Are you gearing up for an interview for a Wheel Alignment Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wheel Alignment Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

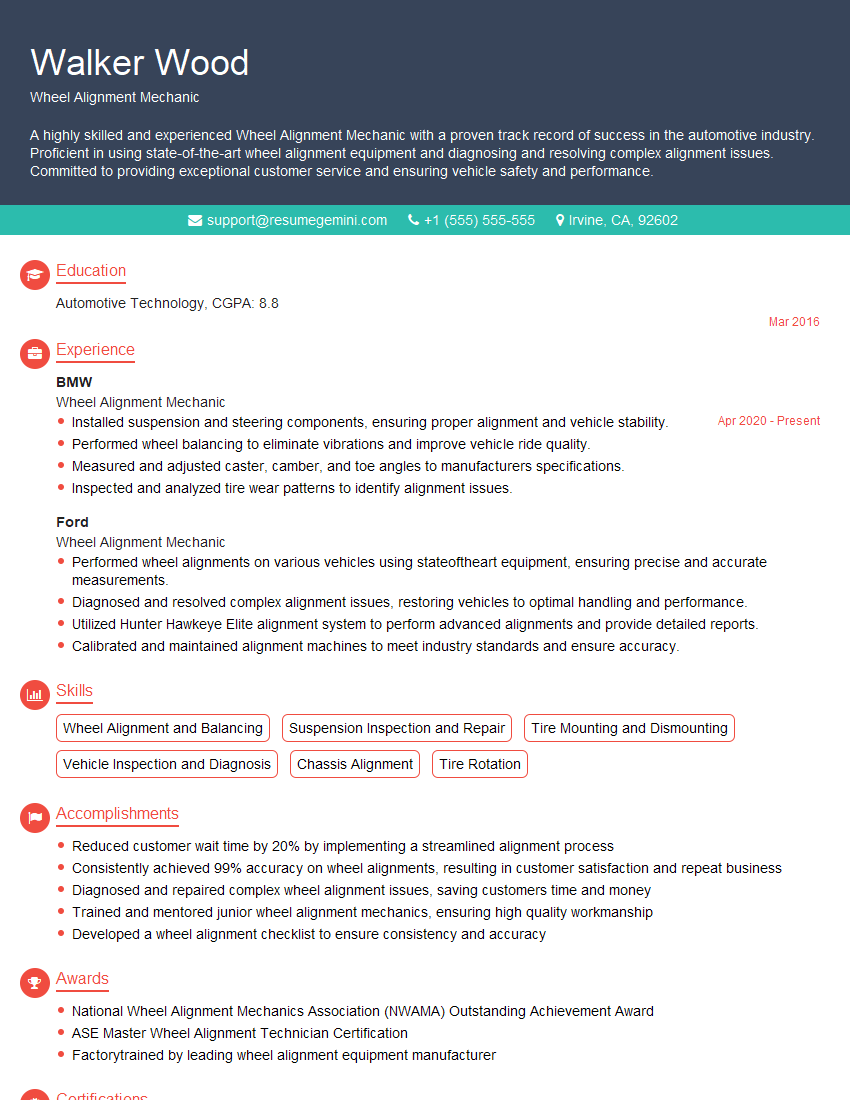

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wheel Alignment Mechanic

1. Explain the steps involved in performing a wheel alignment?

Sample Answer:

- Inspect the vehicle’s tires for any signs of uneven wear or damage.

- Check the vehicle’s suspension components for any signs of damage or wear.

- Mount the vehicle on a lift and attach the wheel alignment machine.

- Calibrate the wheel alignment machine and select the appropriate vehicle specifications.

- Measure the vehicle’s camber, caster, and toe angles.

- Compare the measured angles to the vehicle’s specifications and make adjustments as necessary.

- Road test the vehicle to verify that the alignment is correct.

2. What are the different types of wheel alignment machines?

Sample Answer:

CCD Wheel Alignment Machines

- Highly accurate and precise, using cameras to capture images of reflective targets placed on the wheels.

- Can measure camber, caster, toe, and other angles with high accuracy.

Laser Wheel Alignment Machines

- Use lasers to project beams onto the wheels and measure the angles between the beams.

- Less accurate than CCD machines but more affordable and easier to use.

Mechanical Wheel Alignment Machines

- Use mechanical gauges and scales to measure wheel angles.

- Less precise than CCD or laser machines but still reliable for basic alignment checks.

3. What are the most common causes of wheel misalignment?

Sample Answer:

- Hitting potholes or curbs

- Suspension damage

- Uneven tire wear

- Incorrect tire inflation

- Vehicle overloading

- Improper wheel alignment during previous service

4. What are the signs and symptoms of wheel misalignment?

Sample Answer:

- Uneven tire wear

- Vehicle pulling to one side while driving

- Steering wheel not centered when driving straight

- Increased fuel consumption

- Reduced tire life

- Vibration in the steering wheel or vehicle

5. What are the consequences of driving with misaligned wheels?

Sample Answer:

- Premature tire wear

- Reduced fuel efficiency

- Poor handling and stability

- Increased risk of accidents

- Damage to suspension components

6. What tools and equipment do you use for wheel alignment?

Sample Answer:

- Wheel alignment machine

- Measuring tapes

- Levels

- Protractors

- Alignment clamps

- Hydraulic lifts

- Socket wrenches

- Torque wrenches

7. How do you adjust camber, caster, and toe angles?

Sample Answer:

Camber Adjustment

- Adjusting the upper and lower control arms

- Using camber bolts or shims

Caster Adjustment

- Adjusting the upper control arm

- Using caster shims or bushings

Toe Adjustment

- Adjusting the tie rods

- Using toe clamps or shims

8. What are the different types of tire wear patterns and what do they indicate?

Sample Answer:

- Inside edge wear: Indicates excessive negative camber or toe-out.

- Outside edge wear: Indicates excessive positive camber or toe-in.

- Center edge wear: Indicates overinflation or incorrect toe setting.

- Heel and toe wear: Indicates incorrect camber and toe settings.

- Feathering: Indicates a misalignment condition that causes the tire to scrub against the road surface.

- Cupping: Indicates suspension problems or uneven tire wear.

9. How do you diagnose and repair suspension problems that affect wheel alignment?

Sample Answer:

- Inspect suspension components for damage or wear, including ball joints, tie rods, control arms, and bushings.

- Check for loose or worn suspension bolts and nuts.

- Use a pry bar or lever to check for play in suspension joints.

- Measure suspension angles and compare them to specifications.

- Replace or repair damaged or worn suspension components as necessary.

10. What are the latest technologies and trends in wheel alignment?

Sample Answer:

- 3D Wheel Alignment Systems: Use advanced sensors and cameras to measure wheel angles with high precision and accuracy.

- ADAS Calibration: Wheel alignments are becoming increasingly important for vehicles equipped with Advanced Driver Assistance Systems (ADAS), such as lane departure warning and adaptive cruise control.

- Wheel Alignment Diagnostics: Diagnostic tools and software can help identify and resolve wheel alignment issues more efficiently.

- Remote Wheel Alignment: Some wheel alignment machines now offer remote access and support, allowing technicians to diagnose and adjust alignments remotely.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wheel Alignment Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wheel Alignment Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wheel Alignment Mechanic plays a crucial role in ensuring the safety and optimal performance of vehicles by specializing in the alignment of wheels. Their primary responsibilities include:

1. Wheel Alignment Inspections

Inspecting and analyzing vehicle wheel alignments using specialized equipment such as alignment machines to assess if they meet manufacturer specifications and industry standards.

2. Wheel Adjustments and Repairs

Adjusting and repairing wheel angles, such as camber, caster, and toe, to restore proper alignment and optimize tire performance, handling, and fuel efficiency.

3. Tire Maintenance and Repair

Mounting, balancing, and rotating tires to ensure even wear and prevent premature tire failure. Repairing punctures and performing tire patching as needed.

4. Suspension System Maintenance

Inspecting and maintaining vehicle suspension systems, including shock absorbers, struts, and springs. Identifying and repairing worn or damaged components to ensure proper alignment and handling.

5. Customer Service and Communication

Providing excellent customer service by explaining alignment procedures and addressing vehicle concerns. Effectively communicating with customers and keeping them informed about the work performed.

Interview Tips

To ace an interview for a Wheel Alignment Mechanic position, it’s crucial to prepare effectively. Here are some tips and hacks:

1. Research and Familiarize Yourself

Thoroughly research the company and the role you’re applying for. Visit their website, read industry articles, and gain insights into their alignment services and approach.

2. Practice Common Interview Questions

Prepare for typical interview questions by practicing your answers. Anticipate questions about your experience in wheel alignment, tire repair, and customer service.

3. Showcase Your Technical Expertise

Highlight your knowledge of wheel alignment principles, suspension systems, and tire maintenance techniques. Use specific examples and technical terms to demonstrate your proficiency.

4. Emphasize Problem-Solving Skills

Share examples of your ability to diagnose and resolve alignment issues. Explain how you troubleshoot complex problems and find innovative solutions to ensure optimal vehicle performance.

5. Highlight Your Safety Focus

Emphasize your commitment to safety and your understanding of industry regulations and guidelines. Explain how you prioritize the safety of customers and vehicles during alignment procedures.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wheel Alignment Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wheel Alignment Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.