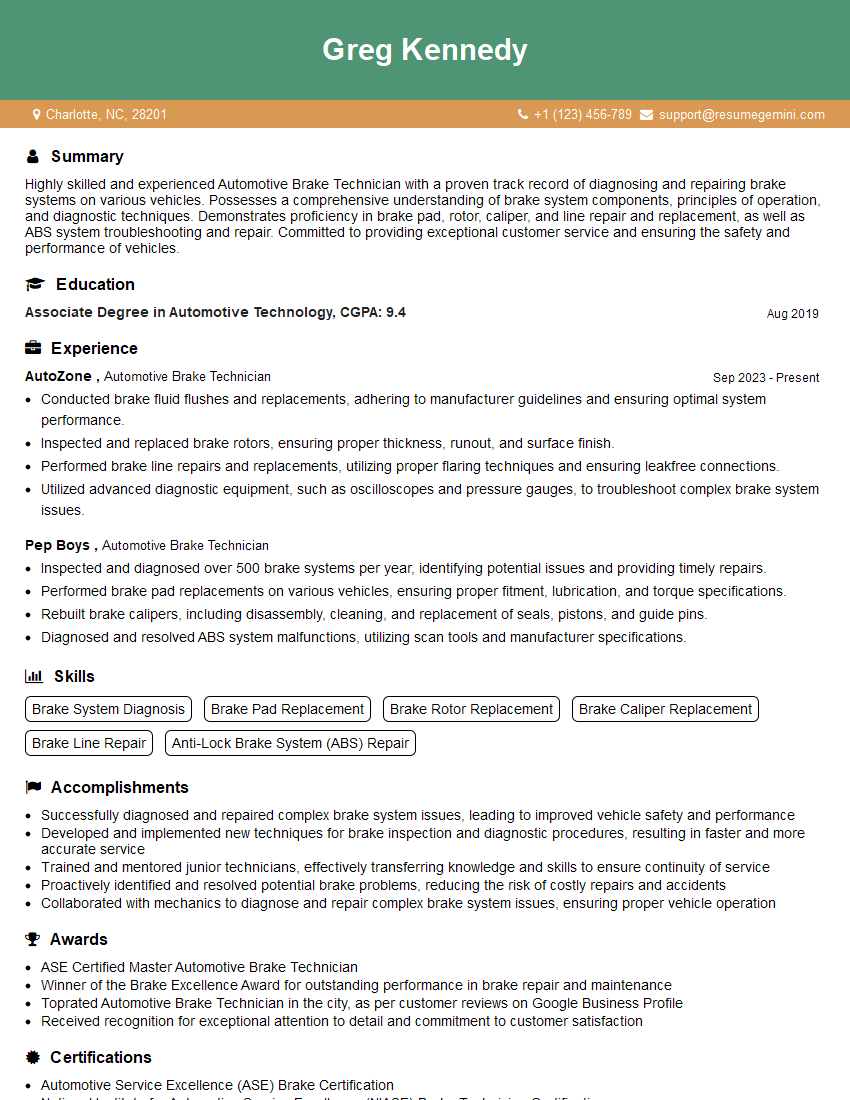

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automotive Brake Technician

1. Explain the working principle of hydraulic brake system.

- Hydraulic brake system uses brake fluid to transfer the force applied by the brake pedal to the brake calipers or wheel cylinders.

- When the brake pedal is pressed, the master cylinder creates hydraulic pressure which is transmitted through the brake lines to the brake calipers or wheel cylinders.

- The pressure in the calipers or wheel cylinders then forces the brake pads or shoes against the brake rotors or drums, creating friction to slow down or stop the vehicle.

2. Describe the different types of brake calipers.

Fixed caliper

- Fixed calipers are mounted rigidly to the suspension or axle.

- They have two pistons, one on each side of the brake rotor.

- When the brake pedal is pressed, the pistons extend and force the brake pads against the rotor.

Floating caliper

- Floating calipers are mounted to a bracket that slides on the suspension or axle.

- They have only one piston, which is located on one side of the brake rotor.

- When the brake pedal is pressed, the piston extends and forces the brake pads against the rotor.

3. Explain the purpose of brake fluid and its maintenance.

- Brake fluid is a hydraulic fluid that transfers the force applied by the brake pedal to the brake calipers or wheel cylinders.

- It must be able to withstand high temperatures and pressures, and it must not corrode the brake system components.

- Brake fluid should be flushed and replaced regularly, as it can absorb moisture over time, which can lead to corrosion and brake failure.

4. Describe the different types of brake pads and their applications.

- Organic brake pads are made of a mixture of organic materials, such as rubber, kevlar, and carbon.

