Feeling lost in a sea of interview questions? Landed that dream interview for Wheel Aligner but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wheel Aligner interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

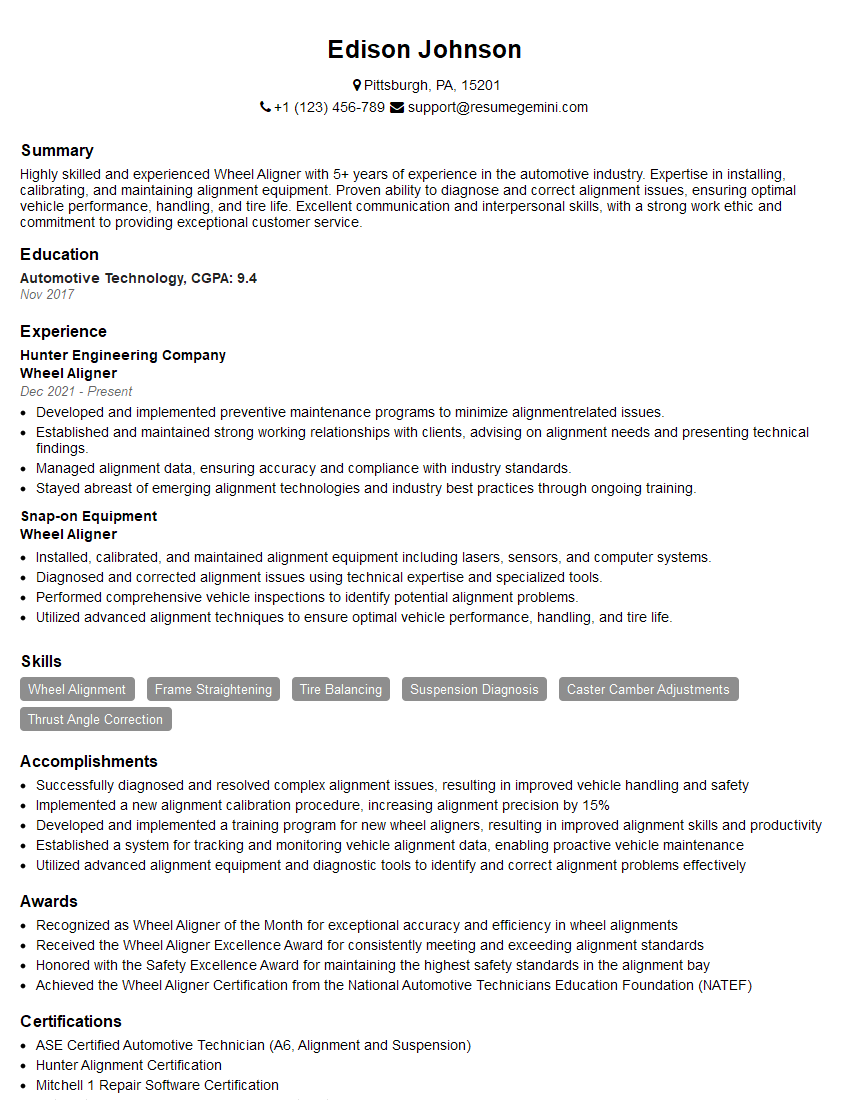

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wheel Aligner

1. What are the primary responsibilities of a Wheel Aligner?

The primary responsibilities of a Wheel Aligner include:

- Inspecting and measuring wheel alignment using specialized equipment.

- Adjusting and realigning wheels according to manufacturer specifications and customer requirements.

- Diagnosing and repairing suspension problems that affect wheel alignment.

- Installing and replacing tires, wheels, and other suspension components.

- Maintaining a clean and organized work area.

2. What equipment do you use for wheel alignment?

Types of Wheel Alignment Equipment

- Alignment Machine

- Alignment Sensors

- Wheel Clamps

- Turntables

- Measuring Tapes

Using Wheel Alignment Equipment

- Position the vehicle on the alignment machine.

- Attach the sensors to the wheels.

- Run the alignment program and follow the instructions.

- Make the necessary adjustments to the wheel alignment.

- Verify the results and provide a print-out of the alignment report to the customer.

3. What are the different types of wheel alignment and when are they used?

The different types of wheel alignment and when they are used include:

- Toe alignment: Adjusts the angle of the wheels as they point forward, ensuring that they are parallel to each other and perpendicular to the ground. Used to prevent uneven tire wear and improve handling.

- Camber alignment: Adjusts the angle of the wheels as they tilt inward or outward from the vehicle, ensuring that they are perpendicular to the ground. Used to prevent uneven tire wear and improve cornering stability.

- Caster alignment: Adjusts the angle of the steering axis as it turns, affecting the vehicle’s stability and return-to-center capabilities. Used to improve steering response and reduce tire wear.

4. What are the causes and effects of improper wheel alignment?

Causes of Improper Wheel Alignment

- Hitting curbs or potholes

- Uneven wear on tires

- Vehicle damage during an accident

- Improper tire inflation

Effects of Improper Wheel Alignment

- Uneven tire wear leading to premature replacement

- Reduced fuel efficiency

- Steering problems, including difficulty in maintaining a straight line

- Increased risk of suspension damage

5. What are some common suspension problems that affect wheel alignment?

Common suspension problems that affect wheel alignment include:

- Worn or damaged ball joints

- Bent or broken tie rods

- Loose or damaged control arms

- Worn or damaged springs

- Improper ride height

6. How do you troubleshoot and resolve wheel alignment issues?

To troubleshoot and resolve wheel alignment issues, the following steps can be taken:

- Gather customer information: Discuss symptoms, driving habits, and any recent repairs or modifications.

- Inspect the vehicle: Check for any visible damage, uneven tire wear, or suspension problems.

- Perform a wheel alignment inspection: Use alignment equipment to measure toe, camber, and caster angles.

- Analyze the alignment results: Determine which angles are out of specification and identify the potential causes.

- Make adjustments: Use alignment tools to adjust the wheel angles according to manufacturer specifications.

- Re-inspect the alignment: Verify that the adjustments have corrected the alignment issues.

- Provide a print-out of the alignment report: Explain the results to the customer and recommend any necessary repairs.

7. What are the safety precautions that must be taken when working on wheel alignment?

The following safety precautions must be taken when working on wheel alignment:

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Use proper lifting equipment and support stands to lift and stabilize the vehicle.

- Follow manufacturer’s instructions for the specific alignment equipment being used.

- Keep the work area clean and free of debris.

- Be aware of potential hazards, such as sharp edges or hot surfaces.

8. What are the latest advancements in wheel alignment technology?

The latest advancements in wheel alignment technology include:

- 3D Alignment Systems: Use multiple sensors to create a three-dimensional representation of the vehicle, providing more accurate and comprehensive alignment measurements.

- Wireless Alignment Systems: Allow technicians to move around the vehicle freely during the alignment process, eliminating the need for cables and reducing potential hazards.

- Automated Alignment Systems: Use computer-controlled arms and sensors to perform alignment adjustments automatically, saving time and improving accuracy.

9. How do you stay up-to-date on the latest wheel alignment techniques and best practices?

To stay up-to-date on the latest wheel alignment techniques and best practices, the following methods can be used:

- Attend industry seminars and workshops.

- Read trade publications and technical articles.

- Participate in online forums and discussion groups.

- Receive training from manufacturers and equipment suppliers.

- Get certified through recognized organizations.

10. What qualities and skills make for a successful Wheel Aligner?

Successful Wheel Aligners typically possess the following qualities and skills:

- Excellent technical skills and knowledge of wheel alignment principles.

- Strong mechanical aptitude and ability to diagnose and repair suspension problems.

- Attention to detail and ability to follow manufacturer specifications precisely.

- Customer service skills and ability to explain alignment results and recommendations to customers.

- Physical stamina and ability to work in a physically demanding environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wheel Aligner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wheel Aligner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wheel Aligners are responsible for ensuring that wheels are properly aligned to the vehicle’s suspension system. They use specialized equipment to measure and adjust the angles of the wheels, ensuring optimal performance and handling.

1. Wheel Alignment and Adjustments

Wheel Aligners perform precise wheel alignments by utilizing advanced equipment to measure and adjust camber, caster, and toe angles to manufacturer specifications.

- Measuring and analyzing wheel angles using alignment machines

- Adjusting wheel alignment to meet manufacturer specifications

2. Tire Inspections and Repairs

Wheel Aligners inspect tires for tread depth, wear patterns, and damage. They also perform repairs, such as plugging and patching, to maintain optimal tire performance.

- Inspecting tires for tread depth, wear patterns, and damage

- Performing tire repairs, including plugging, patching, and balancing

3. Suspension System Checks

Wheel Aligners assess the condition of suspension components, including ball joints, tie rods, and control arms. They identify potential issues and make recommendations for repairs or replacements.

- Inspecting suspension components for wear and damage

- Diagnosing and identifying suspension problems

- Making recommendations for repairs or replacements

4. Customer Service and Communication

Wheel Aligners interact with customers, explaining the importance of wheel alignment and tire maintenance. They provide clear explanations of services performed and answer any questions or concerns.

- Communicating with customers about wheel alignment and tire maintenance

- Explaining the importance of proper wheel alignment and tire condition

- Providing excellent customer service

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some effective tips to help you ace your Wheel Aligner interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and industry reputation. Thoroughly review the job description to understand the specific responsibilities and qualifications required for the role.

- Visit the company’s website and social media pages

- Read industry-related articles and news

- Prepare thoughtful questions about the company and position

2. Highlight Relevant Skills and Experience

Emphasize your technical skills and experience in wheel alignment and tire maintenance. Quantify your accomplishments whenever possible, using specific metrics and results to demonstrate your impact.

- Highlight your proficiency in using alignment machines and diagnostic equipment

- Showcase your ability to analyze suspension systems and identify issues

- Provide examples of your successful customer interactions

3. Demonstrate a Commitment to Safety

Safety is paramount in the automotive industry. Emphasize your adherence to safety protocols and your understanding of the potential hazards associated with vehicle maintenance.

- Explain your experience with safety procedures

- Discuss your knowledge of hazardous materials and proper handling techniques

- Highlight your commitment to maintaining a clean and organized work area

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare your responses accordingly. Practice answering questions about your experience, skills, and motivations. Consider the following examples:

- “Tell us about your experience using wheel alignment equipment.”

- “Describe a challenging suspension issue you have diagnosed and resolved.”

- “How do you prioritize customer service in your work?”

5. Be Enthusiastic and Professional

Show your enthusiasm for the role and the industry. Maintain a positive and professional demeanor throughout the interview. Dress appropriately, arrive on time, and be respectful of the interviewer’s time.

- Smile and make eye contact

- Listen attentively to the interviewer’s questions

- Thank the interviewer for their time and consideration

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wheel Aligner interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.