Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Milking Machine Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

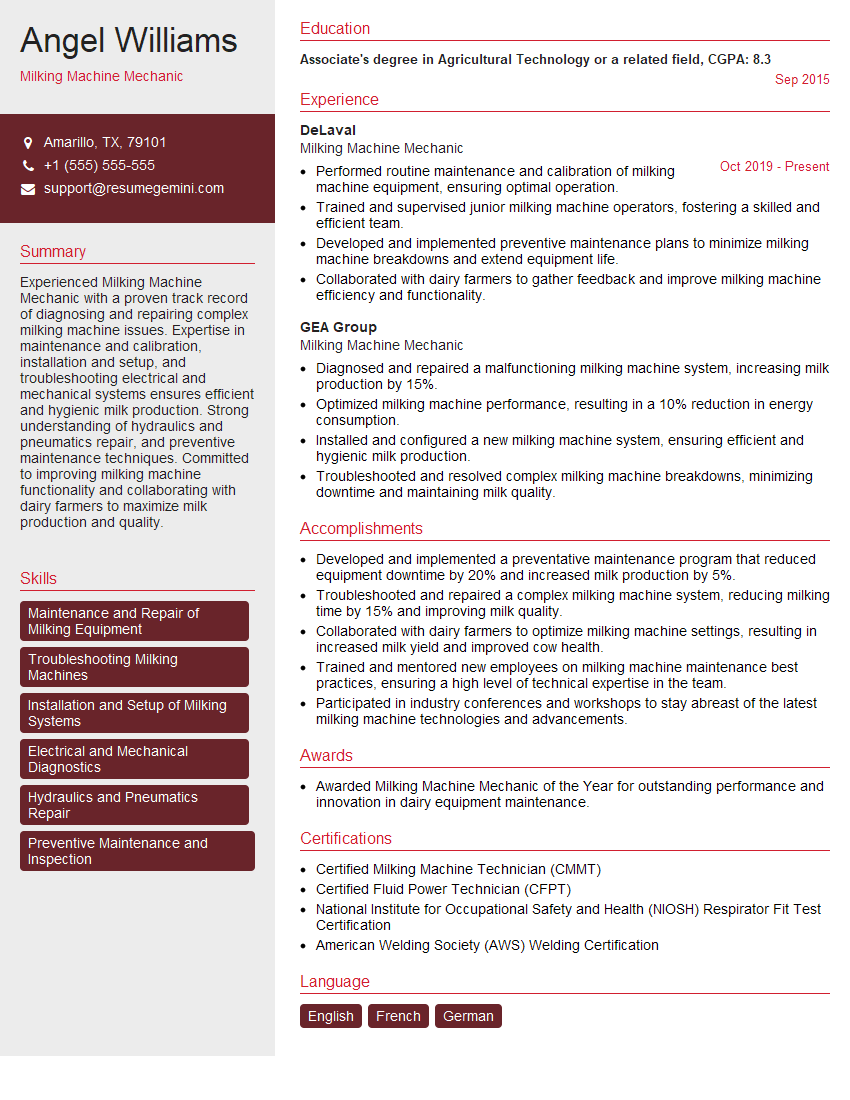

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Milking Machine Mechanic

1. Describe the key components of a milking machine and explain their functions?

- Vacuum pump: Creates the vacuum that draws milk from the cow’s udder.

- Milking claw: Connects the vacuum pump to the cow’s teats.

- Milking liner: Inflatable rubber sleeves that massage the cow’s teats and draw milk into the claw.

- Milk receiver: Collects the milk from the claws.

- Pipeline: Transports the milk from the receiver to the bulk tank.

2. How do you troubleshoot a milking machine that is not milking properly?

Vacuum issues

- Check the vacuum level and ensure it meets the manufacturer’s specifications.

- Inspect the vacuum pump for any leaks or damage.

- Clean or replace the vacuum filter.

Milking system issues

- Check the milking claws and liners for any damage or wear.

- Ensure the claw is properly positioned on the cow’s teats.

- Inspect the milk receiver for any blockages.

3. What are the common maintenance procedures for milking machines?

- Daily: Check the vacuum level, inspect the claw and liner for damage, and clean the milk receiver.

- Weekly: Replace the vacuum filter, and clean the vacuum pump.

- Monthly: Inspect the pipeline for any leaks or blockages, and calibrate the milking system.

4. What safety precautions should be taken when working with milking machines?

- Wear appropriate protective clothing, including gloves and earplugs.

- Ensure the milking machine is properly grounded.

- Keep the work area clean and free of tripping hazards.

- Follow manufacturer’s instructions for operating and maintaining the milking machine.

5. What are the different types of milking machines?

- Bucket milkers: Manual or electric milkers that collect milk into a bucket.

- Pipeline milkers: Automated milkers that collect milk into a pipeline and transport it to a bulk tank.

- Rotary milkers: Automated milkers that rotate the cows through a milking parlor.

6. How do you calibrate a milking machine?

- Connect a vacuum gauge to the milking claw.

- Operate the milking machine and adjust the vacuum regulator until the desired vacuum level is achieved.

- Check the vacuum level at different points in the milking system, including the milk receiver and pipeline, to ensure consistent vacuum distribution.

7. What are the advantages and disadvantages of using a milking machine?

Advantages

- Increased milk production due to efficient milking.

- Reduced labor costs and improved efficiency.

- Improved milk quality through automated milking practices.

Disadvantages

- Initial investment cost.

- Regular maintenance and calibration required.

- Potential for mechanical failures.

8. How do you ensure the proper maintenance of milking machine systems?

- Establish a regular maintenance schedule and adhere to it.

- Train operators on proper milking procedures and maintenance tasks.

- Keep a record of maintenance activities, including inspections, repairs, and replacements.

- Use high-quality replacement parts and follow manufacturer’s recommendations.

9. Describe the principles of mastitis prevention in milking machine systems.

- Maintain proper milking procedures, including pre- and post-milking teat preparation.

- Ensure the milking machine is properly calibrated and maintained.

- Regularly inspect the milking equipment for any damage or wear.

- Implement a milking routine that minimizes cow stress and promotes teat health.

10. What are the emerging trends in milking machine technology?

- Automated milking systems with robotic milkers.

- Real-time milk quality monitoring and data analysis.

- Integration with farm management software for improved efficiency.

- Energy-efficient milking systems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Milking Machine Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Milking Machine Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Milking machine mechanics play a crucial role in ensuring the efficient and hygienic operation of milking systems on dairy farms. Their key responsibilities include:

1. Troubleshooting and Repairing Milking Equipment

Diagnose and resolve malfunctions, breakdowns, and performance issues in milking machines, vacuum systems, and related equipment.

- Inspect and test milking systems to identify potential problems.

- Perform repairs and adjustments to restore equipment functionality.

2. Maintenance and Calibration

Conduct regular preventive maintenance, such as cleaning, lubrication, and calibration, to maintain optimal equipment performance and prevent breakdowns.

- Clean and disinfect milking machines and associated equipment.

- Lubricate moving parts to reduce friction and wear.

- Calibrate sensors and other components to ensure accurate readings and proper functioning.

3. Installation and Upgrades

Install, modify, and upgrade milking systems and equipment according to industry standards and safety regulations.

- Install new milking machines and pipelines.

- Upgrade existing systems with improved or more efficient components.

- Ensure compliance with regulatory requirements and industry best practices.

4. Training and Supervision

Provide training and guidance to dairy farm staff on the proper operation and maintenance of milking equipment.

- Train staff on milking machine operation, troubleshooting, and cleaning procedures.

- Supervise staff to ensure adherence to established protocols.

- Identify training needs and develop training programs.

Interview Tips

Preparing well for an interview as a milking machine mechanic is essential to showcase your skills and increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the dairy farm or company you are applying to. Learn about their operations, milking practices, and any specific challenges they may face. Research the industry to stay up to date on trends and best practices.

- Visit the company’s website and social media pages.

- Read industry publications and attend webinars.

- Network with professionals in the field.

2. Highlight Your Skills and Experience

Tailor your resume and cover letter to the specific job requirements. Emphasize your technical skills related to milking machine repair and maintenance. Quantify your accomplishments and provide specific examples of your work experience.

- Use keywords from the job description in your resume.

- Provide concrete examples of troubleshooting and repair projects you have completed.

- Quantify your results, such as reduced maintenance costs or increased milk production.

3. Demonstrate Your Knowledge and Passion

Be prepared to discuss your knowledge of milking machine technology, industry regulations, and best practices. Show your passion for the field and your commitment to providing excellent service to dairy farmers.

- Discuss new developments in milking equipment and techniques.

- Explain your safety procedures and the importance of hygiene in milking operations.

- Share your experiences working with farmers and supporting their businesses.

4. Emphasize Your Problem-Solving Abilities

Milking machine mechanics often face unexpected challenges. In the interview, highlight your ability to troubleshoot problems quickly and effectively. Give examples of complex issues you have resolved and explain your thought process.

- Describe a situation where you identified the root cause of a persistent problem.

- Explain how you used technical knowledge and logical reasoning to troubleshoot and repair equipment.

- Discuss the importance of effective communication with clients and colleagues.

5. Practice and Prepare

Practice answering common interview questions, such as “Tell me about your experience” and “Why are you interested in this role?” Speak clearly and confidently, and be prepared to provide specific examples of your skills and qualifications.

- Conduct mock interviews with a friend or family member.

- Record yourself answering questions and review your responses.

- Be confident and articulate in your communication.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Milking Machine Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Milking Machine Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.