Feeling lost in a sea of interview questions? Landed that dream interview for Plastic Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Plastic Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

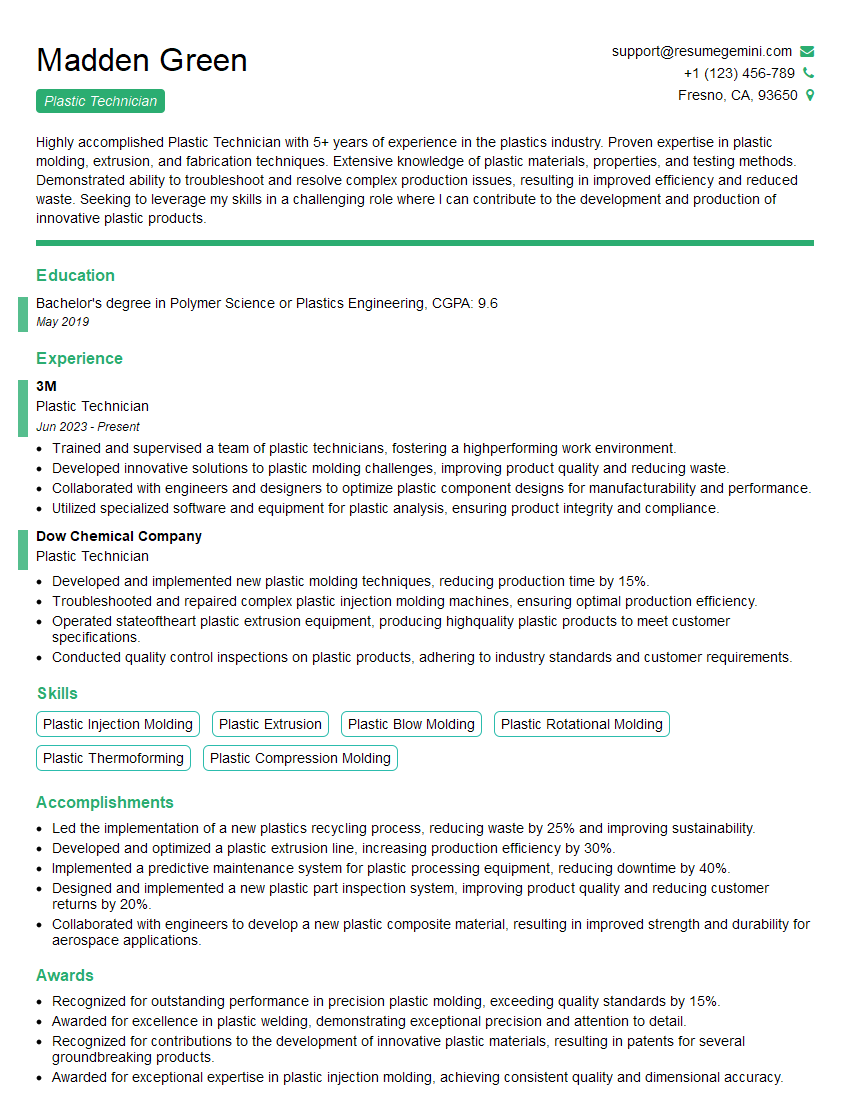

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Technician

1. Describe the different types of plastics you have worked with and their properties?

As a Plastic Technician, I have worked with a wide range of plastics, each with its unique properties. These include:

- Polyethylene (PE): Known for its flexibility, low cost, and resistance to chemicals and moisture.

- Polypropylene (PP): Characterized by its high strength, durability, and resistance to heat.

- Polyvinyl chloride (PVC): Versatile and cost-effective, with good electrical insulation and resistance to acids and bases.

- Polyethylene terephthalate (PET): Commonly used for beverage bottles and food packaging due to its clarity, strength, and recyclability.

- Acrylonitrile butadiene styrene (ABS): Known for its toughness, impact resistance, and ability to withstand high temperatures.

2. Explain the process of injection molding in detail?

Injection Molding Stages:

- Clamping: The mold halves are closed and clamped securely.

- Injection: Molten plastic is injected into the mold cavity under high pressure.

- Cooling: The plastic solidifies and cools within the mold.

- Ejection: The mold opens, and the finished part is ejected.

Role of Plastic Technician:

- Set up and operate injection molding machines.

- Adjust process parameters to optimize production.

- Monitor and maintain mold temperature, pressure, and cycle times.

- Inspect finished parts for defects and quality.

3. What are the primary responsibilities of a Plastic Technician in a manufacturing environment?

- Operate and maintain plastic processing machinery: Injection molding machines, extruders, blow molding machines, and thermoformers.

- Set up and adjust process parameters: Temperature, pressure, cycle times, and mold settings.

- Monitor and control production processes: Ensure quality, reduce defects, and optimize efficiency.

- Inspect and test finished products: Check dimensions, surface finish, and mechanical properties.

- Troubleshoot and resolve production issues: Identify and correct problems with machinery, materials, or processes.

4. Describe the different techniques used to join plastic parts?

- Adhesives: Using adhesives to bond plastic parts together.

- Welding: Melting and fusing plastic surfaces to create a strong bond.

- Mechanical fasteners: Utilizing screws, bolts, or rivets to hold plastic parts in place.

- Thermal bonding: Joining plastic parts by applying heat and pressure.

