Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Farm Implement Engine Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

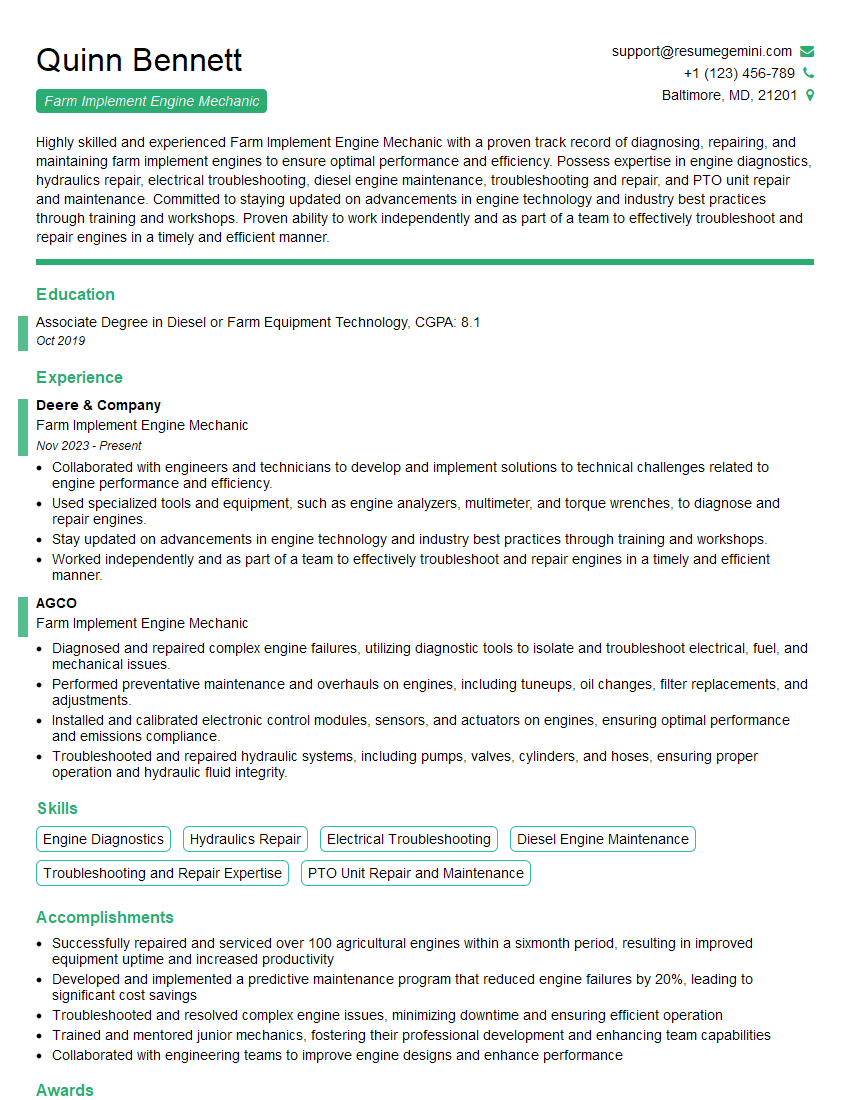

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Farm Implement Engine Mechanic

