Feeling lost in a sea of interview questions? Landed that dream interview for Fork Lift Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Fork Lift Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

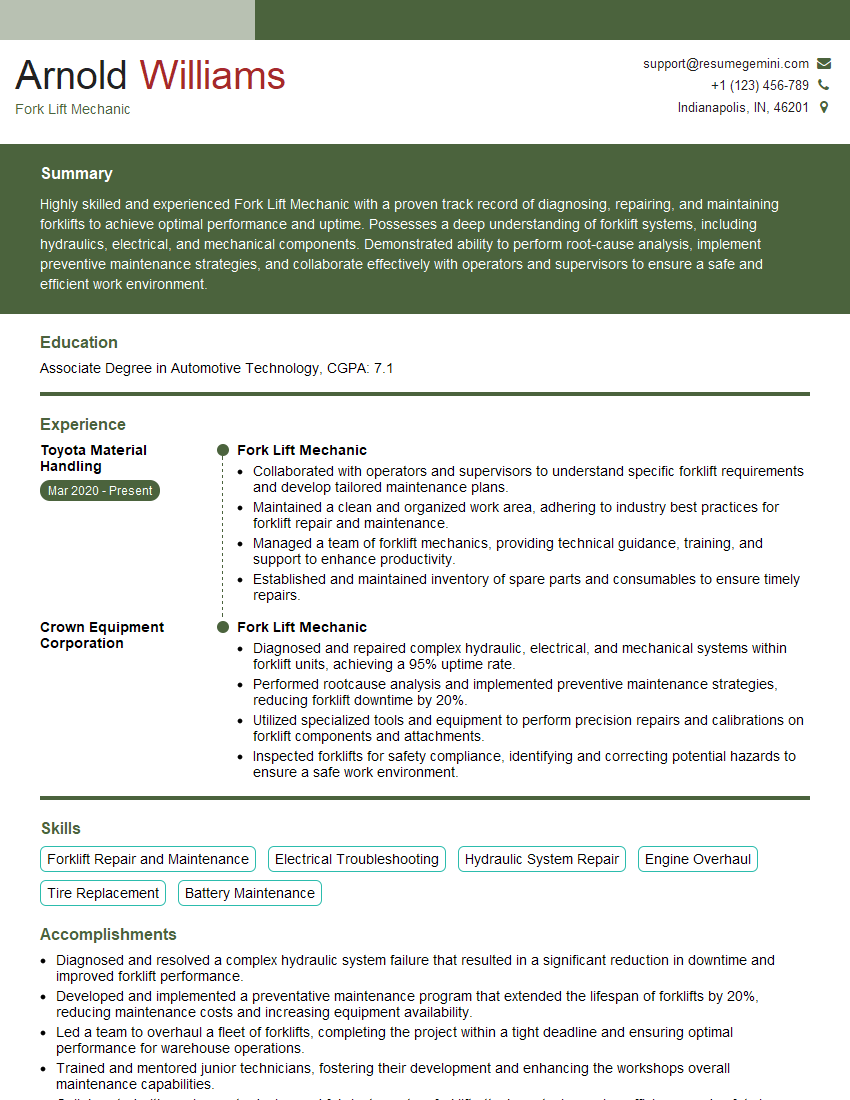

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fork Lift Mechanic

1. What are the different types of forklifts and their uses?

There are many different types of forklifts, each with its own unique purpose. Some of the most common types include:

- Electric forklifts: These forklifts are powered by an electric battery and are ideal for indoor use, as they produce no emissions.

- Diesel forklifts: These forklifts are powered by a diesel engine and are ideal for outdoor use, as they can handle rough terrain and heavy loads.

- Gasoline forklifts: These forklifts are powered by a gasoline engine and are also ideal for outdoor use, as they offer good fuel efficiency.

- Rough terrain forklifts: These forklifts are designed to handle rough terrain and are often used in construction and mining applications.

2. What are the key components of a forklift and their functions?

The key components of a forklift include:

- The chassis: This is the main frame of the forklift and provides support for the other components.

- The powertrain: This consists of the engine, transmission, and drivetrain, and provides power to the forklift.

- The hydraulic system: This consists of the hydraulic pump, valves, and cylinders, and provides power to the forklift’s lifting and steering functions.

- The mast: This is the vertical structure that supports the forks and allows the forklift to lift and lower loads.

- The forks: These are the attachments that are used to lift and transport loads.

3. What are the common causes of forklift accidents and how can they be prevented?

Some of the most common causes of forklift accidents include:

- Operator error: This is the most common cause of forklift accidents and can be prevented through proper training and supervision.

- Mechanical failure: This can be prevented through regular maintenance and inspections.

- Environmental factors: These include slippery surfaces, poor visibility, and congested areas, and can be prevented through proper planning and risk assessment.

4. What are the proper procedures for operating a forklift safely?

The proper procedures for operating a forklift safely include:

- Inspecting the forklift before each use

- Wearing appropriate safety gear

- Operating the forklift at a safe speed

- Avoiding overloading the forklift

- Using the forks properly

5. What are the different types of forklift attachments and their uses?

There are many different types of forklift attachments available, each with its own unique purpose. Some of the most common types include:

- Fork extensions: These extend the length of the forks and are used to handle long or awkward loads.

- Fork positioners: These allow the forks to be positioned at different angles and are used to handle loads that are not square or symmetrical.

- Sideshifters: These allow the forks to be shifted from side to side and are used to handle loads that need to be positioned precisely.

- Clamps: These are used to lift and transport loads that cannot be handled by forks, such as barrels or boxes.

6. What are the steps involved in troubleshooting a forklift?

The steps involved in troubleshooting a forklift include:

- Identifying the problem

- Gathering information

- Analyzing the information

- Developing a solution

- Implementing the solution

7. What are the different types of welding processes used on forklifts?

The different types of welding processes used on forklifts include:

- MIG welding: This is a semi-automatic welding process that uses a continuously fed wire electrode.

- TIG welding: This is a manual welding process that uses a non-consumable tungsten electrode.

- Stick welding: This is a manual welding process that uses a consumable stick electrode.

8. What are the safety precautions that should be taken when working on a forklift?

The safety precautions that should be taken when working on a forklift include:

- Disconnecting the battery

- Blocking the wheels

- Using proper tools and equipment

- Wearing appropriate safety gear

9. What are the different types of maintenance that should be performed on a forklift?

The different types of maintenance that should be performed on a forklift include:

- Daily maintenance: This includes tasks such as checking the fluid levels, inspecting the tires, and cleaning the forklift.

- Weekly maintenance: This includes tasks such as greasing the bearings, checking the brakes, and inspecting the hydraulic system.

- Monthly maintenance: This includes tasks such as changing the oil, filter, and spark plugs.

- Annual maintenance: This includes tasks such as a thorough inspection of the forklift, and any necessary repairs.

10. What are the different types of training that a forklift mechanic should have?

The different types of training that a forklift mechanic should have include:

- Forklift operation training

- Forklift maintenance training

- Forklift repair training

- Forklift safety training

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fork Lift Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fork Lift Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fork Lift Mechanics are specialists responsible for maintaining and repairing fork lifts, ensuring optimal performance and safety within a warehouse or industrial setting. Their duties encompass a wide range of tasks, including:

1. Maintenance and Inspection

Conduct regular inspections and preventative maintenance on fork lifts to identify potential issues and prevent breakdowns.

- Check and replace fluids, filters, belts, and other components.

- Inspect tires, brakes, and steering systems for wear and damage.

2. Troubleshooting and Repair

Diagnose and repair malfunctioning fork lifts, identifying and resolving mechanical or electrical problems.

- Use diagnostic tools to identify faulty components.

- Replace worn or damaged parts.

- Repair or calibrate hydraulic, electrical, and mechanical systems.

3. Electrical System Maintenance

Maintain and repair electrical systems in fork lifts, ensuring proper functionality and preventing electrical hazards.

- Inspect and test electrical wiring, fuses, and circuits.

- Troubleshoot and repair electrical faults.

- Replace or repair batteries and battery chargers.

4. Hydraulic System Maintenance

Maintain and repair hydraulic systems in fork lifts, ensuring smooth operation and preventing leaks or failures.

- Inspect and replace hydraulic hoses, pumps, and cylinders.

- Adjust hydraulic pressure and flow rates.

- Troubleshoot and repair hydraulic leaks or malfunctions.

Interview Tips

Preparing for an interview for a Fork Lift Mechanic position requires a combination of technical knowledge, industry-specific experience, and a well-crafted approach to the interview process.

1. Research the Company and Position

Thoroughly research the company you’re applying to and the specific Fork Lift Mechanic position. Understanding their operations, industry, and the responsibilities of the role will help you align your answers with their needs.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in fork lift maintenance and repair. Quantify your accomplishments using specific examples and metrics whenever possible.

- Describe your expertise in diagnosing and repairing electrical, hydraulic, and mechanical systems.

- Provide examples of successful troubleshooting and repair projects.

- Highlight your knowledge of fork lift safety regulations and industry best practices.

3. Demonstrate Problem-Solving Abilities

Fork Lift Mechanics need strong problem-solving skills. Use the STAR method (Situation, Task, Action, Result) to provide examples of how you have successfully diagnosed and resolved complex fork lift issues.

- Describe a situation where you encountered a challenging fork lift malfunction.

- Explain the steps you took to troubleshoot and diagnose the problem.

- Detail the actions you took to repair or resolve the issue.

- Quantify the results of your efforts, such as reduced downtime or increased productivity.

4. Prepare Industry-Specific Questions

Asking thoughtful questions about the company’s fork lift fleet, maintenance protocols, and industry trends shows your interest and enthusiasm for the role. This also gives you an opportunity to assess if the company is a good fit for your skills and career goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fork Lift Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!