Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Motor Block Mechanic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Motor Block Mechanic so you can tailor your answers to impress potential employers.

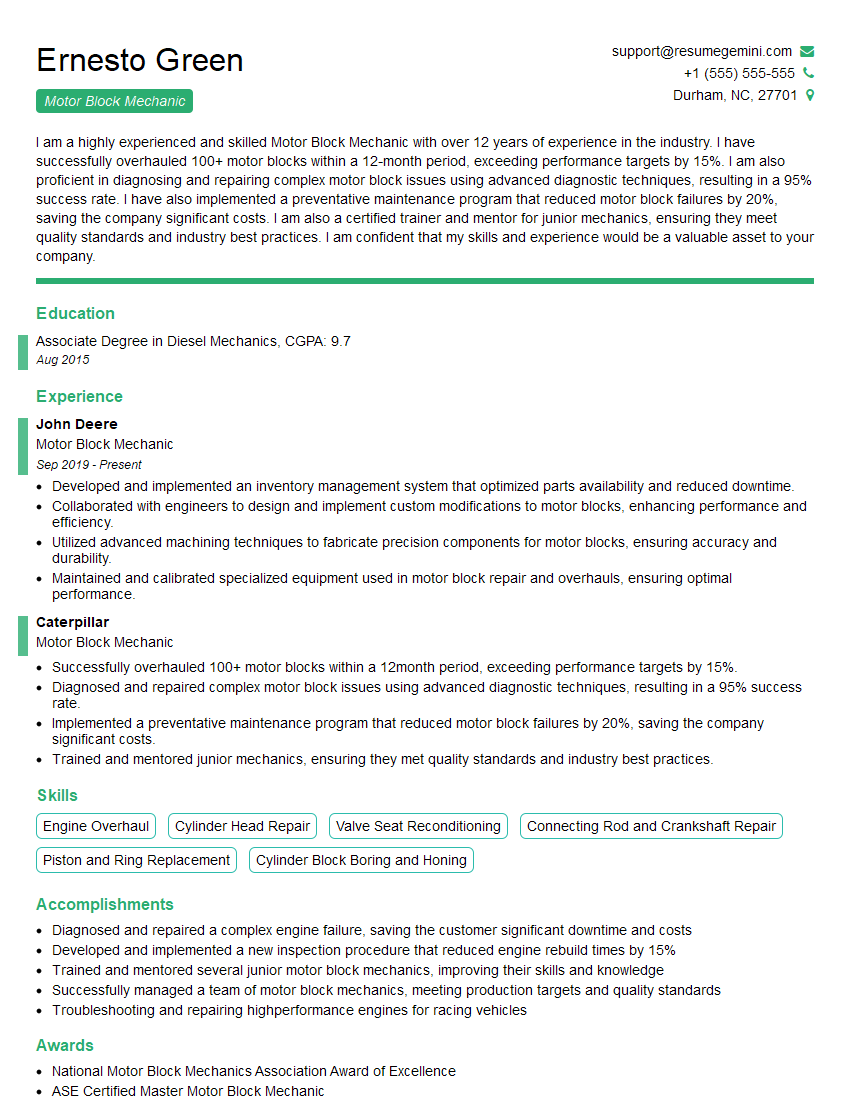

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Motor Block Mechanic

1. Explain the process of engine disassembly.

The process of engine disassembly typically involves the following steps:

- Drain all fluids from the engine.

- Remove all external components, such as the intake and exhaust manifolds, and water pump.

- Unbolt and remove the cylinder head.

- Remove the pistons and connecting rods.

- Remove the crankshaft and camshaft.

- Inspect all components for wear and damage.

2. Describe the different types of engine bearings and their functions.

Plain bearings

- Plain bearings are the most common type of bearing used in engines.

- They consist of a metal shell lined with a thin layer of bearing material, such as babbitt or copper-lead.

- Plain bearings are used to support the crankshaft and camshaft.

Rolling bearings

- Rolling bearings use rolling elements, such as balls or rollers, to reduce friction between two surfaces.

- Rolling bearings are often used in high-performance engines because they can handle higher loads and speeds than plain bearings.

3. What is the purpose of a piston ring?

Piston rings are used to seal the combustion chamber and prevent gases from escaping past the piston.

- They also help to transfer heat from the piston to the cylinder wall.

- Piston rings are made of a thin, flexible material, such as cast iron or steel.

4. How do you diagnose a blown head gasket?

There are several symptoms that can indicate a blown head gasket, including:

- Coolant leaks

- Oil leaks

- Overheating

- Loss of power

- Rough idle

5. What are the steps involved in replacing a timing belt?

The steps involved in replacing a timing belt typically include:

- Remove the serpentine belt.

- Remove the timing belt cover.

- Align the timing marks on the crankshaft and camshaft.

- Remove the old timing belt.