- They are relatively inexpensive and provide good braking performance in most applications.

- Ceramic brake pads are made of a mixture of ceramic materials, such as silicon carbide and aluminum oxide.

- They are more expensive than organic brake pads, but they offer better braking performance, especially in high-performance applications.

- Metallic brake pads are made of a mixture of metal materials, such as iron, copper, and steel.

- They are the most expensive type of brake pad, but they offer the best braking performance, especially in extreme conditions.

5. Explain the purpose and operation of an anti-lock braking system (ABS).

- ABS is a safety system that prevents the wheels from locking up during braking.

- It uses sensors to monitor the speed of each wheel, and it modulates the brake pressure to each wheel to prevent it from locking up.

- ABS allows the driver to maintain control of the vehicle during braking, even on slippery surfaces.

6. Describe the different types of brake rotors and their applications.

- Solid brake rotors are made of a single piece of metal.

- They are the most common type of brake rotor and are used in most passenger cars.

- Vented brake rotors have a series of curved vanes cast into the rotor.

- These vanes help to dissipate heat, which can improve braking performance.

- Cross-drilled brake rotors have a series of holes drilled through the rotor.

- These holes help to further dissipate heat and can also improve braking performance.

7. Explain the importance of proper brake maintenance and what are the signs of potential brake problems?

- Proper brake maintenance is essential for the safety of the vehicle and its occupants.

- Brake pads and rotors should be inspected and replaced regularly, as worn or damaged brakes can lead to reduced braking performance or even brake failure.

- Signs of potential brake problems include:

- Squealing or grinding noises when braking

- Vibrations in the brake pedal or steering wheel

- Extended stopping distances

- Leaking brake fluid

8. Describe the different types of brake lines and their applications.

- Steel brake lines are the most common type of brake line.

- They are made of steel tubing and are relatively inexpensive.

- Stainless steel brake lines are more expensive than steel brake lines, but they are more resistant to corrosion.

- Rubber brake lines are made of a flexible rubber material.

- They are used in applications where there is a need for flexibility, such as in the suspension or steering system.

9. Explain the purpose and operation of a brake proportioning valve.

- A brake proportioning valve is a device that helps to distribute the braking force between the front and rear wheels.

- It is used to prevent the rear wheels from locking up before the front wheels, which can lead to loss of control of the vehicle.

- The brake proportioning valve works by regulating the hydraulic pressure to the rear brakes.

10. Describe the different types of brake master cylinders and their applications.

- Single-circuit brake master cylinders are the most common type of brake master cylinder.

- They have a single piston that moves in one direction to apply hydraulic pressure to all four wheels.

- Dual-circuit brake master cylinders have two pistons, one for the front brakes and one for the rear brakes.

- This design provides redundancy in the event of a failure in one of the circuits.

- Tandem brake master cylinders have two pistons that are arranged in series.

- This design provides a higher level of redundancy than dual-circuit brake master cylinders.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automotive Brake Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automotive Brake Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automotive Brake Technician is responsible for the diagnosis, repair, maintenance, and inspection of automotive brake systems.

1. Inspect and Diagnose Brake Problems

Technicians examine brake pads and shoes for wear and tear, check brake fluid levels and condition, inspect brake lines and hoses for leaks or damage, and test brake system performance to identify any issues.

2. Repair and Replace Brake Components

They repair or replace brake pads and shoes, disc rotors, brake calipers, master cylinders, wheel cylinders, and other brake components as needed.

3. Bleed Brake Systems

Technicians bleed brake systems to remove any air or debris that may cause spongy or ineffective braking.

4. Adjust Brake Systems

They adjust brake systems by adjusting brake pedal free play and parking brake cables to ensure proper brake operation.

5. Perform Brake Maintenance

Technicians perform regular brake maintenance, such as cleaning and lubricating brake components, topping up brake fluid, and inspecting brake lines and hoses.

Interview Tips

To ace an interview for an Automotive Brake Technician position, candidates should:

1. Research the Company and Position

Investigate the company’s history, values, and the specific responsibilities of the position to demonstrate your interest and knowledge.

2. Highlight Relevant Skills and Experience

Emphasize your experience in brake system diagnosis, repair, and maintenance, and mention any relevant certifications or training.

3. Use Specific Examples

Quantify your accomplishments and provide specific examples of your work to demonstrate your abilities.

4. Be Prepared to Discuss Safety Procedures

Familiarity with safety regulations and procedures for working with brake systems is crucial.

5. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”

6. Dress Professionally

First impressions matter, so dress professionally and arrive on time for your interview.

7. Be Enthusiastic and Confident

Demonstrate your passion for automotive repair and your confidence in your abilities to succeed in the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automotive Brake Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.