Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gas Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

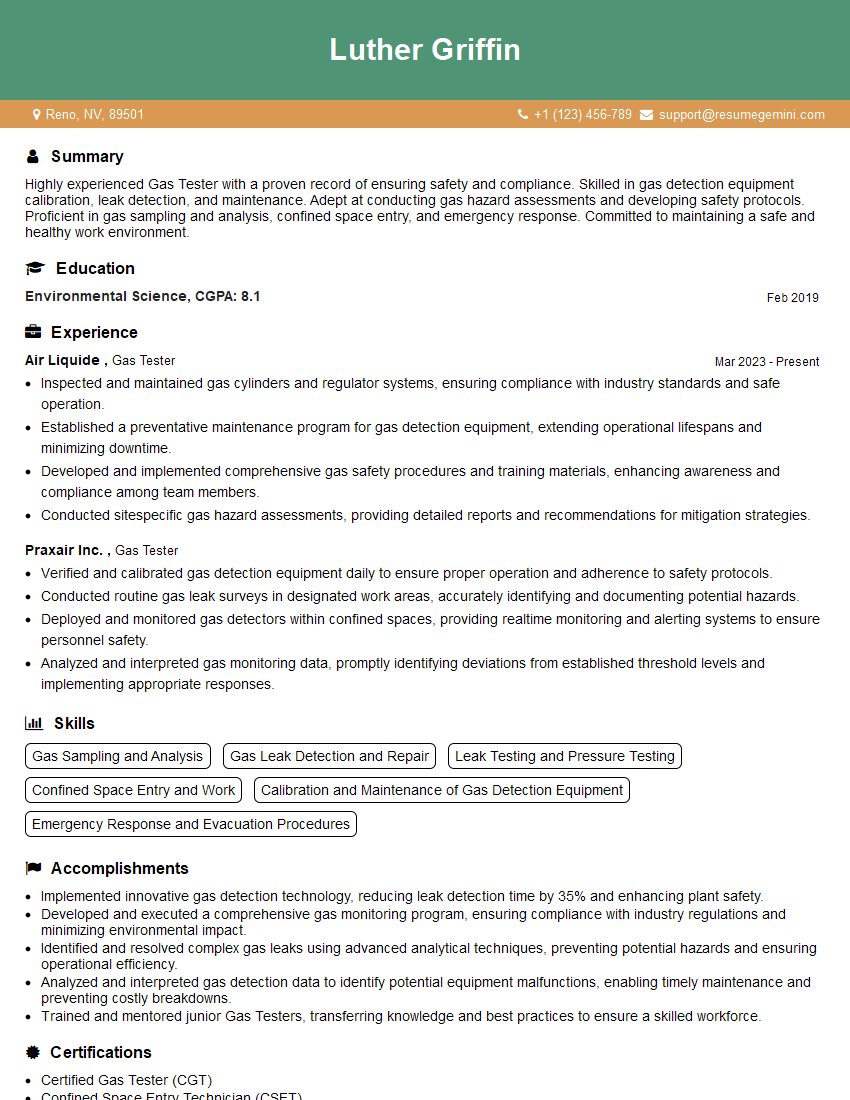

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Tester

1. Describe the different types of gas detectors and their applications in various industries?

Gas detectors are used in various industries to monitor and detect the presence of hazardous gases. The type of gas detector used depends on the specific gas being monitored and the application.

- Combustible gas detectors: These detectors are used to detect the presence of combustible gases, such as methane, propane, and butane. They are commonly used in industries such as oil and gas, manufacturing, and food processing.

- Toxic gas detectors: These detectors are used to detect the presence of toxic gases, such as carbon monoxide, hydrogen sulfide, and chlorine. They are commonly used in industries such as chemical manufacturing, mining, and wastewater treatment.

- Oxygen detectors: These detectors are used to measure the concentration of oxygen in an environment. They are commonly used in industries such as healthcare, manufacturing, and aviation.

2. Explain the principles of operation of electrochemical gas sensors?

Principle of Operation:

- Electrochemical gas sensors operate on the principle of electrochemistry, where a chemical reaction between the target gas and the sensor’s electrode generates an electrical signal.

- The sensor consists of two electrodes immersed in an electrolyte solution.

- When the target gas diffuses into the sensor, it reacts with the electrode surface, causing a change in the electrical potential between the electrodes.

- This change in potential is measured and converted into a gas concentration reading.

Types of Electrochemical Gas Sensors:

- Amperometric sensors: Measure the current generated by the electrochemical reaction.

- Potentiometric sensors: Measure the voltage generated by the electrochemical reaction.

- Conductometric sensors: Measure the change in conductivity of the electrolyte solution caused by the electrochemical reaction.

3. Describe the calibration procedure for a gas detector and the importance of regular calibration?

Calibration involves exposing the gas detector to known concentrations of the target gas and adjusting the detector’s output to accurately reflect these concentrations.

- Importance of Regular Calibration:

- Ensures the accuracy and reliability of the gas detector’s readings.

- Complies with industry regulations and safety standards.

- Minimizes false alarms and helps prevent accidents.

- Calibration Procedure:

- Use certified calibration gas with known concentrations.

- Expose the gas detector to the calibration gas.

- Adjust the detector’s output using calibration software or controls.

- Verify the calibration by exposing the detector to a different concentration of the calibration gas.

4. Explain the techniques used for sampling and analyzing gas samples for gas chromatography?

Sampling:

- Grab sampling: Collecting a single sample at a specific time.

- Integrated sampling: Collecting a sample over a period of time using a sampler.

- Direct sampling: Sampling the gas directly from the source.

Analysis:

- Gas chromatography (GC): Separates and analyzes the components of a gas sample based on their boiling points.

- Mass spectrometry (MS): Identifies and quantifies the components of a gas sample based on their mass-to-charge ratio.

- Flame ionization detector (FID): Detects and quantifies organic compounds in a gas sample based on their ability to ionize in a flame.

5. Describe the different types of personal protective equipment (PPE) used for gas testing and the importance of proper PPE selection?

The type of PPE used depends on the specific hazards associated with the gas testing environment.

- Respirators: Protect the wearer from inhaling hazardous gases.

- Gloves: Protect the wearer’s hands from contact with hazardous gases.

- Eye protection: Protects the wearer’s eyes from contact with hazardous gases.

- Coveralls: Protect the wearer’s skin from contact with hazardous gases.

- Safety boots: Protect the wearer’s feet from potential hazards.

6. Explain the importance of maintaining records of gas testing results and how these records can be used?

Records of gas testing results are essential for several reasons:

- Legal compliance: Meeting regulatory requirements and providing evidence of compliance.

- Safety management: Identifying trends and patterns in gas levels to assess risks and implement preventive measures.

- Quality assurance: Ensuring that gas testing is performed accurately and consistently.

- Troubleshooting: Identifying the source of gas leaks or elevated gas levels.

- Training and education: Providing data for training programs and informing workers about potential gas hazards.

7. Describe the different types of gas detection systems and their applications in various industries?

- Fixed gas detection systems: Permanently installed in an area to continuously monitor gas levels.

- Portable gas detection systems: Handheld or wearable devices used for periodic monitoring or emergency response.

- Wireless gas detection systems: Transmit data wirelessly to a central monitoring system.

Applications:

- Industrial settings (e.g., chemical plants, refineries)

- Commercial buildings (e.g., hospitals, schools)

- Residential settings (e.g., homes with natural gas appliances)

8. Explain the principles of infrared spectroscopy and its applications in gas analysis?

Infrared spectroscopy involves analyzing the absorption or emission of infrared radiation by gas molecules.

- Principle: Gas molecules absorb infrared radiation at specific wavelengths, corresponding to the vibrational modes of the molecule.

- Applications:

- Identifying and quantifying gas components

- Monitoring gas concentrations in various environments

9. Describe the different types of gas sampling probes and the factors to consider when selecting the appropriate probe?

- Types:

- Open-path probes: Measure gas concentrations over a distance.

- Closed-path probes: Measure gas concentrations in a confined space or sample line.

- Selection Factors:

- Gas type being measured

- Measurement environment

- Required accuracy and sensitivity

10. Explain the role of data loggers in gas monitoring systems and how they are used to analyze and manage gas data?

- Role: Collect and store gas concentration data over time.

- How they are used:

- Provide continuous monitoring and historical data

- Generate alarms and notifications based on preset thresholds

- Assist in identifying trends and patterns in gas levels

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gas Testers play a crucial role in ensuring safety and compliance in industries handling gases. Their primary responsibilities include:

1. Gas Detection and Monitoring

Conducting regular gas detection surveys to identify and measure the presence of hazardous gases in various workplace environments.

- Operating and maintaining gas detection equipment to monitor gas levels, including portable and fixed systems.

- Interpreting gas readings and identifying potential hazards to personnel and equipment.

2. Hazard Assessment and Mitigation

Assessing potential gas hazards associated with workplace processes, equipment, and materials.

- Developing and implementing gas control measures, such as ventilation, containment, and personal protective equipment (PPE).

- Conducting inspections and audits to ensure adherence to gas safety protocols and regulations.

3. Emergency Response and Coordination

Responding to gas emergencies, including leaks, spills, and fires.

- Evacuating personnel from affected areas and implementing emergency response plans.

- Coordinating with emergency services, such as fire departments and hazardous materials teams.

4. Documentation and Reporting

Maintaining accurate records of gas detection surveys, hazard assessments, and emergency responses.

- Preparing reports on gas safety compliance and recommending improvements.

- Providing technical guidance and training to employees on gas safety practices.

Interview Tips

To ace an interview for a Gas Tester position, it’s essential to demonstrate a combination of technical expertise, safety awareness, and communication skills. Here are some tips to prepare:

1. Research the Industry

Familiarize yourself with the specific industry or facility where you’re applying. Research common gases used, potential hazards, and industry best practices.

- Visit the company website to understand their operations and safety policies.

- Network with professionals in the field through industry events or LinkedIn.

2. Highlight Relevant Experience

Emphasize your experience in gas detection, hazard assessment, and emergency response. Provide specific examples of your work, quantifying your accomplishments whenever possible.

- Discuss your proficiency in operating and maintaining various gas detection equipment.

- Share examples of how you have successfully identified and mitigated gas hazards.

3. Demonstrate Safety Awareness

Showcase your thorough understanding of gas safety regulations and industry best practices. Explain how you prioritize safety in your work.

- Highlight your knowledge of safe work practices, emergency procedures, and PPE guidelines.

- Explain how you stay up-to-date with industry developments and emerging technologies.

4. Practice Communication Skills

Gas Testers often need to communicate technical information to both technical and non-technical audiences. Practice articulating your findings clearly and concisely.

- Prepare examples of how you have effectively presented gas safety reports or provided training to employees.

- Demonstrate your ability to listen attentively and address concerns professionally.

5. Prepare Questions

Asking thoughtful questions during the interview shows that you are engaged and interested in the position. Prepare questions about the company’s gas safety culture, training opportunities, and career growth potential.

Next Step:

Now that you’re armed with the knowledge of Gas Tester interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Gas Tester positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini