Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Industrial Truck Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

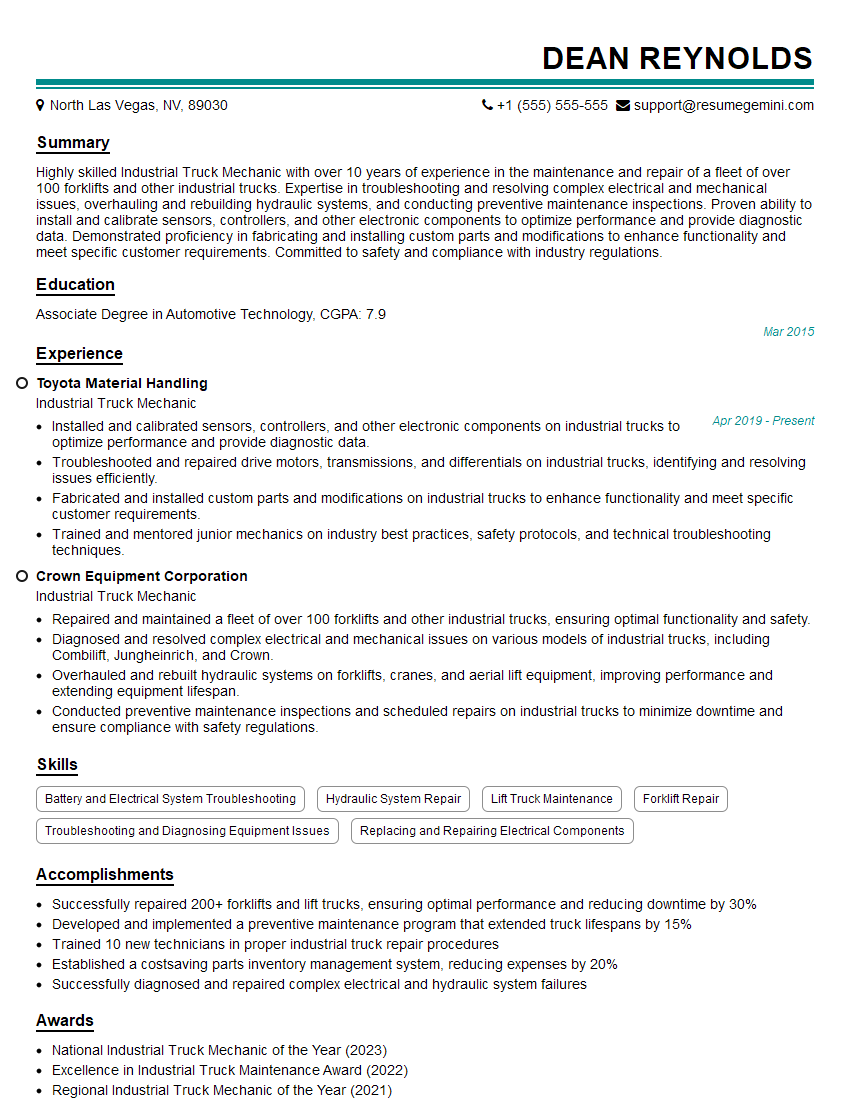

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Truck Mechanic

1. How do you troubleshoot an industrial truck that is not starting?

Troubleshooting an industrial truck involves identifying the cause of the fault and taking corrective actions. Here are some steps I would take:

- Check the battery voltage using a multimeter

- Check the battery cables and connections for corrosion or loose connections

- Check the starter motor for any signs of damage or wear

- If the starter motor is not engaging, check the ignition switch and wiring

- Inspect the fuel system for any leaks or blockages

- Check the air filter for any signs of clogging

2. What are the different types of hydraulic systems used in industrial trucks?

Open hydraulic systems:

- Fluid is stored in a reservoir

- Uses a pump to circulate fluid through the system

- Commonly used in smaller trucks

Closed hydraulic systems:

- Fluid is contained within a pressurized circuit

- Uses a pump and accumulator to maintain system pressure

- Provides better efficiency and control than open systems

3. How do you adjust the brakes on an industrial truck?

To adjust the brakes on an industrial truck, follow these steps:

- Park the truck on a level surface

- Engage the parking brake

- Locate the brake adjustment nuts on the brake drums or calipers

- Tighten the adjustment nuts evenly until you feel slight resistance when spinning the wheel

- Test the brakes by driving the truck slowly and applying the brakes

- Repeat the adjustments as necessary until the brakes are operating properly

4. What are the common causes of overheating in industrial trucks?

Overheating in industrial trucks can be caused by several factors, including:

- High ambient temperatures

- Prolonged periods of heavy operation

- Blockages in the cooling system

- Low coolant levels

- Faulty cooling fan or water pump

- Engine timing issues

5. What are the safety precautions that should be taken when working on industrial trucks?

When working on industrial trucks, it is crucial to prioritize safety. Here are some essential precautions:

- Always wear appropriate personal protective equipment

- Ensure the truck is parked on a level surface and the parking brake is engaged

- Disconnect the battery before performing electrical work

- Use proper lifting equipment when handling heavy components

- Never work under a lifted truck without proper support

- Be aware of your surroundings and potential hazards

6. How do you maintain the battery of an electric industrial truck?

Maintaining the battery of an electric industrial truck is crucial for ensuring optimal performance and longevity.

- Regularly check the battery water levels and top up if necessary

- Clean the battery terminals and connections to prevent corrosion

- Charge the battery fully after each use

- Do not overcharge the battery

- Replace the battery when it reaches the end of its life

7. What are the different types of masts used on industrial trucks?

Masts on industrial trucks are available in several types:

- Single-stage mast: Provides a fixed lifting height

- Two-stage mast: Offers extended lifting heights compared to single-stage masts

- Three-stage mast: Provides even greater lifting heights, suitable for high-stacking applications

- Quad-stage mast: Delivers maximum lifting heights, ideal for warehouses with high ceilings

- Telescopic mast: Offers extended reach capabilities for loading and unloading trucks

8. How do you troubleshoot a hydraulic cylinder that is leaking?

Troubleshooting a leaking hydraulic cylinder involves identifying the source of the leak and taking appropriate actions:

- Check the cylinder seals for damage or wear

- Inspect the cylinder rod for any scratches or nicks

- Check the hydraulic hoses and fittings for any damage or leaks

- Tighten any loose fittings or connections

- If the leak persists, the cylinder may need to be replaced

9. What are the different types of tires used on industrial trucks?

Industrial trucks use various types of tires depending on the application and operating environment:

- Pneumatic tires: Provide cushioning and stability on rough surfaces

- Solid pneumatic tires: Offer durability and puncture resistance

- Cushion tires: Suitable for indoor operations and provide a smooth ride

- Polyurethane tires: Non-marking and ideal for sensitive flooring

- Rubber tires: Provide good traction and stability

10. How do you test the performance of an industrial truck’s traction motor?

Testing the performance of an industrial truck’s traction motor involves several steps:

- Measure the motor’s voltage and current output

- Check the motor’s speed using a tachometer

- Perform a load test by applying a known load to the motor and measuring its performance

- Compare the test results to the manufacturer’s specifications to assess if the motor is functioning properly

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Truck Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Truck Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial Truck Mechanics are responsible for maintaining and repairing a variety of industrial trucks, including forklifts, pallet jacks, and cherry pickers. They ensure that these vehicles are in good working order to prevent accidents or breakdowns. Some of their key responsibilities include:

1. Inspecting and Diagnosing Problems

Industrial Truck Mechanics inspect industrial trucks regularly to identify any potential problems. They look for signs of wear and tear, leaks, or other damage. If they find any issues, they diagnose the problem and determine the best course of action.

- Identifying and diagnosing mechanical, electrical, and hydraulic system problems

- Interpreting diagnostic codes and using diagnostic tools to troubleshoot issues

2. Repairing and Replacing Components

Industrial Truck Mechanics repair or replace components on industrial trucks as needed. They may replace worn-out parts, fix leaks, or rebuild engines. They also perform preventive maintenance tasks, such as changing oil and filters, to keep the trucks running smoothly.

- Replacing batteries, starters, alternators, and other electrical components

- Repairing hydraulic cylinders, hoses, and pumps

3. Testing and Adjusting Systems

Industrial Truck Mechanics test and adjust the systems on industrial trucks to ensure that they are operating properly. They may test the brakes, steering, and hydraulics to make sure that they are working correctly. They also adjust the trucks’ settings to optimize performance.

- Testing and calibrating hydraulic and electrical systems

- Adjusting brakes, steering, and other mechanical components

4. Maintaining Records

Industrial Truck Mechanics maintain records of all the work they perform on industrial trucks. This information is used to track the trucks’ maintenance history and to identify any trends that may indicate a need for further repairs or maintenance.

- Documenting repairs, maintenance, and inspections

- Maintaining inventory of parts and supplies

Interview Tips

Preparing for an interview for an Industrial Truck Mechanic position is essential to making a good impression on potential employers. Here are some tips to help you ace your interview:

1. Research the Company and Position

Take some time to learn about the company you’re interviewing with and the specific position you’re applying for. This will help you understand the company’s culture and values, as well as the specific skills and experience they’re looking for in a candidate.

- Visit the company’s website and social media pages

- Read industry news and articles to stay up-to-date on the latest trends

2. Practice Your Answers

Once you’ve done your research, it’s a good idea to practice answering some common interview questions. This will help you feel more confident and prepared during the interview.

- Use the STAR method to answer behavioral questions

- Practice answering questions about your skills, experience, and qualifications

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for an office setting.

- Wear a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and free of wrinkles

4. Be Punctual

Punctuality is important for any job interview, but it’s especially important for an Industrial Truck Mechanic position. This shows the employer that you’re reliable and respectful of their time.

- Plan your route to the interview in advance

- Give yourself plenty of time to get to the interview location

5. Be Yourself

The most important thing is to be yourself during the interview. Employers want to get to know the real you, so don’t try to be someone you’re not. Just be confident, enthusiastic, and prepared, and you’ll be sure to make a good impression.

- Answer questions honestly and directly

- Be yourself and let your personality shine through

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Industrial Truck Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.