Feeling lost in a sea of interview questions? Landed that dream interview for Fuel Retrofitting Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Fuel Retrofitting Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

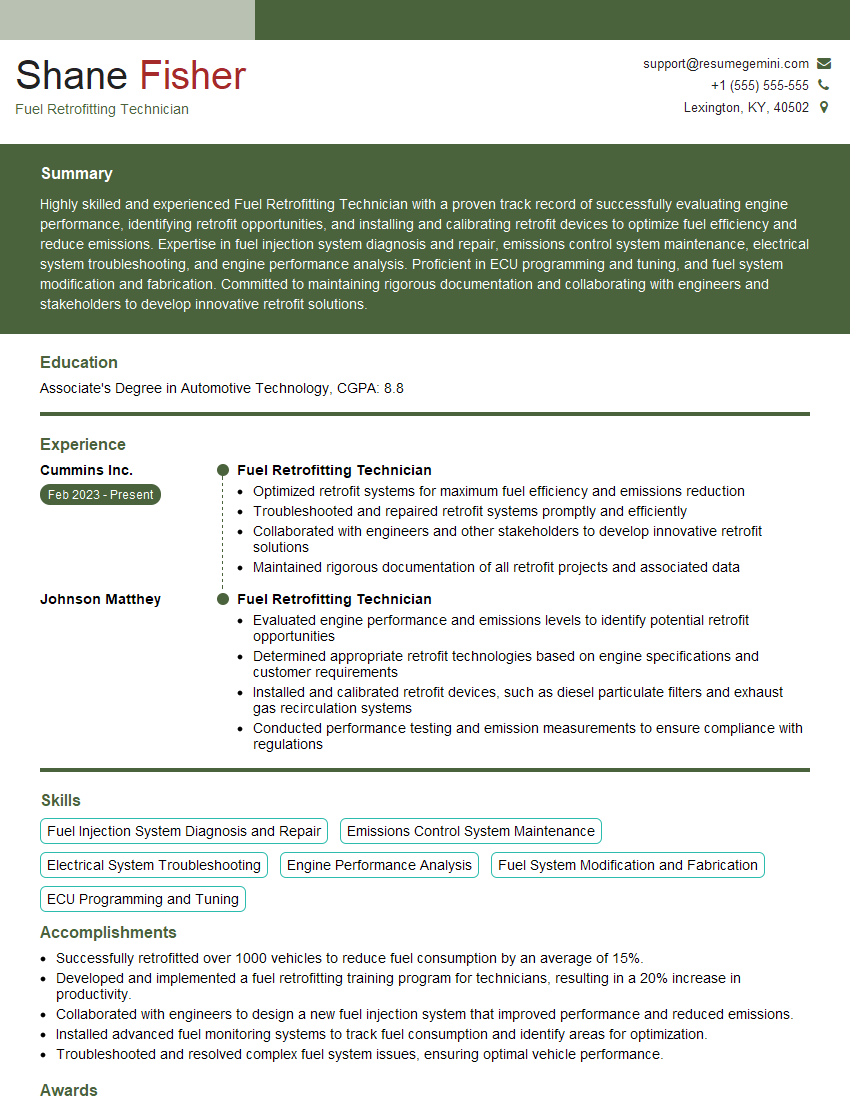

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fuel Retrofitting Technician

1. Explain the steps involved in performing a fuel system retrofit on a vehicle?

The steps involved in performing a fuel system retrofit on a vehicle:

- Assess the vehicle’s compatibility: Determine if the vehicle is suitable for a fuel system retrofit by considering factors such as engine type, fuel tank capacity, and emission standards.

- Gather necessary components: Acquire the required components for the retrofit, including fuel tanks, fuel lines, fuel pumps, and engine management systems.

- Remove the original fuel system: Disconnect and remove the existing fuel tank, fuel lines, and fuel pump.

- Install the new fuel system: Mount the new fuel tank, connect the fuel lines, and install the new fuel pump.

- Configure the engine management system: Program the engine management system to recognize and manage the new fuel system.

- Test and inspect: Conduct thorough testing and inspections to ensure the retrofitted fuel system is functioning properly and meets safety and performance standards.

2. What are the different types of fuel systems used in vehicles and their characteristics?

Internal Combustion Engines

- Gasoline Direct Injection (GDI): Fuel is directly injected into the combustion chamber

- Port Fuel Injection (PFI): Fuel is injected into the intake manifold

- Carburetor: Fuel is mixed with air before entering the engine

Alternative Fuel Systems

- Liquefied Petroleum Gas (LPG): Butane or propane is stored in a liquid state

- Compressed Natural Gas (CNG): Natural gas is stored in a compressed state

- Biodiesel: Renewable fuel derived from plant oils or animal fats

3. Describe the safety precautions that need to be taken when working on a fuel system?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and coveralls.

- Work in a well-ventilated area to avoid exposure to fuel vapors.

- Disconnect the battery to prevent electrical hazards.

