Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Assembly Repairer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Assembly Repairer so you can tailor your answers to impress potential employers.

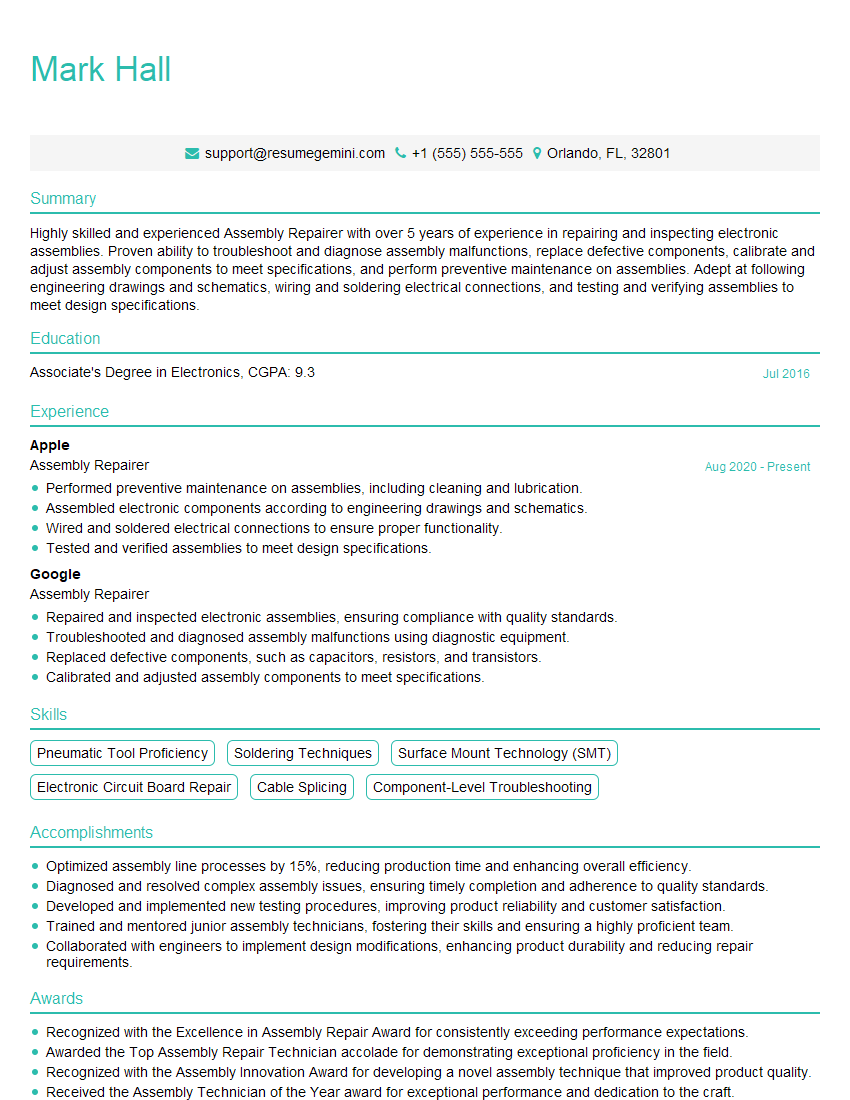

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Assembly Repairer

1. Describe the process of diagnosing a faulty assembly.

• Begin by gathering information about the symptoms of the fault, including when it occurs and under what conditions.

• Visually inspect the assembly for any obvious damage or defects.

• Use diagnostic tools, such as multimeters and oscilloscopes, to test the assembly’s electrical and mechanical functions.

• Refer to technical documentation and schematics to identify potential causes of the fault.

• Perform a series of tests to isolate the faulty component or components.

2. What are the different types of assembly repairs that you are familiar with?

Mechanical repairs

- Repairing or replacing damaged components

- Realigning or adjusting mechanical parts

- Lubricating moving parts

Electrical repairs

- Repairing or replacing faulty electrical components

- Soldering and desoldering connections

- Testing and troubleshooting electrical circuits

3. What tools and equipment are essential for assembly repair?

• Multimeters

• Oscilloscopes

• Soldering irons and desoldering pumps

• Hand tools, such as screwdrivers, wrenches, and pliers

• Precision measuring tools, such as calipers and micrometers

• Diagnostic software and firmware update tools

4. How do you ensure that a repaired assembly meets the required specifications?

• Follow established repair procedures and quality control standards.

• Test the repaired assembly thoroughly to verify its functionality.

• Calibrate or adjust the assembly to meet the required specifications.

• Document the repair process and the results of the tests.

5. Describe the importance of safety when performing assembly repairs.

• Wear appropriate personal protective equipment, such as safety glasses and gloves.

• Use tools and equipment safely and properly.

• Follow lockout/tagout procedures when working on electrical assemblies.

• Handle hazardous materials, such as solvents and fluxes, with care.

• Be aware of potential hazards, such as sharp edges and electrical shock.

6. How do you stay up-to-date with the latest assembly repair techniques?

• Attend industry conferences and workshops

• Read technical journals and articles

• Participate in online forums and discussion groups

• Take training courses offered by manufacturers

• Collaborate with other assembly repair technicians and engineers

7. What are the challenges of working as an Assembly Repairer?

• Diagnosing complex faults

• Repairing delicate or high-precision assemblies

• Meeting tight deadlines

• Working with hazardous materials and equipment

• Keeping up with rapidly changing technology

8. What are the rewards of working as an Assembly Repairer?

• Job satisfaction from solving problems and repairing complex assemblies

• Opportunities for professional growth and development

• Competitive salary and benefits

• Opportunity to work with cutting-edge technology

• Making a contribution to the manufacturing process

9. What is your experience with surface mount technology (SMT) repairs?

• Inspected and repaired SMT components on printed circuit boards (PCBs).