1. Describe the steps involved in troubleshooting a farm implement engine that is not starting.

- Check for fuel and air supply

- Inspect the spark plugs

- Test the battery and starter

- Check for loose or damaged wires

- Perform a diagnostic test

2. How do you diagnose and repair a hydraulic leak in a farm implement?

Troubleshooting

- Inspect the hoses and fittings for leaks

- Check the hydraulic cylinders for damage

- Test the hydraulic pump and valves

Repair

- Replace damaged hoses or fittings

- Repair or replace hydraulic cylinders

- Overhaul hydraulic pump or valves

3. What are the best practices for maintaining and servicing farm implement engines?

- Regular oil changes and filter replacements

- Inspecting and cleaning air filters

- Checking and replacing spark plugs

- Lubricating moving parts

- Performing diagnostic tests

4. How do you ensure that farm implements are operating safely and efficiently?

- Inspecting implements before each use

- Maintaining proper tire pressure

- Using guards and shields

- Wearing appropriate safety gear

- Training operators on safe operation

5. What are the common types of farm implement engines and their key features?

- Diesel engines: high torque, fuel efficiency

- Gasoline engines: lightweight, easy to start

- LPG engines: clean burning, low emissions

- Electric engines: quiet, zero emissions

6. How do you calculate the horsepower requirements of a farm implement?

- Determine the width of the implement

- Estimate the working speed

- Consider the soil conditions

- Use a formula to calculate horsepower

7. What are the safety precautions to take when working with farm implement engines?

- Wear appropriate safety gear

- Keep hands away from moving parts

- Disconnect the battery before working on the engine

- Avoid working on hot engines

- Use proper lifting techniques

8. Describe the different types of fuel systems used in farm implement engines.

- Carburetor systems: mix air and fuel

- Fuel injection systems: inject fuel directly into the combustion chamber

- Common rail systems: use a high-pressure fuel rail to deliver fuel

9. How do you identify and troubleshoot electrical problems in farm implement engines?

- Inspect wiring for damage

- Test fuses and circuit breakers

- Check battery terminals

- Use a multimeter to diagnose electrical faults

10. What are the latest trends and advancements in farm implement engine technology?

- Variable valve timing

- Electronic fuel injection

- Turbocharging

- Diesel particulate filters

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Farm Implement Engine Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Farm Implement Engine Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Farm Implement Engine Mechanics play a crucial role in ensuring the efficient functioning of agricultural machinery. To execute this task, their key responsibilities include:

1. Diagnosing and Troubleshooting Engine Issues

Identifying and resolving engine malfunctions by conducting thorough inspections, utilizing diagnostic tools, and analyzing engine performance data.

- Testing and evaluating engine components, such as cylinders, pistons, valves, and injectors.

- Interpreting diagnostic data from sensors, gauges, and computer systems.

2. Repairing and Overhauling Engines

Performing necessary repairs and overhauls to restore engine functionality and optimize performance.

- Replacing worn or damaged parts, such as pistons, bearings, and gaskets.

- Honing cylinders, resurfacing heads, and rebuilding engines.

3. Maintaining and Inspecting Engines

Conducting regular maintenance and inspections to ensure optimal engine operation and prevent breakdowns.

- Changing oil and filters, adjusting valves, and cleaning engine components.

- Inspecting engines for signs of wear, leaks, or damage.

4. Troubleshooting and Repairing Electrical Systems

Diagnosing and resolving electrical issues in engine systems, including wiring, sensors, and control modules.

- Testing electrical circuits for continuity, resistance, and voltage.

- Replacing faulty electrical components and repairing wiring.

Interview Tips

Preparing thoroughly for an interview is essential for leaving a lasting impression and increasing your chances of success.

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and the specific responsibilities of the Farm Implement Engine Mechanic position.

- Visit the company’s website and social media pages.

- Review the job description carefully and identify the key skills and qualifications.

2. Practice Answering Common Interview Questions

Prepare thoughtful responses to common interview questions related to your skills, experience, and career goals. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

- Describe a time when you successfully diagnosed and repaired a complex engine issue.

- Explain how you prioritize tasks and manage your time effectively in a fast-paced work environment.

3. Highlight Your Relevant Skills and Experience

Emphasize your technical skills, such as engine diagnostics, repair, and maintenance. Quantify your accomplishments whenever possible to demonstrate your impact.

- Mention any certifications or training you have that are relevant to the position.

- Share examples of projects or assignments where you applied your skills.

4. Be Enthusiastic and Professional

Convey your passion for engines and your commitment to providing exceptional service. Be polite, respectful, and maintain a positive attitude throughout the interview.

- Dress professionally and arrive on time.

- Thank the interviewer for their time and follow up promptly.

Next Step:

Now that you’re armed with the knowledge of Farm Implement Engine Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Farm Implement Engine Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini