Are you gearing up for a career in Formulator Compounder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Formulator Compounder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

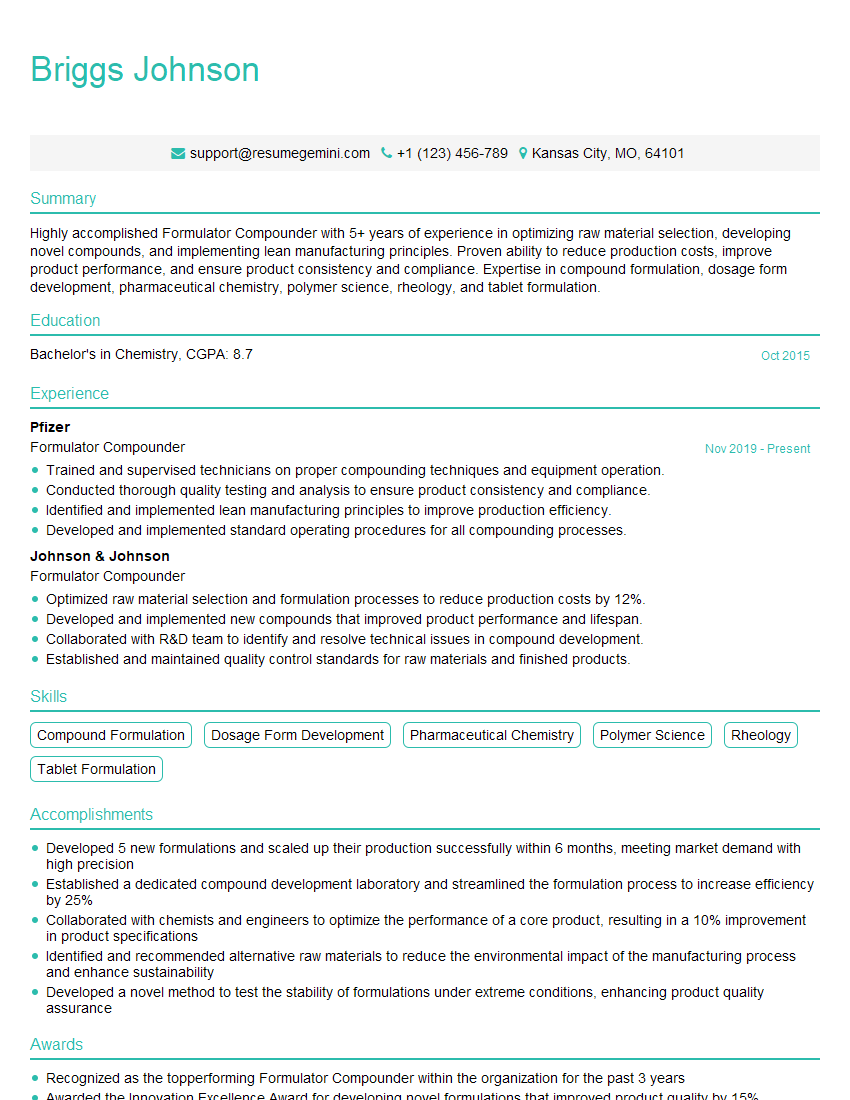

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Formulator Compounder

1. Describe the process of formulating a new compound for a specific application?

As a Formulator Compounder, I would follow a systematic approach to formulate a new compound for a specific application:

- Understand the application requirements and specifications: Determine the intended use, performance criteria, and environmental conditions for the final compound.

- Research and gather information: Conduct thorough research on existing materials, technologies, and industry trends to identify potential formulations.

- Select base materials: Choose suitable raw materials based on their chemical composition, physical properties, and compatibility with the intended application.

- Determine proportions and ratios: Calculate the optimal proportions of each raw material to achieve the desired properties and performance.

- Experimental formulation: Prepare and test small-scale batches to refine the formulation and optimize its characteristics.

- Scale-up and production: Once the formulation is finalized, scale up the process to produce larger quantities while maintaining consistency.

- Testing and evaluation: Conduct rigorous testing on the compound to ensure it meets the application requirements and industry standards.

2. Explain the role of additives in compound formulations and provide examples.

Additives for Enhancing Properties

- Plasticizers: Increase flexibility and workability of polymers.

- Antioxidants: Protect against degradation and oxidative damage.

- Colorants: Impart desired colors and aesthetic qualities.

Additives for Processing

- Mold release agents: Facilitate the removal of compounds from molds.

- Lubricants: Reduce friction and improve flow during processing.

- Anti-static agents: Prevent electrostatic buildup and improve handling.

3. Describe the different types of mixing and compounding techniques used in the industry.

- Extrusion: Melting and mixing materials under high pressure and temperature, then forcing them through a die.

- Injection molding: Melting and injecting molten materials into a mold under pressure.

- Compression molding: Compressing powdered materials in a mold under heat and pressure.

- Banbury mixing: Using high-energy mechanical shearing and mixing within a closed chamber.

- Two-roll mill: Mixing and masticating materials between two rotating rolls.

4. Explain the importance of quality control in compound formulation and production processes.

- Ensures product consistency: Maintains uniform properties and performance across production batches.

- Meets customer specifications: Verifies that the compound meets the agreed-upon requirements.

- Minimizes defects and rejections: Identifies and rectifies deviations from desired quality standards.

- Improves process efficiency: Optimizes production parameters to reduce waste and improve productivity.

