Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Heavy Repairer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Heavy Repairer so you can tailor your answers to impress potential employers.

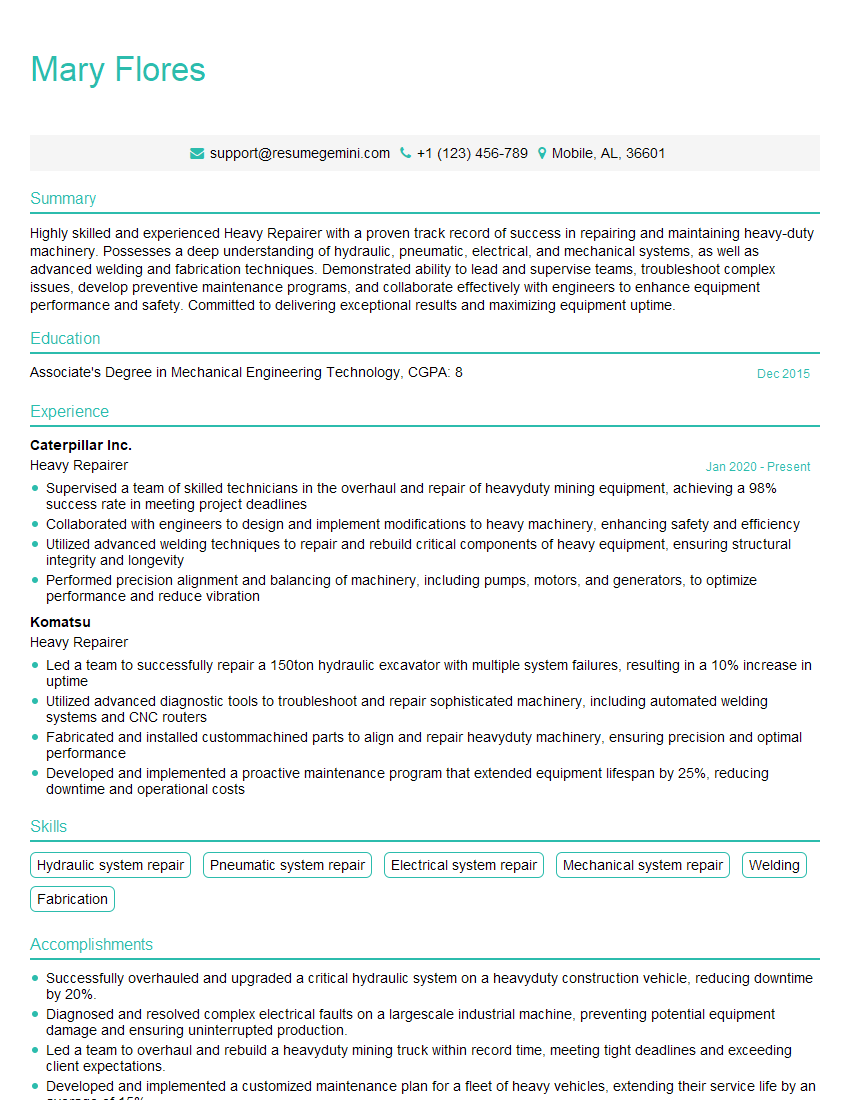

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heavy Repairer

1. Explain the process of diagnosing and repairing a hydraulic system on a heavy vehicle?

The process of diagnosing and repairing a hydraulic system on a heavy vehicle involves several steps:

- Inspection: Visually inspect the system for leaks, damage, or loose connections. Check fluid levels and condition.

- Pressure testing: Use a pressure gauge to test the system pressure at various points to identify restrictions or leaks.

- Flow testing: Measure the flow rate of the hydraulic fluid to determine if there are any blockages or restrictions.

- Component testing: Test individual components such as pumps, valves, and cylinders to identify any faulty or worn parts.

- Repair/replacement: Based on the diagnosis, replace or repair any damaged or faulty components.

- System bleeding: Remove air from the system by bleeding it to ensure proper operation.

- Retesting: Re-test the system after repairs to verify proper functionality and pressure.

2. What are the key factors to consider when selecting a replacement engine for a heavy vehicle?

Engine specifications

- Horsepower and torque requirements

- Displacement and compression ratio

- Emission standards compliance

Vehicle compatibility

- Engine mount points and dimensions

- Driveline and transmission compatibility

- Electrical and fuel system compatibility

Reliability and durability

- Manufacturer reputation and warranty

- Engine design and construction

- Maintenance and repair costs

3. How do you troubleshoot and repair electrical systems on heavy vehicles?

Troubleshooting and repairing electrical systems on heavy vehicles involves a systematic approach:

- Visual inspection: Check for loose or damaged wires, connectors, and fuses.

- Electrical testing: Use a multimeter to test voltage, continuity, and resistance at various points in the circuit.

- Schematic analysis: Refer to the vehicle’s electrical schematic to trace the circuit and identify potential issues.

- Component testing: Test individual components such as batteries, alternators, and sensors to identify any faults.

- Repair/replacement: Replace or repair any damaged or faulty components.

- System testing: Verify the functionality of the repaired system by testing its operation.

4. Describe the different types of welding techniques used in heavy vehicle repair?

- MIG welding (Metal Inert Gas): Uses a consumable wire electrode and a shielding gas to produce an arc.

- TIG welding (Tungsten Inert Gas): Uses a non-consumable tungsten electrode and a shielding gas to create an arc.

- Stick welding (Shielded Metal Arc Welding): Uses a consumable stick electrode that melts to form the weld.

- Oxy-fuel welding: Uses a mixture of oxygen and acetylene gases to produce a flame.

- Plasma cutting: Uses a plasma arc to cut or shape metal.

5. How do you ensure safety when working on heavy vehicles?

- Personal protective equipment (PPE): Wear proper PPE such as safety glasses, gloves, and a hard hat.

- Vehicle stabilization: Use wheel chocks and jack stands to stabilize the vehicle before working underneath.

- Electrical safety: Disconnect the battery and lock out electrical systems before working on them.

- Hot engine precautions: Allow the engine to cool before performing repairs or maintenance.

- Lifting equipment: Use proper lifting equipment such as jacks, cranes, and hoists to lift heavy components.

6. What are the common causes of transmission problems in heavy vehicles?

- Clutch issues: Worn or damaged clutch plates, pressure plates, or release bearings.

- Gear wear: Worn or damaged gears, bearings, or synchronizers.

- Hydraulic system problems: Leaks, contamination, or faulty components in the hydraulic system.

- Electrical issues: Faulty sensors, wiring, or control modules.

- Overloading or improper operation: Exceeding the vehicle’s weight capacity or overloading the transmission.

7. How do you diagnose and repair suspension problems on heavy vehicles?

Diagnosing and repairing suspension problems on heavy vehicles involves the following steps:

- Inspection: Check for obvious signs of damage or wear on suspension components such as springs, shock absorbers, and bushings.

- Ride test: Take the vehicle for a test drive to evaluate its handling and stability.

- Alignment check: Use an alignment machine to check the vehicle’s alignment and adjust if necessary.

- Component testing: Test individual suspension components such as springs, shock absorbers, and bushings to identify any faults.

- Repair/replacement: Replace or repair any damaged or worn components.

- Retesting: Re-test the vehicle’s handling and stability after repairs to verify proper functionality.

8. What are the different types of hydraulic systems used in heavy vehicles and their applications?

- Open-center hydraulic systems: Used for low-pressure applications such as power steering and brakes.

- Closed-center hydraulic systems: Used for high-pressure applications such as lift cylinders and winches.

- Load-sensing hydraulic systems: Used to adjust the system pressure based on the load, improving efficiency.

- Variable-displacement hydraulic systems: Used to adjust the pump output based on the system demand, reducing energy consumption.

9. How do you maintain and service hydraulic systems in heavy vehicles?

- Regular inspections: Check for leaks, contamination, and loose connections.

- Fluid maintenance: Change hydraulic fluid and filters according to the manufacturer’s recommendations.

- Component testing: Test hydraulic pumps, valves, and cylinders to identify any potential issues.

- System bleeding: Remove air from the system to ensure proper operation.

- Pressure adjustments: Adjust system pressure to optimal levels based on the vehicle’s load and operating conditions.

10. What are the challenges and opportunities in the heavy vehicle repair industry?

Challenges

- Technological advancements: Keeping up with rapidly evolving vehicle technologies.

- Skilled workforce shortage: Finding and retaining qualified heavy vehicle repair technicians.

- Regulatory compliance: Ensuring compliance with safety and environmental regulations.

- Competition: Facing competition from other repair shops and technology advancements.

Opportunities

- Increased demand: Growing demand for heavy vehicle repair services due to increased vehicle usage.

- Technology integration: Using technology to improve efficiency and diagnostic capabilities.

- Specialization: Opportunities to specialize in specific areas of heavy vehicle repair.

- Training and development: Continuous training and development to enhance skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heavy Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heavy Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Heavy Repairers are responsible for repairing and maintaining heavy machinery and equipment, such as trucks, buses, locomotives, and mining equipment. They use specialized tools and equipment to diagnose and repair a wide variety of mechanical and electrical problems.

1. Troubleshooting and diagnosing mechanical and electrical problems

Heavy Repairers use their knowledge of mechanics and electronics to troubleshoot and diagnose problems with heavy machinery and equipment. They use a variety of tools and equipment, such as multimeters, oscilloscopes, and pressure gauges, to identify the source of the problem.

- Inspect machinery and equipment for defects and damage.

- Use diagnostic tools and equipment to identify the source of problems.

2. Repairing and replacing mechanical and electrical components

Heavy Repairers repair and replace a variety of mechanical and electrical components, such as engines, transmissions, brakes, and electrical wiring. They use specialized tools and equipment to perform these repairs.

- Repair or replace faulty mechanical and electrical components.

- Reassemble machinery and equipment after repairs.

3. Maintaining and servicing machinery and equipment

Heavy Repairers perform regular maintenance and service on heavy machinery and equipment to keep it in good working condition. They perform tasks such as changing oil, filters, and spark plugs, and lubricating moving parts.

- Perform regular maintenance and service on machinery and equipment.

- Inspect machinery and equipment for potential problems.

4. Working with other technicians and mechanics

Heavy Repairers often work with other technicians and mechanics to repair and maintain heavy machinery and equipment. They must be able to communicate effectively with others and work as part of a team.

- Collaborate with other technicians and mechanics to repair and maintain machinery and equipment.

- Share knowledge and expertise with other team members.

Interview Tips

In order to ace your interview, it is important to be prepared. Here are a few tips to help you get ready:

1. Research the company and the position

Take some time to research the company you are interviewing with and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and it will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website and read about their mission, values, and history.

- Check out the company’s social media pages to see what employees are saying about the company.

- Read reviews of the company on Glassdoor and other job search websites.

2. Practice answering common interview questions

There are certain questions that interviewers ask almost every candidate, such as “Tell me about yourself” and “Why are you interested in this position?” Take some time to practice answering these questions so that you can deliver your responses confidently and concisely.

- Use the STAR method to answer behavioral questions.

- Prepare a brief elevator pitch about yourself.

- Practice answering questions about your skills, experience, and goals.

3. Dress professionally and arrive on time

First impressions matter, so make sure you dress professionally and arrive on time for your interview. This will show the interviewer that you are respectful of their time and that you are serious about the position.

- Wear a suit or business casual attire.

- Be well-groomed and make sure your clothes are clean and pressed.

- Arrive at the interview location at least 15 minutes early.

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic about the position and who are positive about their ability to do the job. Show the interviewer that you are excited about the opportunity and that you are confident in your skills and abilities.

- Smile and make eye contact with the interviewer.

- Be energetic and enthusiastic in your responses.

- Express your confidence in your ability to do the job.

5. Follow up after the interview

After the interview, send a thank-you note to the interviewer. This is a great way to reiterate your interest in the position and to show your appreciation for the interviewer’s time.

- Send a thank-you note within 24 hours of the interview.

- In the note, thank the interviewer for their time and reiterate your interest in the position.

- Follow up with the interviewer if you don’t hear back within a week or two.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Heavy Repairer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.