Are you gearing up for a career in Tipple Mechanic? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tipple Mechanic and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

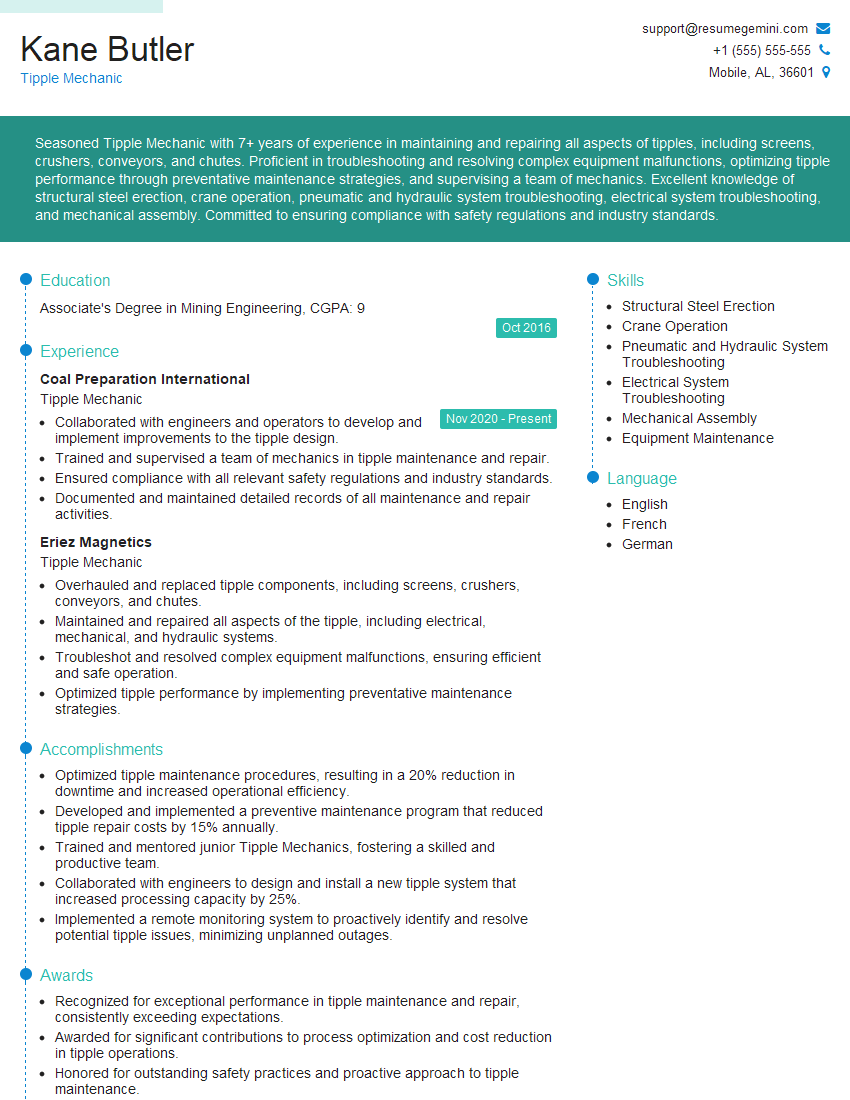

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tipple Mechanic

1. What are the main responsibilities of a Tipple Mechanic?

As a Tipple Mechanic, my primary responsibilities include:

- Inspecting, maintaining, and repairing tipple equipment, including conveyors, screens, and crushers

- Troubleshooting and diagnosing mechanical and electrical problems

- Performing lubrication, adjustments, and other preventative maintenance tasks

- Working with other maintenance personnel to ensure smooth and efficient operation

- Adhering to safety regulations and maintaining a safe work environment

2. What is your experience in troubleshooting and repairing tipple equipment?

Electrical Troubleshooting

- Diagnosed electrical faults using multimeters and other test equipment

- Repaired and replaced electrical components, such as switches, motors, and sensors

- Troubleshooted wiring issues and ensured proper electrical connections

Mechanical Troubleshooting

- Inspected and diagnosed mechanical failures in conveyors, screens, and crushers