- Ultrasonic welding: Using high-frequency sound waves to create friction and bonding between plastic surfaces.

5. What are the safety precautions that should be taken when working with plastics?

- Wear appropriate protective gear: Gloves, safety glasses, and respirators.

- Follow proper handling procedures: Avoid contact with molten plastic or sharp edges.

- Ensure adequate ventilation: Keep the work area well-ventilated to prevent exposure to fumes or dust.

- Dispose of waste materials properly: Follow environmental regulations for plastic waste disposal.

- Stay informed about potential hazards: Be aware of the specific properties and risks associated with different plastics.

6. How do you stay up-to-date with the latest advancements in plastics technology?

- Attend industry conferences and seminars: Network with professionals and learn about new materials and techniques.

- Read trade publications and technical journals: Stay informed about emerging technologies and best practices.

- Participate in online forums and discussion groups: Engage with other plastics professionals and exchange knowledge.

- Conduct research and experimentation: Explore new materials and processes to enhance skills and stay ahead of the curve.

7. Describe a challenging project you worked on as a Plastic Technician and how you overcame the obstacles?

In my previous role, I encountered a complex project involving the production of a high-precision plastic component for a medical device. The challenge arose when the component exhibited excessive shrinkage and dimensional variations. I conducted a thorough analysis of the process parameters and identified a mismatch between the mold temperature and the plastic material’s crystallization behavior. By adjusting the mold temperature and cooling rate, I was able to minimize shrinkage and achieve the desired dimensional accuracy, ensuring the successful completion of the project.

8. How do you ensure the quality of plastic products?

- Implement quality control procedures: Establish inspection criteria and protocols.

- Conduct regular inspections: Examine finished products for defects and compliance with specifications.

- Use measuring instruments and gauges: Ensure dimensional accuracy and surface finish meet requirements.

- Analyze production data: Monitor key performance indicators to identify potential quality issues.

- Provide feedback to production team: Identify areas for improvement and implement corrective actions.

9. What are the different types of plastics testing you are familiar with?

- Tensile testing: Determines the strength and elasticity of plastics.

- Flexural testing: Measures the bending strength and stiffness of plastics.

- Impact testing: Assesses the resistance of plastics to impact forces.

- Thermal analysis: Identifies the thermal properties of plastics, such as melting point and glass transition temperature.

- Chemical resistance testing: Evaluates the ability of plastics to resist degradation from chemicals and solvents.

10. How do you maintain and calibrate plastics processing equipment?

- Regular cleaning and maintenance: Clean equipment to prevent contamination and wear.

- Calibration of gauges and instruments: Ensure accuracy and precision of measurements.

- Monitoring of equipment performance: Track key parameters to identify potential issues.

- Preventive maintenance: Schedule regular inspections and servicing to minimize downtime.

- Collaboration with maintenance team: Work closely with maintenance professionals for repairs and upgrades.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Technicians are responsible for a wide range of tasks in the plastics industry, from operating and maintaining machinery to inspecting and testing finished products. Their primary duties include:

1. Operating and Maintaining Machinery

Plastic Technicians operate and maintain a variety of machinery used in the plastics industry, including injection molding machines, extruders, and thermoforming machines. They are responsible for setting up and adjusting the machinery, as well as troubleshooting and repairing any problems that arise.

- Set up and adjust machinery to meet production specifications

- Operate machinery to produce plastic products

- Troubleshoot and repair machinery

- Perform preventive maintenance on machinery

2. Inspecting and Testing Finished Products

Plastic Technicians inspect and test finished plastic products to ensure that they meet quality standards. They check for defects, such as cracks, scratches, and bubbles, and they also test the products’ strength and durability.

- Inspect finished products for defects

- Test products to ensure they meet quality standards

- Identify and correct defects

- Maintain quality control records

3. Developing and Improving Production Processes

Plastic Technicians work with engineers and other staff to develop and improve production processes. They identify ways to reduce waste, increase efficiency, and improve product quality.

- Identify ways to improve production processes

- Develop and implement new production techniques

- Train operators on new production techniques

4. Providing Technical Support

Plastic Technicians provide technical support to other employees, including operators, engineers, and customers. They answer questions about the machinery and production processes, and they help to troubleshoot problems.

- Answer questions about machinery and production processes

- Help to troubleshoot problems

- Provide training on new machinery and production techniques

Interview Tips

Preparing for a job interview can be a daunting task, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the Company and Position

Before you go on an interview, it is important to do your research. Learn as much as you can about the company and the position you are applying for. This will help you to answer questions intelligently and show the interviewer that you are genuinely interested in the job.

- Visit the company’s website

- Read articles about the company and industry

- Talk to people who work at the company

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?” It is helpful to practice answering these questions ahead of time so that you can deliver your answers confidently and clearly.

- Brainstorm a list of common interview questions

- Write out your answers to these questions

- Practice answering these questions out loud

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This shows the interviewer that you are respectful of their time and that you are serious about the job.

- Choose clothing that is clean, pressed, and appropriate for the job you are applying for

- Arrive at the interview on time or a few minutes early

4. Be Yourself and Be Enthusiastic

It is important to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be enthusiastic about the job and the company, and show the interviewer that you are genuinely interested in the opportunity.

- Be genuine and authentic

- Show the interviewer that you are enthusiastic about the job

- Be positive and upbeat

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plastic Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!