- Complies with regulatory requirements: Ensures compliance with industry standards and regulations.

5. Describe the use of computer-aided design (CAD) in the development of compound formulations.

- Simulation and modeling: Predicts the behavior and properties of compounds based on input parameters.

- Optimization: Evaluates different formulation options and identifies the most suitable composition.

- Data analysis and visualization: Analyzes experimental data and presents results in a clear and concise manner.

- Collaboration: Facilitates communication and collaboration among researchers and engineers working on formulation development.

6. Explain the principles of dispersion and its significance in compound formulation.

Dispersion is the process of evenly distributing one material (dispersed phase) within another (continuous phase). It is crucial in compound formulation because it:

- Enhances properties: Improves mechanical strength, toughness, and thermal stability.

- Controls rheology: Influences the flow and handling characteristics of the compound.

- Affects appearance: Determines the color, opacity, and surface texture of the final product.

7. Describe the different types of testing methods used to evaluate the properties of compounds.

- Mechanical testing: Tensile strength, flexural strength, impact resistance, hardness.

- Thermal analysis: Melting point, glass transition temperature, thermal stability.

- Rheological testing: Flow properties, viscosity, shear strength.

- Electrical testing: Conductivity, dielectric constant, insulation resistance.

- Environmental testing: Resistance to UV radiation, weathering, chemicals.

8. Explain the concept of compound stability and the factors that affect it.

Compound stability refers to the ability of a compound to maintain its properties over time and under various conditions. Factors affecting stability include:

- Temperature: Extreme temperatures can cause degradation or crystallization.

- Oxygen exposure: Oxidation can lead to discoloration, embrittlement, or loss of strength.

- Moisture: Absorption of moisture can affect mechanical properties and electrical performance.

- Light exposure: UV radiation can cause chain scission and surface degradation.

9. Describe the role of surface modification in compound development and its benefits.

- Improved adhesion: Enhances bonding with other materials, increasing joint strength.

- Enhanced wettability: Reduces surface tension and improves dispersion in solvents or coatings.

- Controlled porosity: Modifies surface structure to achieve specific gas or liquid permeability.

- Antimicrobial properties: Incorporates antimicrobial agents to inhibit microbial growth on the surface.

- Electrical conductivity: Alters surface properties to improve electrical conductivity or resistance.

10. Explain the difference between thermoset and thermoplastic compounds, and provide examples.

- Thermoset compounds: Irreversible chemical change occurs upon curing, forming a rigid, cross-linked structure. Examples: epoxies, polyurethanes, thermoset plastics.

- Thermoplastic compounds: Reversible physical change occurs upon heating and cooling, allowing for repeated molding and reshaping. Examples: polyethylene, polypropylene, thermoplastic elastomers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Formulator Compounder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Formulator Compounder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Formulator Compounder plays a crucial role in the development and manufacturing of a wide range of chemical products, including cosmetics, pharmaceuticals, and industrial materials. Key job responsibilities include:

1. Formulation Development

Research and develop new or improved formulations for products, considering factors such as desired properties, cost, and safety.

- Conduct experiments and analyze results to optimize formulations.

- Collaborate with engineers and scientists to ensure formulations meet technical requirements.

2. Compound Production

Supervise and participate in the manufacturing process, ensuring adherence to established procedures and quality standards.

- Monitor and control equipment to produce compounds according to specifications.

- Troubleshoot production issues and make necessary adjustments.

3. Quality Control

Conduct or oversee testing procedures to ensure the quality and consistency of products.

- Analyze samples to verify compliance with safety and regulatory standards.

- Document and report on quality control data.

4. Regulatory Compliance

Stay abreast of industry regulations and ensure compliance with relevant laws and standards.

- Maintain accurate records and documentation.

- Participate in audits and inspections.

Interview Tips

To ace an interview for a Formulator Compounder position, candidates should prepare thoroughly and showcase their technical knowledge, problem-solving skills, and attention to detail.

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing. Understand the specific responsibilities and requirements of the Formulator Compounder role.

- Visit the company website, read industry publications, and connect with employees on LinkedIn.

- Review the job description carefully and identify key skills and experiences that are sought after.

2. Highlight Relevant Experience and Skills

In your resume and interview, emphasize your experience in formulation development, compound production, quality control, and regulatory compliance. Quantify your accomplishments using specific examples and metrics.

- Provide details on successful projects where you played a key role in developing or improving formulations.

- Share examples of how you have implemented quality control measures and ensured compliance with regulatory standards.

3. Demonstrate Technical Knowledge

Formulator Compounders are expected to have a strong understanding of chemistry, materials science, and manufacturing processes. Be prepared to discuss complex technical concepts and their application in the role.

- Review basic chemistry principles and common formulation components.

- Familiarize yourself with different compounding techniques and their advantages and disadvantages.

4. Practice Problem Solving

Formulator Compounders often encounter challenges during the formulation and production process. In the interview, prepare to discuss how you would approach and solve common problems in the field.

- Consider scenarios involving inconsistent product quality, equipment malfunctions, or regulatory changes.

- Outline your problem-solving approach, including gathering information, analyzing data, and developing solutions.

5. Showcase Attention to Detail

Formulation and production processes require meticulous attention to detail. In the interview, demonstrate your ability to focus on precision and accuracy.

- Share examples of how you have ensured compliance with complex specifications and quality standards.

- Emphasize your ability to work independently and manage multiple tasks effectively.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Formulator Compounder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Formulator Compounder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.