• Used specialized tools and equipment, such as rework stations and microscopes.

• Soldered and desoldered SMT components with precision.

• Followed industry standards and best practices for SMT repair.

10. Describe your experience with troubleshooting and repairing electronic control systems.

• Analyzed and diagnosed faults in electronic control systems using diagnostic tools and techniques.

• Repaired and replaced faulty components, including sensors, actuators, and microcontrollers.

• Calibrated and adjusted control systems to ensure optimal performance.

• Documented repair procedures and test results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Assembly Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Assembly Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Assembly Repairers, as the title implies, are responsible for a wide range of maintenance and repair tasks on assembly lines in various manufacturing environments. Their primary goal is to ensure that machines, tools, and equipment related to assembly processes operate smoothly and efficiently.

1. Maintenance Duties

Assembly Repairers perform preventive maintenance tasks on a regular basis. They identify potential problems with equipment by conducting thorough inspections, servicing and lubricating moving parts, tightening bolts and screws, and adhering to established maintenance schedules. By taking these proactive measures, they prevent larger issues from arising, minimizing downtime and ensuring smooth production flow.

- Conduct regular inspections to identify any potential issues early on.

- Service and lubricate moving parts to maintain optimal performance.

- Tighten bolts and screws to ensure stability and prevent unexpected breakdowns.

- Follow established maintenance schedules to keep equipment in top condition.

2. Repair Tasks

When machines or equipment malfunction or break down, Assembly Repairers step in to diagnose and fix the problems. They use their knowledge of mechanics, electrical systems, and pneumatics to identify faulty components, replace worn parts, and perform necessary repairs. Their ability to troubleshoot and resolve issues quickly and effectively keeps assembly lines running and minimizes production delays.

- Diagnose and repair mechanical, electrical, and pneumatic system problems.

- Replace worn or damaged components to restore functionality.

- Troubleshoot issues promptly to minimize production downtime.

- Follow safety protocols and procedures while performing repairs.

3. Installation and Alignment

Assembly Repairers may also be involved in the installation and alignment of new or refurbished machinery. They ensure that equipment is properly positioned, leveled, and adjusted to meet operational requirements. They also work closely with production teams to ensure a smooth transition during equipment upgrades or replacements.

- Install new or refurbished machinery according to specifications.

- Align and level equipment to ensure optimal performance.

- Collaborate with production teams to manage equipment transitions.

- Follow safety guidelines during installation and alignment procedures.

4. Troubleshooting and Problem-solving

Assembly Repairers are often the first line of defense when production issues arise. They possess strong analytical and problem-solving skills, enabling them to identify the root cause of problems and develop effective solutions. By pinpointing the source of issues and implementing appropriate measures, they minimize the impact on production schedules and ensure efficient operations.

- Identify and analyze production issues to determine their root causes.

- Develop and implement solutions to resolve problems effectively.

- Collaborate with other departments to gather necessary information.

- Document problem-solving processes and solutions.

Interview Tips

Preparing thoroughly for an Assembly Repairer interview is crucial to showcase your skills, experience, and enthusiasm for the role. Here are some valuable tips to help you ace your interview:

1. Research the Company and Role

Take the time to learn about the company’s industry, business operations, and specific job requirements. This will demonstrate your interest in the opportunity and enable you to tailor your responses to the interviewer’s questions.

- Visit the company’s website and social media pages to gather information.

- Review industry news and trends to understand the company’s position within the market.

- Thoroughly read the job description and identify the key skills and responsibilities.

2. Highlight Your Technical Skills

As an Assembly Repairer, your technical expertise is crucial. Emphasize your proficiency in mechanics, electrical systems, and pneumatics. Provide specific examples of how you have used these skills to diagnose and repair equipment in previous roles.

- Describe your experience troubleshooting and resolving complex mechanical issues.

- Share examples of how you have repaired electrical systems, including wiring, motors, and controls.

- Demonstrate your understanding of pneumatic systems and their applications in assembly lines.

3. Emphasize Your Problem-solving Abilities

Problem-solving is a core competency for Assembly Repairers. Highlight your ability to identify and analyze production issues, develop effective solutions, and implement them to minimize downtime. Share specific examples of how you have successfully resolved problems in previous roles.

- Describe a situation where you identified a recurring problem and implemented a solution that significantly reduced downtime.

- Share an example of how you collaborated with other departments to gather information and develop a comprehensive solution.

- Explain how you document problem-solving processes and solutions to ensure continuous improvement.

4. Showcase Your Communication and Teamwork Skills

Assembly Repairers often work in teams and collaborate with other departments. Demonstrate your strong communication and interpersonal skills by providing examples of how you have effectively communicated with colleagues, supervisors, and production staff. Emphasize your ability to work independently and as part of a team.

- Describe how you effectively communicate technical information to non-technical personnel.

- Share an example of how you collaborated with a team to resolve a complex production issue.

- Explain how you manage your time and prioritize tasks while working independently.

5. Prepare Questions for the Interviewer

Asking well-thought-out questions at the end of the interview shows your interest in the role and the company. Prepare questions that demonstrate your genuine curiosity about the position, the company’s culture, and the industry. This is also an opportunity to clarify any aspects of the role that you may be unsure about.

- Inquire about the company’s plans for future growth and expansion.

- Ask about opportunities for professional development and training.

- Request insights into the company’s commitment to safety and quality.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Assembly Repairer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Assembly Repairer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.