- Relieve fuel system pressure before working on any components.

- Use proper tools and equipment, and follow manufacturer’s instructions.

- Handle fuel with care to prevent spills or leaks.

- Have a fire extinguisher readily available.

4. What are the common challenges encountered during fuel system retrofits and how do you overcome them?

- Vehicle Compatibility: Ensure compatibility by thoroughly researching and selecting appropriate components.

- Fuel System Integration: Properly configure and integrate the new fuel system with the engine management system.

- Emission Compliance: Comply with emission standards by selecting low-emission components and optimizing engine performance.

- Fuel Quality: Use high-quality fuel and address fuel compatibility issues.

- Safety Concerns: Prioritize safety by following proper procedures and using the correct tools and equipment.

5. Explain the importance of fuel system maintenance and how it can extend the life of a vehicle?

- Prevent Clogging: Regular maintenance prevents fuel lines and filters from clogging, ensuring efficient fuel flow.

- Optimize Combustion: Clean fuel injectors and spark plugs optimize combustion, improving engine performance and fuel economy.

- Reduce Emissions: Well-maintained fuel systems reduce harmful emissions by ensuring proper fuel-air mixture.

- Extend Component Life: Regular maintenance extends the lifespan of fuel pumps, fuel tanks, and other components.

- Improve Vehicle Reliability: Properly maintained fuel systems contribute to the overall reliability and longevity of the vehicle.

6. What diagnostic tools and techniques do you use to diagnose and troubleshoot fuel system problems?

- Fuel Pressure Gauge: Measures fuel pressure in the system.

- Fuel Injector Tester: Checks the performance of fuel injectors.

- Scanner: Reads engine data and diagnostic codes related to the fuel system.

- Visual Inspection: Examines fuel lines, filters, and components for leaks or damage.

- Test Drive: Monitors vehicle performance and identifies any issues under real-world conditions.

7. Explain the environmental benefits and cost savings associated with fuel system retrofits?

Environmental Benefits

- Reduced emissions: Less harmful pollutants released into the atmosphere.

- Improved air quality: Cleaner air for healthier communities.

Cost Savings

- Lower fuel consumption: More efficient fuel systems lead to increased mileage.

- Extended vehicle life: Well-maintained fuel systems contribute to overall vehicle longevity.

- Government incentives: Some regions offer incentives for fuel system retrofits.

8. Discuss the future trends and advancements in fuel system technology?

- Electrification: Transition to electric vehicles reduces reliance on fossil fuels.

- Hydrogen Fuel Cells: Clean and renewable energy source with zero emissions.

- Advanced Injection Systems: Improved atomization and combustion for increased efficiency.

- Artificial Intelligence (AI): Predictive maintenance and diagnostics.

- Sustainability: Use of biofuels and renewable materials.

9. Stay updated with the latest technologies and best practices in fuel system retrofitting?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Participate in online forums and discussions.

- Seek training and certification from manufacturers and professional organizations.

- Network with other professionals in the field.

10. Why are you interested in this fuel system retrofitting technician position?

- Passion for automotive technology and alternative fuel systems.

- Desire to contribute to environmental sustainability.

- Strong mechanical aptitude and problem-solving abilities.

- Enthusiasm for learning and staying updated with industry advancements.

- Commitment to providing exceptional customer service.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fuel Retrofitting Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fuel Retrofitting Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fuel Retrofitting Technicians are responsible for modifying existing vehicles to run on alternative fuels, such as propane or natural gas. Their duties include:

1. Vehicle Assessment

Inspect vehicles to determine the feasibility of fuel retrofitting

2. Fuel System Modifications

Install and modify fuel tanks, fuel lines, and fuel injectors

3. Electrical System Modifications

Install and modify electrical components, such as ignition systems and fuel pumps

4. Emissions Testing

Conduct emissions testing to ensure compliance with environmental regulations

5. Customer Education

Educate customers on the benefits and operation of alternative fuel vehicles

Interview Tips

To ace the interview for a Fuel Retrofitting Technician position, consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s operations and the alternative fuel industry

2. Highlight Relevant Experience

Emphasize your skills in vehicle modifications, fuel systems, and emissions testing

3. Prepare for Technical Questions

Expect questions about fuel retrofitting techniques, emissions regulations, and safety protocols

4. Showcase Your Commitment to Sustainability

Express your passion for reducing emissions and promoting environmentally friendly vehicles

5. Practice Your Communication Skills

Clearly explain your technical knowledge and ability to communicate with customers

6. Be Enthusiastic and Professional

Demonstrate your enthusiasm for the role and maintain a professional demeanor throughout the interview

7. Prepare Questions for the Interviewer

Asking thoughtful questions shows your interest in the position and the company

8. Dress Appropriately

Wear professional attire that reflects the technical nature of the role

9. Follow Up

Thank the interviewer for their time and express your continued interest in the position

Next Step:

Now that you’re armed with the knowledge of Fuel Retrofitting Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Fuel Retrofitting Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini