Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Clutch Specialist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

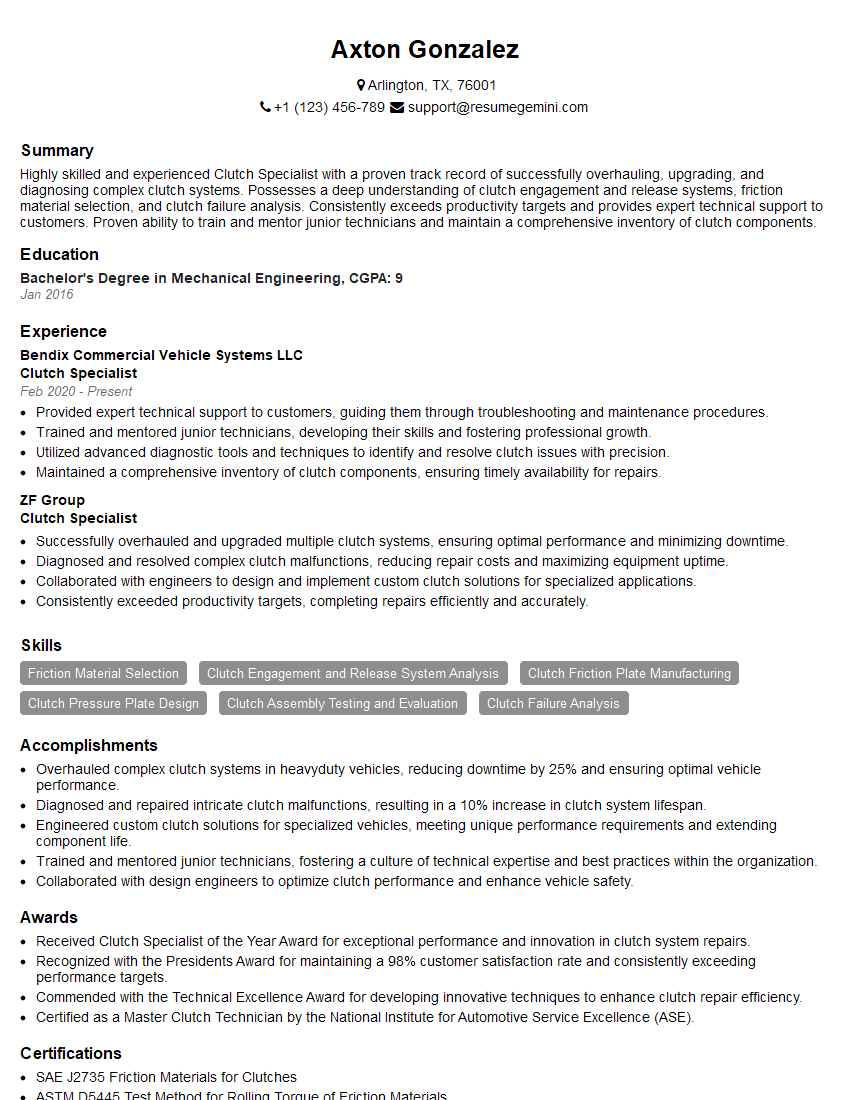

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clutch Specialist

1. Describe the different types of clutches and their applications?

- Mechanical Clutches: These are the most common type of clutch and use friction to engage and disengage the engine and transmission.

- Hydraulic Clutches: These use hydraulic pressure to engage and disengage the clutch, which can be more precise and smoother than mechanical clutches.

- Centrifugal Clutches: These use centrifugal force to engage the clutch when the engine reaches a certain speed, which is often used in small engines.

- Electromagnetic Clutches: These use an electromagnet to engage and disengage the clutch, which can be very fast and precise.

2. What are the common causes of clutch failure?

Causes Related to the Clutch Disc

- Wear and tear due to friction during engagement and disengagement

- Contamination by oil or grease, reducing friction and causing slippage

- Overheating due to excessive slipping or towing heavy loads

Causes Related to the Pressure Plate

- Warping or cracking due to high temperatures or excessive force

- Worn or damaged diaphragm springs, reducing clamping force

- Loose or damaged bolts, causing misalignment and uneven wear

3. How do you diagnose and troubleshoot clutch problems?

- Visual Inspection: Check for signs of wear, damage, or contamination on the clutch disc, pressure plate, and release bearing.

- Test Drive: Drive the vehicle and observe symptoms such as slipping, shuddering, or difficulty engaging gears.

- Clutch Pedal Feel: Assess the pedal’s resistance, travel, and engagement point.

- Hydraulic System Check: Inspect the master and slave cylinders, hoses, and lines for leaks or restrictions.

4. What are the steps involved in replacing a clutch?

- Safety Precautions: Park the vehicle on a level surface, engage the parking brake, and disconnect the battery.

- Removal: Remove the transmission, flywheel, and clutch components.

- Inspection: Inspect the flywheel, pressure plate, release bearing, and other related parts for wear or damage.

- Installation: Install the new clutch components, ensuring proper alignment and torque specifications.

- Reassembly: Reinstall the transmission and other components, including the driveshaft and exhaust system.

- Adjustment: Adjust the clutch pedal free play and hydraulic system (if applicable) according to manufacturer’s specifications.

- Testing: Test drive the vehicle to verify proper clutch operation and address any remaining issues.

5. What are the different types of clutch fluids and their applications?

- Mineral-Based Fluids: These are petroleum-based fluids commonly used in older vehicles with manual transmissions.

- Synthetic Fluids: These are man-made fluids that offer better performance, higher temperature resistance, and longer service intervals.

- Semi-Synthetic Fluids: These are a blend of mineral and synthetic fluids, providing a balance of performance and affordability.

- DOT 3, DOT 4, and DOT 5 Fluids: These are brake fluids that meet specific Department of Transportation (DOT) standards and can be used in hydraulic clutch systems.

6. How do you maintain and service a clutch system?

- Regular Inspections: Check the clutch fluid level, pedal free play, and for any signs of leaks or damage.

- Fluid Changes: Replace the clutch fluid according to the manufacturer’s recommended intervals to maintain its properties and prevent corrosion.

- Clutch Adjustment: Adjust the clutch pedal free play as needed to ensure proper engagement and disengagement.

- Lubrication: Lubricate the clutch release bearing and linkage points to reduce friction and wear.

- Avoid Overheating: Avoid excessive slipping or towing heavy loads that can overheat the clutch.

7. What are the safety precautions to consider when working on a clutch system?

- Park on a Level Surface: Engage the parking brake to prevent the vehicle from rolling.

- Disconnect the Battery: Remove the negative terminal to prevent electrical shocks.

- Use Proper Tools: Ensure you have the correct tools for the job, including a torque wrench for proper tightening.

- Wear Safety Gear: Wear gloves and safety glasses to protect yourself from sharp edges and fluids.

- Support the Transmission: Use a transmission jack or support to safely lower and raise the transmission during removal and installation.

8. What are the latest advancements in clutch technology?

- Dual-Mass Flywheels: These flywheels reduce torsional vibrations, improving drivability and clutch life.

- Self-Adjusting Clutches: These clutches automatically adjust the pedal free play, reducing maintenance requirements.

- Ceramic and Carbon Fiber Clutch Discs: These materials offer higher friction and heat resistance, suitable for high-performance applications.

- Electronic Clutch Control: Advanced systems use sensors and actuators to optimize clutch engagement and disengagement, enhancing performance and fuel economy.

- Electro-Hydraulic Clutches: These clutches combine electric and hydraulic actuation, providing precise and responsive clutch control.

9. How do you stay up-to-date with the latest trends and developments in clutch technology?

- Attend Industry Events: Participate in trade shows, conferences, and workshops to learn about new technologies and innovations.

- Read Technical Publications: Subscribe to industry magazines, journals, and online forums to stay informed about the latest research and advancements.

- Manufacturer Training: Enroll in training programs offered by clutch manufacturers to gain hands-on experience and knowledge about their latest products.

- Online Resources: Utilize online databases, technical articles, and webinars to access up-to-date information and best practices.

- Networking with Experts: Connect with other clutch specialists, engineers, and industry professionals to share knowledge and stay abreast of emerging trends.

10. What is your favorite type of clutch and why?

- Multi-Plate Clutch: I prefer multi-plate clutches for their ability to handle high torque loads and provide smooth engagement due to the increased surface area.

- Ceramic Clutch: Ceramic clutches offer exceptional durability, heat resistance, and friction, making them ideal for high-performance applications where traditional clutches may struggle.

- Electro-Hydraulic Clutch: Electro-hydraulic clutches provide precise and responsive control, enabling advanced features such as launch control and hill-hold assist.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clutch Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clutch Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Clutch Specialist performs a wide range of tasks essential for smooth and efficient vehicle operation. Key responsibilities include:

1. Clutch Maintenance and Repair

Inspect and diagnose clutch systems to identify any issues or potential problems.

- Disassemble and reassemble clutches.

- Replace worn or damaged clutch components, such as discs, plates, and bearings.

- Adjust clutch settings for optimal performance.

2. Troubleshooting and Diagnosis

Resolve clutch-related issues by analyzing symptoms and conducting thorough inspections.

- Identify and diagnose worn or slipping clutches.

- Troubleshoot clutch chattering, shuddering, or other operational problems.

- Determine the cause of clutch failure and recommend appropriate repair or replacement options.

3. Installation and Replacement

Install or replace complete clutch assemblies or individual components as needed.

- Ensure proper fit and alignment of clutch components.

- Adjust and fine-tune the clutch system for optimal performance.

- Inspect and test new or repaired clutch systems to verify functionality.

4. Preventive Maintenance

Conduct regular inspections and maintenance to prevent clutch issues and prolong service life.

- Lubricate and clean clutch components.

- Check clutch fluid levels and condition.

- Provide recommendations for clutch maintenance schedules based on vehicle usage and operating conditions.

Interview Preparation Tips

To ace your Clutch Specialist interview, follow these tips:

1. Research the Company and Industry

Learn about the company’s culture, values, and recent developments. Research industry trends and advancements in clutch technology.

- Visit the company website and LinkedIn page.

- Read industry publications and attend trade shows.

- Keep up-to-date on the latest clutch materials and designs.

2. Practice Your Technical Skills

Review clutch operation, troubleshooting, and repair techniques. Familiarize yourself with different types of clutches and their applications.

- Solve mock troubleshooting scenarios.

- Practice diagnosing and repairing common clutch problems.

- Stay updated on industry best practices and safety regulations.

3. Highlight Your Experience

Emphasize your hands-on experience in clutch maintenance and repair. Quantify your accomplishments and use specific examples to demonstrate your skills.

- Describe times you successfully diagnosed and repaired complex clutch issues.

- Mention any certifications or training programs you have completed.

- Provide references from previous employers who can attest to your abilities.

4. Prepare for Common Interview Questions

Anticipate standard interview questions and prepare thoughtful responses:

- Tell me about your experience diagnosing and repairing clutch systems.

- Describe your approach to preventive clutch maintenance.

- How would you troubleshoot a slipping clutch?

- What are the latest advancements in clutch technology?

- Why are you interested in working for our company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Clutch Specialist interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!