Are you gearing up for an interview for a Trailer Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Trailer Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

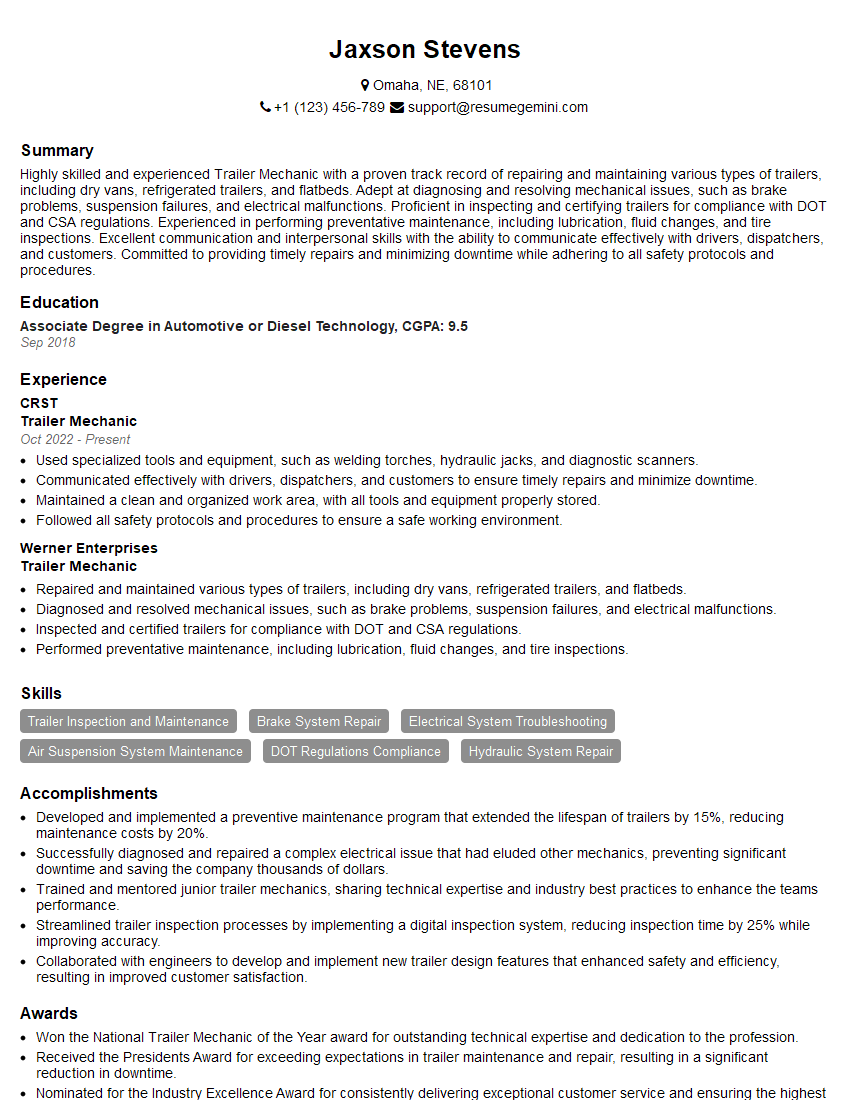

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Trailer Mechanic

1. What is the essential equipment you use to repair trailers?

As a Trailer Mechanic, I utilize a range of tools and equipment to perform repairs effectively. These include:

- Socket wrench set: For tightening and loosening nuts and bolts on various trailer components.

- Wrenches: Including adjustable, crescent, and pipe wrenches, for gripping and tightening various types of fasteners.

- Pry bars: For removing panels, separating components, and applying leverage during repairs.

- Voltmeter and multimeter: For testing electrical circuits, diagnosing faults, and ensuring proper functionality.

2. How do you inspect a trailer’s brakes?

Visual Inspection

- Examine brake pads for wear, cracks, or uneven surfaces.

- Inspect brake rotors for any signs of scoring, glazing, or warping.

Manual Inspection

- Check brake caliper operation by applying and releasing the brake pedal.

- Verify that brake pads move freely within the caliper.

Functional Test

- Conduct a road test to assess brake performance, including stopping distance and any unusual noises or vibrations.

- Inspect brake lights to ensure they are functioning correctly.

3. How do you troubleshoot faulty wiring on a trailer?

To troubleshoot faulty wiring, I follow a systematic approach:

- Visual Inspection: Examine wiring for any visible damage, corrosion, or loose connections.

- Continuity Test: Use a multimeter to check for continuity in wires and components, identifying any breaks or shorts.

- Voltage Measurement: Measure voltage at various points in the circuit to identify potential drops or surges.

- Signal Tracing: Utilize a signal tracer to locate the source of electrical signals and isolate faulty components.

4. What are the different types of trailer suspensions and how do they work?

- Leaf Spring Suspension: Uses leaf springs to absorb road shock and maintain axle alignment.

- Air Suspension: Employs air bags to provide a soft and adjustable ride, handling varying load weights.

- Torsion Axle Suspension: Utilizes twisted rubber or metal axles to absorb shock and provide stability.

- Hydraulic Suspension: Uses hydraulic cylinders to control suspension movement, offering a smooth ride even under heavy loads.

5. How do you safely operate a trailer lift?

To operate a trailer lift safely, I adhere to the following guidelines:

- Inspection: Check the lift for any damage or leaks before use.

- Stable Placement: Ensure the lift is placed on a level and stable surface.

- Proper Loading: Center the trailer on the lift platform and secure it with chains or straps.

- Lifting Procedure: Raise and lower the lift slowly and smoothly, avoiding sudden jerks or movements.

6. What steps do you take to maintain a trailer’s lighting system?

To maintain a trailer’s lighting system, I perform the following tasks:

- Regular Bulb Inspection: Check all bulbs for burnout or damage, replacing them as needed.

- Wiring Inspection: Examine wiring for any loose connections, corrosion, or damage, repairing or replacing as necessary.

- Connector Cleaning: Clean electrical connectors to prevent corrosion and ensure proper contact.

- Grounding: Verify that the trailer is properly grounded to avoid electrical issues.

7. Describe the procedure for replacing a trailer tire.

To replace a trailer tire, I follow this step-by-step process:

- Safety First: Park the trailer on a level surface, engage the parking brake, and place wheel chocks behind the opposite wheels.

- Loosen Lug Nuts: Use a lug wrench to loosen the lug nuts on the flat tire, but do not remove them completely.

- Jack Up Trailer: Position a jack near the flat tire and raise the trailer until there is approximately 6 inches of clearance.

- Remove Lug Nuts and Flat Tire: Fully remove the lug nuts and carefully pull off the flat tire.

- Mount New Tire: Align the new tire with the wheel and carefully lift it into place.

- Tighten Lug Nuts: Hand-tighten the lug nuts as much as possible, then use the lug wrench to fully tighten them in a star pattern.

- Lower Trailer: Slowly lower the trailer until it is resting on the ground.

- Final Tightening: Use a torque wrench to tighten the lug nuts to the manufacturer’s specified torque.

8. What are the indications that a trailer needs wheel alignment?

- Uneven Tire Wear: Excessive or uneven wear on one side of the tires.

- Steering Wheel Vibration: A noticeable vibration in the steering wheel while driving.

- Difficulty Steering: The trailer pulls to one side or requires constant adjustment.

- Camber or Toe Angle Issues: Visible misalignment of the wheels when viewed from the front or back.

9. How do you inspect a trailer’s frame for damage?

To inspect a trailer’s frame for damage, I follow a thorough approach:

- Visual Examination: Look for any visible cracks, bends, or deformations in the frame.

- Percussive Test: Use a hammer or mallet to tap along the frame, listening for any changes in sound that may indicate damage.

- Magnetic Particle Inspection: Apply magnetic particles to the frame and use a magnet to detect any areas of stress or cracks.

- Ultrasonic Testing: Utilize an ultrasonic device to send sound waves through the frame and identify any internal defects or corrosion.

10. What is your experience with DOT inspections?

In my previous role as a Trailer Mechanic, I was responsible for preparing trailers for DOT inspections. I have a thorough understanding of the DOT regulations and procedures, including:

- Inspecting for proper lighting, brakes, tires, and frame safety.

- Ensuring that all required documentation is up to date.

- Working closely with drivers to address any deficiencies.

- Maintaining a clean and organized work area to facilitate efficient inspections.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Trailer Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Trailer Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Trailer Mechanics are responsible for maintaining and repairing trailers to ensure they are in safe and working order. Their key responsibilities include:

1. Inspect and Diagnose Trailers

Inspect trailers for any damages or mechanical issues, such as worn brakes, faulty wiring, or damaged body panels.

- Identify and troubleshoot problems in a timely and efficient manner.

- Use diagnostic tools to determine the root cause of malfunctions.

2. Repair and Maintain Trailers

Perform repairs and maintenance tasks on trailers, including replacing worn parts, repairing damaged components, and lubricating moving parts.

- Ensure that all repairs and maintenance meet safety and quality standards.

- Keep detailed records of all repairs and maintenance performed.

3. Conduct Regular Maintenance

Conduct regular maintenance on trailers to prevent future problems, such as inspecting brakes, tires, and lights.

- Follow established maintenance schedules and checklists.

- Identify potential issues before they become major problems.

4. Assist in Other Tasks

May assist in other tasks related to trailer operations, such as loading and unloading cargo, cleaning trailers, and performing minor body repairs.

- Work as part of a team to ensure efficient operations.

- Maintain a clean and organized work area.

Interview Tips

Preparing for an interview for a Trailer Mechanic position is crucial to increase your chances of success. Here are some tips and tricks to help you ace the interview:

1. Research the Company and Role

Before the interview, research the company and the specific Trailer Mechanic role you are applying for. This will give you a good understanding of the company’s culture, values, and the job requirements.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest trends.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your relevant skills and experience as a Trailer Mechanic. Quantify your accomplishments whenever possible using specific examples.

- Describe your experience in diagnosing and repairing trailers.

- Provide examples of maintenance tasks you have performed.

3. Demonstrate Safety Knowledge

As a Trailer Mechanic, safety is paramount. Showcase your knowledge of safety protocols and regulations.

- Explain your understanding of DOT and OSHA regulations.

- Describe your experience in following safety procedures.

4. Be Prepared to Discuss Technical Knowledge

The interviewer will likely assess your technical knowledge of trailers. Be prepared to answer questions about trailer systems, components, and repair techniques.

- Review common trailer systems, such as braking, electrical, and suspension.

- Familiarize yourself with industry best practices for trailer maintenance.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Prepare questions related to the role, the company’s culture, or industry trends.

- Inquire about the company’s safety policies and training programs.

- Ask about opportunities for professional development.

Next Step:

Now that you’re armed with the knowledge of Trailer Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Trailer Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini