Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cement Tester Assistant interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cement Tester Assistant so you can tailor your answers to impress potential employers.

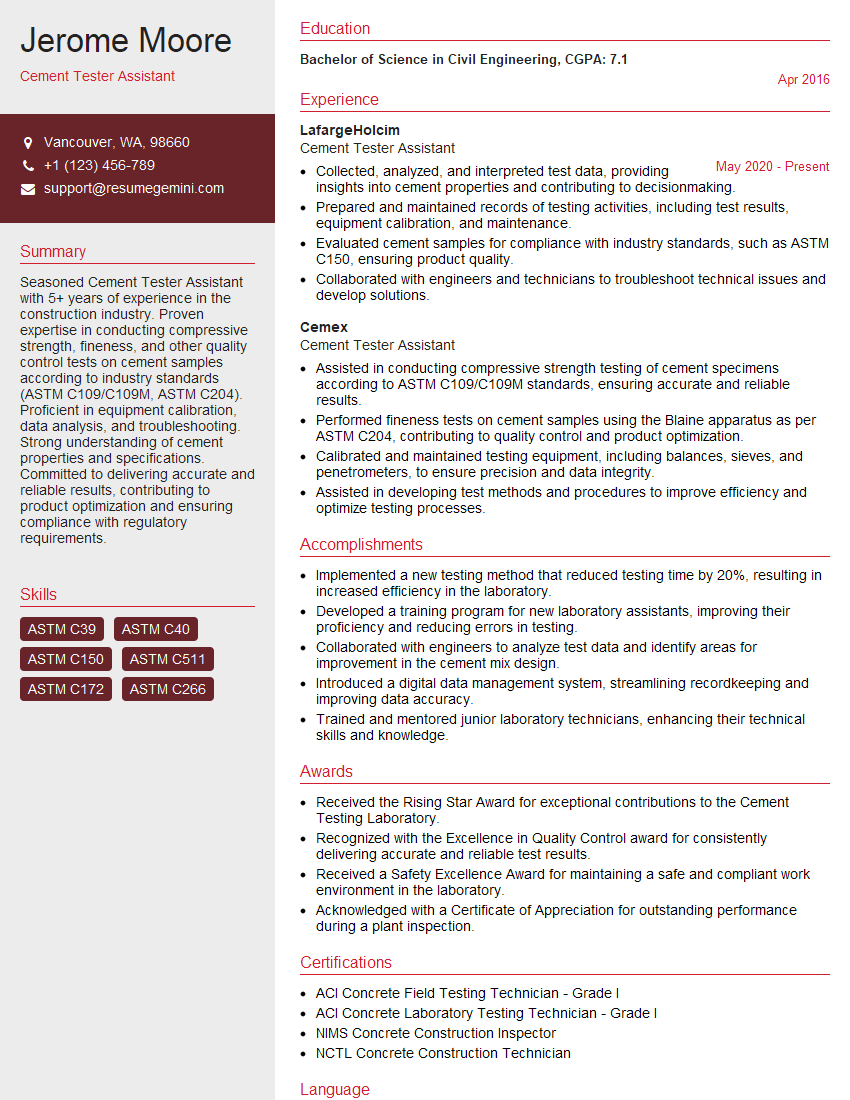

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cement Tester Assistant

1. What is the purpose of the soundness test for cement?

Soundness tests are conducted to assess the stability of the cement, particularly its ability to retain its strength after exposure to various environmental conditions, including moisture, alternate freezing and thawing cycles, or sulphate attack. These tests help ensure the cement’s durability and longevity in concrete structures, preventing potential structural failures or deterioration over time.

2. Describe the procedure for conducting a compressive strength test on cement.

Preparing the Cement Paste:

- Weigh and mix the cement and water in a predetermined ratio (usually 1:3, cement:water) to create a uniform paste.

Molding the Test Specimens:

- Pour the cement paste into standard-sized cylindrical molds and tamp it down to remove any air pockets.

- Smooth the surface of the paste and mark the specimens for identification.

Curing the Specimens:

- Place the molded specimens in a controlled environment with high humidity and a specified temperature, typically for 24 hours.

- After 24 hours, remove the specimens from the molds and immerse them in water for up to 28 days to allow for hydration and strength development.

Testing the Specimens:

- After the curing period, remove the specimens from the water and break them using a compression testing machine.

- Record the maximum load applied before failure and calculate the compressive strength based on the applied load and the cross-sectional area of the specimens.

3. What are the different types of cements and their applications?

- Portland Cement: General-purpose cement used in a wide range of construction applications, from residential buildings to infrastructure projects.

- Blended Cements: Mixtures of Portland cement with other materials, such as fly ash, slag, or limestone, offering specific properties like improved durability or reduced heat generation.

- White Cement: Used in decorative applications where aesthetics are important, such as architectural facades or sculptures.

- Rapid-Hardening Cement: Formulated to gain strength quickly, allowing for faster construction schedules.

- Masonry Cement: Specifically designed for mortar and masonry applications, providing good workability and adhesion.

4. Explain the role of calcium oxide and silica in cement production.

- Calcium Oxide (CaO): A major component of cement, which reacts with water during hydration to form calcium hydroxide and calcium silicate hydrates, the primary strength-giving compounds.

- Silica (SiO2): Also a crucial ingredient, reacting with calcium oxide to form calcium silicates, which contribute to the cement’s strength and durability.

5. What are the quality control measures implemented in a cement manufacturing plant?

- Raw Material Inspection: Testing of incoming raw materials, such as limestone, clay, and sand, to ensure they meet specified quality standards.

- Process Control: Monitoring and adjusting process parameters throughout production, such as feed rates, kiln temperature, and grinding time.

- Product Testing: Conducting various tests on finished cement, including compressive strength, soundness, and setting time, to comply with industry standards and customer requirements.

- Equipment Calibration: Regular calibration of testing equipment, such as compression testing machines and sieves, to ensure accurate and reliable results.

- Traceability System: Maintaining records of production and testing data to trace and identify batches of cement for quality control purposes.

6. How do you maintain laboratory equipment used in cement testing?

- Regular Cleaning: Keep all equipment clean of cement dust and debris to prevent contamination and ensure proper operation.

- Proper Storage: Store equipment in designated areas with controlled temperature and humidity to maintain accuracy and prevent damage.

- Scheduled Calibration: Follow recommended calibration schedules to ensure equipment is operating within specified tolerances and providing reliable results.

- Preventive Maintenance: Conduct regular inspections and perform minor repairs or adjustments to prevent major breakdowns and ensure optimal performance.

- User Training: Train laboratory personnel on proper equipment use, maintenance, and calibration procedures to minimize human error and maintain equipment longevity.

7. What safety precautions should be taken when working in a cement testing laboratory?

- Respiratory Protection: Wear a dust mask or respirator to avoid inhaling cement dust.

- Protective Clothing: Wear gloves, safety glasses, and appropriate clothing to minimize exposure to cement, which can be irritating to skin and eyes.

- Adequate Ventilation: Ensure the laboratory is well-ventilated to prevent dust accumulation and maintain a safe working environment.

- Proper Handling: Handle heavy equipment, such as compression testing machines, with care to prevent injuries.

- First Aid: Be familiar with first aid procedures in case of contact with cement or any other hazardous materials.

8. How do you interpret the results of cement tests and report them accurately?

- Test Result Analysis: Carefully examine the test results and compare them to established standards or specifications.

- Reporting: Generate clear and concise reports that include all relevant test data, such as sample identification, test method used, and the obtained results.

- Uncertainty Estimation: Consider the uncertainty associated with the test results and express them within appropriate limits.

- Professional Interpretation: If necessary, provide professional interpretation of the results and offer recommendations based on your expertise.

- Confidentiality: Maintain the confidentiality of test results and client information as per established protocols.

9. Describe the importance of maintaining accurate records in cement testing.

- Quality Assurance: Accurate records provide evidence of the quality of the cement tested and support the reliability of the results.

- Traceability: Records help trace the history of the cement, including its source, production date, and test results, in case of any future inquiries or investigations.

- Legal Compliance: Maintaining proper records meets regulatory requirements and demonstrates compliance with industry standards and certifications.

- Continuous Improvement: Records allow for trend analysis and identification of areas for improvement in the testing process.

- Customer Satisfaction: Accurate records instil confidence in customers by assuring them of the reliability and transparency of the testing results.

10. How do you stay up-to-date with the latest advancements in cement testing technologies and standards?

- Continuing Education: Attend conferences, workshops, and seminars to learn about new testing methods and technologies.

- Professional Organizations: Join professional organizations related to cement testing, such as the American Society for Testing and Materials (ASTM), to access technical publications and networking opportunities.

- Industry Publications: Subscribe to industry magazines, journals, and newsletters to stay informed about the latest research and developments.

- Collaboration with Experts: Consult with other cement testing professionals, researchers, and manufacturers to exchange knowledge and best practices.

- Equipment Updates: Regularly review new equipment offerings and upgrades to improve efficiency and accuracy in the laboratory.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cement Tester Assistant.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cement Tester Assistant‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The primary responsibilities of a Cement Tester Assistant include:

1. Sample Preparation and Testing

Preparing and conditioning cement samples for testing.

- Weighing, mixing, and molding cement specimens.

- Curing and storing samples under controlled conditions.

2. Test Execution and Data Recording

Performing various tests on cement samples, including:

- Compressive strength tests.

- Setting time tests.

- Physical properties, such as density, soundness, and fineness.

3. Data Analysis and Reporting

Analyzing test results, identifying trends, and interpreting data.

- Preparing reports summarizing test findings.

- Communicating results to supervisors, engineers, and quality control personnel.

4. Equipment Maintenance and Calibration

Maintaining and calibrating testing equipment.

- Inspecting equipment for proper operation.

- Cleaning and adjusting equipment as needed.

Interview Tips

Preparing thoroughly for an interview for a Cement Tester Assistant position is essential to demonstrate your knowledge and skills. Here are some tips to help you ace the interview:

1. Highlight Relevant Experience

Emphasize your experience in sample preparation, testing, and data analysis. Mention any specific techniques or equipment you have used that are relevant to cement testing.

- Example: “In my previous role, I was responsible for preparing and testing cement samples for compressive strength, setting time, and fineness.”

- Example: “I have experience using Vicat apparatus for setting time determination and a compression testing machine for strength evaluation.”

2. Quantify Your Skills

Provide specific examples of your accomplishments and quantify your results whenever possible.

- Example: “I improved the efficiency of cement sample preparation by optimizing the mixing process, reducing preparation time by 15%.”

- Example: “My analysis of test results contributed to identifying a deviation in cement quality, leading to corrective actions and improved product performance.”

3. Showcase Your Technical Knowledge

Demonstrate your understanding of cement testing principles, methods, and standards.

- Example: “I am familiar with ASTM C109, C191, and C311 standards for compressive strength, setting time, and physical property testing of cement.”

- Example: “I have a good understanding of the factors that affect cement hydration and strength development.”

4. Prepare for Behavioral Questions

Behavioral questions focus on your work habits and how you handle specific situations. Practice answering common questions using the STAR method (Situation, Task, Action, Result).

- Example: “Tell me about a time you made a mistake during testing.” (Use the STAR method to describe the situation, what you did, and the outcome.)

- Example: “How do you handle working in a fast-paced and demanding environment?” (Emphasize your ability to prioritize, manage time, and meet deadlines.)

5. Ask Informed Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. It also gives you an opportunity to clarify any aspects of the job or company.

- Example: “I noticed that the company places a strong emphasis on quality control. Can you elaborate on the quality assurance processes followed in your cement manufacturing division?”

- Example: “What are the current challenges and opportunities in cement testing and analysis?”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cement Tester Assistant role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.