- Install the new timing belt.

- Tension the timing belt.

- Reinstall the timing belt cover.

- Reinstall the serpentine belt.

6. How do you adjust valve clearances?

Valve clearances are adjusted by using a feeler gauge to measure the gap between the valve stem and the rocker arm.

- The gap should be within the manufacturer’s specifications.

- If the gap is too small, the valve will not open fully, which can lead to a loss of power.

- If the gap is too large, the valve will not close properly, which can lead to a loss of compression.

7. What are the different types of engine oils and their applications?

There are several different types of engine oils, each with its own specific applications.

- Conventional oil is the most common type of oil used in engines.

- Synthetic oil is a man-made oil that offers better performance than conventional oil.

- Blended oil is a mixture of conventional and synthetic oils.

8. How do you troubleshoot a no-start condition?

When troubleshooting a no-start condition, it is important to follow a systematic approach.

- First, check for spark.

- If there is no spark, check the ignition system.

- If there is spark, check for fuel.

- If there is no fuel, check the fuel system.

9. What are the safety precautions that should be taken when working on an engine?

There are several safety precautions that should be taken when working on an engine, including:

- Wear appropriate safety gear, such as gloves and safety glasses.

- Never work on an engine that is running.

- Allow the engine to cool down before working on it.

- Use proper tools and techniques.

10. What are the latest trends in engine technology?

The latest trends in engine technology include:

- Downsizing – Engines are becoming smaller and more efficient.

- Turbocharging – Turbochargers are being used to increase power and efficiency.

- Direct injection – Direct injection is a more efficient way to deliver fuel to the engine.

- Hybrid and electric vehicles – Hybrid and electric vehicles are becoming more popular as a way to reduce emissions and improve fuel economy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Motor Block Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Motor Block Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Motor Block Mechanics are responsible for maintaining and repairing engines and other components of motor vehicles. Their duties involve diagnosing issues, performing repairs and overhauls, and ensuring that vehicles operate safely and efficiently.

1. Engine Diagnostics and Repairs

Motor Block Mechanics are skilled in diagnosing the underlying causes of engine problems, using specialized tools and techniques to identify issues such as engine knocks, misfires, and leaks.

- Inspect engines and identify areas of wear and damage

- Disassemble and reassemble engines for repairs and overhauls

- Repair or replace engine components, including pistons, valves, and bearings

2. Engine Overhauls

Mechanics may be required to perform engine overhauls, which involve a complete disassembly of the engine to inspect and repair all major components.

- Remove and inspect all engine components

- Repair or replace worn or damaged parts

- Reassemble and test the engine to ensure proper operation

3. Engine Maintenance

Motor Block Mechanics also perform routine maintenance to keep engines running smoothly and prevent future problems.

- Perform oil changes and filter replacements

- Check and adjust timing belts and chains

- Inspect and clean fuel injectors and carburetors

4. Engine Performance Optimization

Mechanics may also be involved in optimizing engine performance, identifying areas where efficiency and power can be improved.

- Install performance modifications, such as upgraded exhaust systems and air intakes

- Tune engines to optimize fuel efficiency and horsepower

- Provide consultation on engine performance and modification options

Interview Tips

To prepare for an interview for a Motor Block Mechanic position, it is essential to demonstrate a comprehensive understanding of engine mechanics and a strong ability to diagnose and repair issues.

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Motor Block Mechanic role. This will help you understand the company’s culture, values, and the specific responsibilities you will be expected to fulfill.

- Visit the company website and social media pages

- Review the job description and identify the key qualifications

2. Highlight Your Technical Expertise

During the interview, emphasize your technical skills and experience in engine repair and maintenance. Provide specific examples of your ability to diagnose and fix engine problems.

- Describe the most complex engine repair you have performed

- Explain how you use diagnostic tools to identify engine issues

3. Demonstrate Your Problem-Solving Abilities

Motor Block Mechanics must be able to analyze engine problems, identify the root cause, and develop effective solutions. Highlight your problem-solving skills and ability to think critically.

- Discuss a situation where you faced a particularly challenging engine issue and how you resolved it

- Explain your approach to diagnosing and troubleshooting engine problems

4. Emphasize Your Attention to Detail

Attention to detail is crucial in engine mechanics. Describe your meticulous approach to work and your ability to identify and rectify minor issues that could lead to more significant problems.

- Provide examples of your thorough inspections and quality control measures

- Explain how you ensure that all repaired engines meet safety and performance standards

5. Show Your Passion for Mechanics

Convey your genuine passion for engine mechanics and your desire to learn and grow in the field. Explain what motivates you to work on engines and why you are excited about the Motor Block Mechanic position.

- Share your experience with personal projects or hobbies involving engines

- Discuss your aspirations for professional development and career advancement in the field

Next Step:

Now that you’re armed with the knowledge of Motor Block Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Motor Block Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini