Are you gearing up for a career in Oil Field Equipment Mechanic? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Oil Field Equipment Mechanic and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

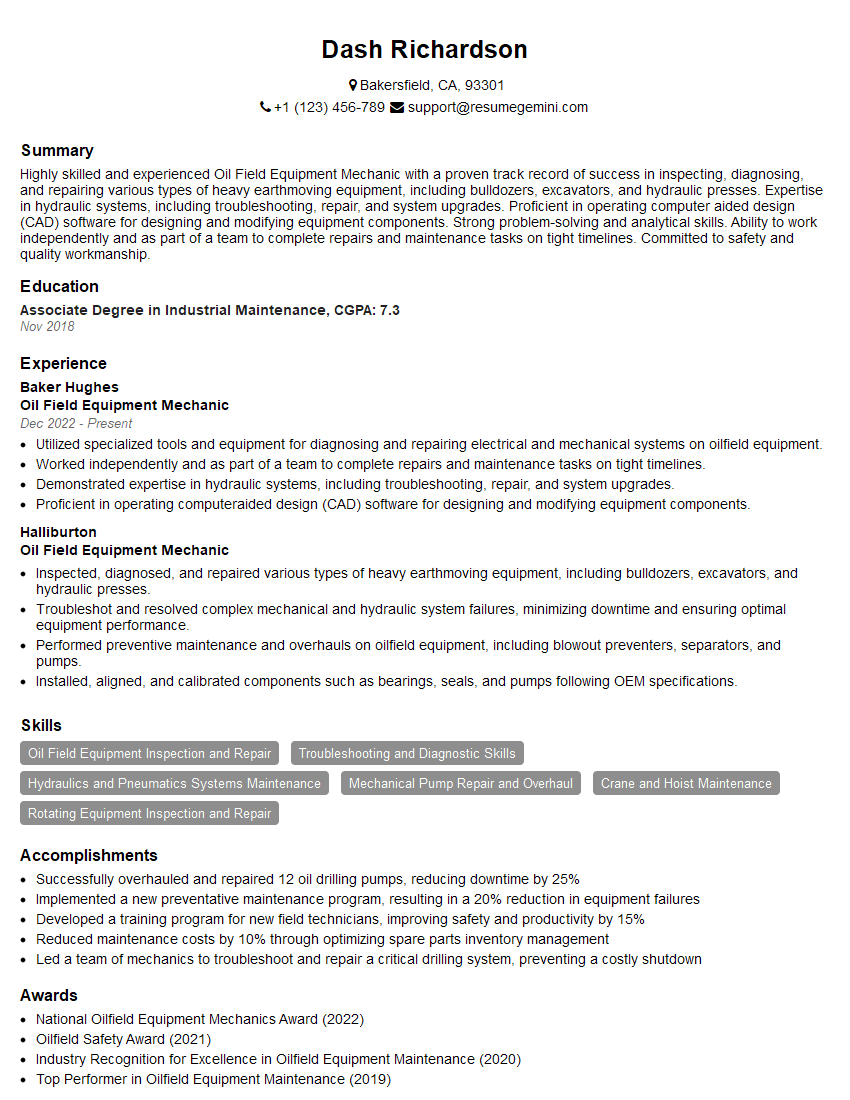

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Field Equipment Mechanic

1. Explain the process of troubleshooting a hydraulic system?

Following are the steps to troubleshoot a hydraulic system:

- Inspect the system for any leaks or visible damage.

- Check the fluid level and condition.

- Test the system pressure using a pressure gauge.

- Listen for any unusual noises or vibrations.

- Use a multimeter to check the electrical continuity of the system.

2. How do you maintain a centrifugal pump?

Daily Maintenance

- Check the oil level and add oil as needed.

- Check the pump for any leaks or damage.

- Listen for any unusual noises or vibrations.

Weekly Maintenance

- Clean the pump and remove any debris.

- Inspect the impeller and diffuser for any wear or damage.

- Check the bearings for any signs of wear or damage.

- Test the pump to ensure that it is operating properly.

Monthly Maintenance

- Replace the oil filter.

- Lubricate the bearings.

- Inspect the pump for any major signs of wear or damage.

- Test the pump to ensure that it is operating properly.

3. What are the different types of valves used in oil field equipment?

- Gate valves: Used to isolate a section of pipe or to control the flow of fluid.

- Globe valves: Used to control the flow of fluid by varying the size of the opening.

- Check valves: Used to prevent backflow of fluid.

- Ball valves: Used to isolate a section of pipe or to control the flow of fluid.

- Butterfly valves: Used to control the flow of fluid by varying the angle of a disc.

- Diaphragm valves: Used to control the flow of fluid by varying the size of an opening.

4. What are the safety precautions that should be taken when working on oil field equipment?

- Wear appropriate personal protective equipment (PPE).

- Be aware of the potential hazards associated with the equipment.

- Follow all safety procedures and guidelines.

- Never work on equipment that is energized.

- Lock out and tag out equipment before performing any maintenance or repairs.

5. What are the common problems that can occur with oil field equipment?

- Leaks

- Clogs

- Corrosion

- Erosion

- Mechanical failures

6. What are the different types of materials that are used in the construction of oil field equipment?

- Steel

- Stainless steel

- Aluminum

- Titanium

- Copper

- Brass

- Plastics

- Composites

7. What are the different types of welding that are used in the oil field?

- Arc welding

- MIG welding

- TIG welding

- Flux-cored arc welding

- Submerged arc welding

8. What are the different types of machining that are used in the oil field?

- Turning

- Milling

- Drilling

- Boring

- Grinding

9. What are the different types of non-destructive testing (NDT) that are used in the oil field?

- Radiography

- Ultrasound

- Magnetic particle inspection

- Dye penetrant testing

- Eddy current testing

10. What are the different types of corrosion that can occur in the oil field?

- Uniform corrosion

- Pitting corrosion

- Crevice corrosion

- Stress corrosion cracking

- Intergranular corrosion

- Galvanic corrosion

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Field Equipment Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Field Equipment Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oil Field Equipment Mechanics play a critical role in maintaining and repairing complex equipment used in the oil and gas industry. Their key responsibilities include:

1. Equipment Maintenance and Repair

Diagnose and troubleshoot malfunctions in oil field equipment, including pumps, motors, generators, and compressors.

- Repair or replace faulty components

- Conduct preventive maintenance to ensure optimal equipment performance

2. Installation and Commissioning

Install and commission new equipment, ensuring proper operation and compliance with industry standards.

- Troubleshoot and resolve any issues during installation

- Provide training to operators on the use and maintenance of the equipment

3. Safety Compliance

Adhere to strict safety protocols and regulations while performing maintenance and repair tasks.

- Identify and mitigate potential hazards

- Wear appropriate personal protective equipment (PPE)

4. Collaboration and Communication

Collaborate with engineers, supervisors, and other team members to ensure effective repair and maintenance operations.

- Communicate repair recommendations and progress updates

- Document maintenance and repair activities

Interview Tips

To ace an interview for an Oil Field Equipment Mechanic position, consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s operations, the oil and gas industry, and recent technological advancements.

- Review the company website and industry publications

- Attend industry events or webinars

2. Highlight Relevant Experience

Emphasize your experience in maintaining and repairing oil field equipment, including specific examples of successful projects.

- Use the STAR method (Situation, Task, Action, Result) to describe your accomplishments

- Quantify your results whenever possible

3. Showcase Safety and Compliance

Stress your commitment to safety and compliance in all work activities.

- Provide examples of safety protocols you have implemented

- Discuss your understanding of industry regulations and standards

4. Practice Troubleshooting Scenarios

Anticipate questions about how you troubleshoot common equipment issues.

- Practice troubleshooting steps and logical reasoning

- Use technical jargon and industry-specific terminology

5. Prepare for Physical Challenges

Be prepared to discuss your physical fitness and ability to work in demanding environmental conditions.

- Describe your physical abilities and any relevant training or experience

- Emphasize your adaptability and willingness to work in challenging environments

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Oil Field Equipment Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!