Feeling lost in a sea of interview questions? Landed that dream interview for Viscosity Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Viscosity Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

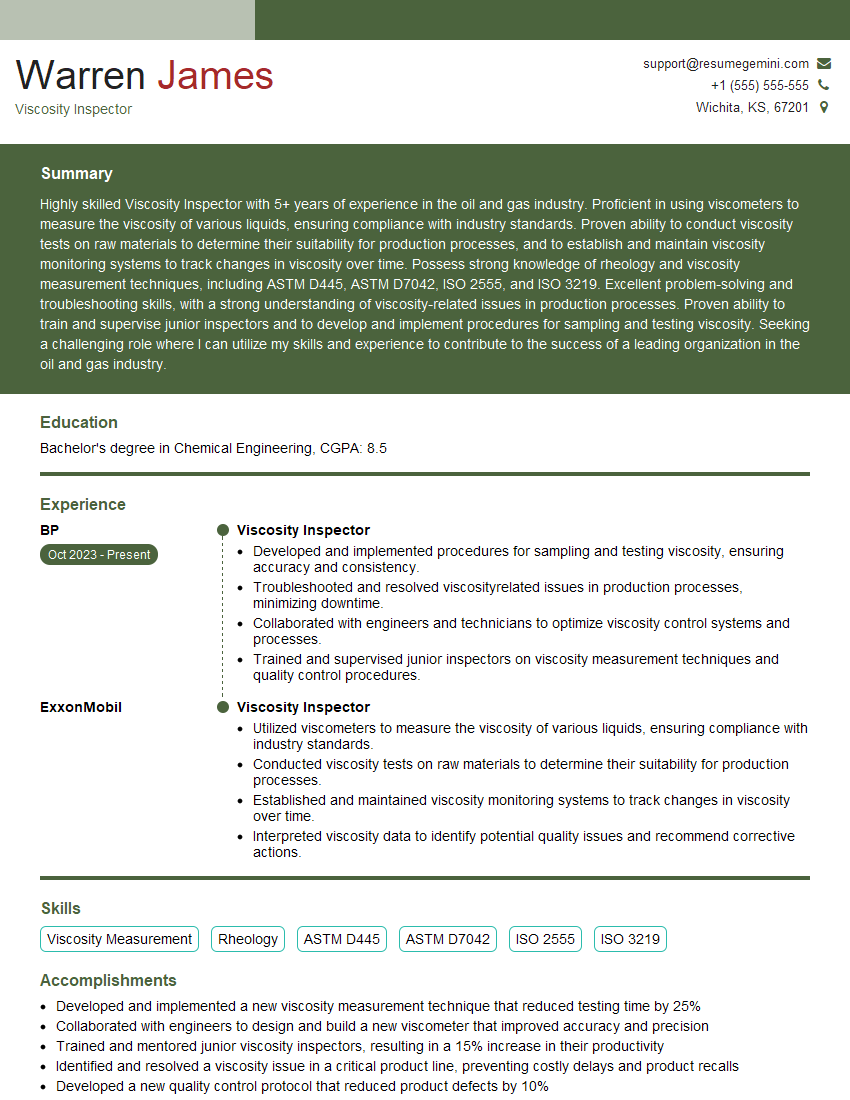

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Viscosity Inspector

1. What are the different types of viscometers used in the industry, and how do you choose the appropriate type for a specific application?

There are various types of viscometers used in the industry, such as:

- Capillary viscometers: Suitable for measuring the viscosity of Newtonian fluids. They measure the time taken for a fluid to flow through a capillary tube.

- Cone-and-plate viscometers: Ideal for measuring the viscosity of non-Newtonian fluids. They measure the torque required to rotate a cone submerged in the fluid.

- Falling ball viscometers: Determine the viscosity of opaque or highly viscous fluids. They measure the time taken for a ball to fall through the fluid.

- Rotational viscometers: Measure the viscosity of fluids by rotating a spindle or bob immersed in the fluid and measuring the torque required.

Choosing the appropriate viscometer depends on factors such as:

- Fluid type (Newtonian or non-Newtonian)

- Viscosity range

- Sample volume

- Temperature requirements

2. Describe the principles of operation of a rotational viscometer.

- Rotational viscometers operate by rotating a spindle or bob immersed in the fluid at a specific speed.

- The fluid exerts a drag force on the spindle due to its viscosity, which is measured by a sensor.

- The measured torque is directly proportional to the fluid’s viscosity.

- Some rotational viscometers can also measure yield stress, which is the minimum stress required to initiate flow.

3. What are the factors that can affect the accuracy of viscosity measurements?

Factors that can affect the accuracy of viscosity measurements include:

- Proper calibration of the viscometer

- Ensuring the sample is free of contaminants and bubbles

- Using the appropriate viscometer for the fluid type and viscosity range

- Maintaining the correct temperature during measurement

- Proper sample handling and preparation

4. How do you calibrate a rotational viscometer?

Calibration of a rotational viscometer involves:

- Using certified calibration fluids of known viscosity

- Performing measurements at different speeds and comparing the results to the known values

- Adjusting the viscometer’s calibration parameters to match the calibration fluid values

- Regularly checking the calibration to ensure accuracy

5. Describe the different types of flow behavior exhibited by fluids.

- Newtonian fluids: Exhibit a linear relationship between shear stress and shear rate. The viscosity of Newtonian fluids remains constant regardless of the applied shear rate.

- Non-Newtonian fluids: Exhibit a non-linear relationship between shear stress and shear rate. Their viscosity can change depending on the applied shear rate.

Non-Newtonian fluids can further be classified into:

- Shear thickening fluids: Their viscosity increases with increasing shear rate.

- Shear thinning fluids: Their viscosity decreases with increasing shear rate.

6. What are the advantages of using a digital viscometer over an analog viscometer?

- Improved accuracy and precision: Digital viscometers provide more accurate and precise measurements compared to analog viscometers.

- Data logging and analysis: Digital viscometers can store and analyze data, allowing for easy data management and further analysis.

- Temperature control: Some digital viscometers have built-in temperature control, ensuring accurate measurements at specific temperatures.

- User-friendly interface: Digital viscometers often have intuitive and user-friendly interfaces, making them easy to operate.

7. What are the safety precautions to consider when using a viscometer?

Safety precautions to consider when using a viscometer include:

- Wearing appropriate personal protective equipment (PPE) such as gloves and eye protection.

- Ensuring the viscometer is properly grounded to prevent electrical hazards.

- Using the viscometer in a well-ventilated area to avoid exposure to hazardous fumes or vapors.

- Following proper handling and disposal procedures for hazardous materials.

8. How do you maintain and troubleshoot a rotational viscometer?

Maintenance and troubleshooting of a rotational viscometer involve:

- Regular cleaning of the viscometer and its components

- Checking the calibration regularly and recalibrating if necessary

- Inspecting the viscometer for any damage or wear

- Troubleshooting common issues such as incorrect readings, leaks, or mechanical problems

9. What is the importance of viscosity measurement in the petroleum industry?

- Viscosity is a crucial factor in the transportation and processing of petroleum products.

- Viscosity affects the flowability of crude oil and refined products through pipelines.

- Viscosity measurements help determine the efficiency and effectiveness of refining processes.

- Viscosity data is used to optimize blending operations and ensure the desired product quality.

10. Describe your experience in using viscometers for quality control in the manufacturing industry.

In my previous role as a Viscosity Inspector in the manufacturing industry, I was responsible for:

- Measuring the viscosity of various products using different viscometers, including rotational and capillary viscometers.

- Ensuring that the viscosity of products met the specified quality standards.

- Calibrating and maintaining viscometers to maintain accuracy and precision.

- Troubleshoot and resolve any issues related to viscosity measurements.

- Prepared and maintained documentation related to viscosity measurements and quality control procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Viscosity Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Viscosity Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Viscosity Inspectors are responsible for ensuring that the viscosity of products meets the required specifications. They perform a variety of tests to measure viscosity, and they use their findings to make adjustments to the production process as needed.

1. Conduct Viscosity Tests

Viscosity Inspectors conduct a variety of tests to measure the viscosity of products. These tests may include:

- Capillary viscometry: This test measures the time it takes for a liquid to flow through a capillary tube. The viscosity of the liquid is calculated based on the flow time.

- Rotational viscometry: This test measures the torque required to rotate a spindle in a liquid. The viscosity of the liquid is calculated based on the torque measurement.

- Falling ball viscometry: This test measures the time it takes for a ball to fall through a liquid. The viscosity of the liquid is calculated based on the fall time.

2. Analyze Test Results

Viscosity Inspectors analyze the results of their tests to determine the viscosity of the product. They compare the results to the required specifications, and they make adjustments to the production process as needed.

3. Maintain Testing Equipment

Viscosity Inspectors are responsible for maintaining the testing equipment they use. They perform regular calibration and maintenance checks to ensure that the equipment is accurate and reliable.

4. Report Findings

Viscosity Inspectors report their findings to their supervisors and other members of the production team. They provide information on the viscosity of the products, and they make recommendations for adjustments to the production process.

Interview Tips

Preparing for an interview for a Viscosity Inspector position can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also give you a better idea of what the job entails.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to think about how you will answer these questions, and practice your answers out loud.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience and qualifications. Be prepared to talk about your experience in viscosity testing, and highlight any specific skills or knowledge that you have that would be relevant to the position.

4. Be Enthusiastic and Professional

First impressions matter, so make sure you dress professionally and arrive on time for your interview. Be enthusiastic and positive, and show the interviewer that you are interested in the position and that you are eager to learn more about the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Viscosity Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.