- Disassembled and reassembled equipment to repair or replace damaged components

- Adjusted and calibrated equipment to optimize performance

3. Describe your knowledge of conveyor systems and their maintenance.

- Familiar with different types of conveyors, including belt, chain, and screw conveyors

- Inspected conveyor components such as belts, rollers, and idlers

- Performed routine maintenance tasks such as belt tensioning, roller lubrication, and cleaning

- Troubleshooted and repaired conveyor problems, such as belt slippage, material buildup, and electrical issues

4. What are your experience with hydraulic systems?

- Inspected and maintained hydraulic components such as pumps, valves, and cylinders

- Diagnosed and repaired hydraulic leaks, pressure issues, and other malfunctions

- Replaced hydraulic hoses, filters, and other components

- Ensured proper hydraulic fluid levels and cleanliness

5. How do you prioritize maintenance tasks and manage your time effectively?

- Assessed the importance and urgency of different tasks

- Created and followed a maintenance schedule

- Delegated tasks to other team members when necessary

- Used downtime to perform preventive maintenance and inspections

- Communicated regularly with supervisors to keep them informed of maintenance progress

6. Describe your experience with safety procedures and regulations.

- Familiar with industry safety standards and regulations

- Adhered to proper lockout/tagout procedures

- Wore appropriate personal protective equipment (PPE)

- Conducted regular safety inspections and reported any hazards

- Maintained a clean and organized work environment

7. What is your experience with working in a team environment?

- Collaborated with other mechanics and maintenance personnel

- Shared knowledge and expertise with team members

- Assisted with training and development of new team members

- Worked effectively under the supervision of a lead mechanic

- Contributed to a positive and productive team atmosphere

8. How do you stay updated on the latest technology and advancements in the field?

- Attended industry conferences and workshops

- Read trade publications and technical journals

- Participated in online forums and discussion groups

- Consulted with equipment manufacturers and vendors

- Explored new technologies and innovations to improve maintenance practices

9. What is your availability?

I am available to work flexible hours, including weekends and holidays, as needed to meet the demands of the job. I am also willing to travel for extended periods if required.

10. Why are you interested in this position?

I am eager to join your team as a Tipple Mechanic because I am passionate about maintaining and repairing heavy equipment. I am confident in my abilities to contribute to the smooth and efficient operation of your tipple. I am also eager to learn from experienced mechanics and expand my knowledge and skills in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tipple Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tipple Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tipple Mechanics are responsible for maintaining and repairing the mechanical systems of a tipple, which is a facility that processes coal and other materials. Some of the key responsibilities of a Tipple Mechanic may include:

1. Maintain and Repair Mechanical Systems

Tipple Mechanics are responsible for inspecting, maintaining, and repairing a variety of mechanical systems within a tipple. This includes equipment such as conveyors, crushers, screens, and feeders.

- Identify problems with mechanical systems and perform necessary repairs.

- Inspect and maintain equipment to prevent breakdowns and ensure smooth operation.

2. Troubleshooting Electrical Systems

Tipple Mechanics may also be responsible for troubleshooting and repairing electrical systems within a tipple.

- Troubleshoot and repair electrical faults to ensure safe and efficient operation.

- Monitor electrical systems and take corrective actions to prevent electrical hazards.

3. Inspect and Maintain Equipment

Tipple Mechanics are responsible for inspecting and maintaining a variety of equipment within a tipple.

- Inspect and maintain equipment to ensure proper operation and prevent breakdowns.

- Replace worn or damaged parts to keep equipment in good working order.

4. Safety and Compliance

Tipple Mechanics are responsible for ensuring that all work is done in a safe and compliant manner.

- Follow safety protocols and guidelines to prevent accidents and injuries.

- Ensure that all work meets industry standards and regulations.

Interview Tips

Here are some tips and hacks to help you ace your Tipple Mechanic interview:

1. Practice Your Answers

Before the interview, take time to research common Tipple Mechanic interview questions and practice your answers. This will help you feel more confident and articulate during the interview.

2. Highlight Your Experience and Skills

Be sure to highlight your relevant experience and skills in your resume and during the interview. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

3. Show Your Knowledge of the Industry

Research the coal mining industry and the specific company you’re interviewing with. This will show the interviewer that you’re knowledgeable about the field and interested in the position.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are passionate about their work. Show your enthusiasm for the role and the company, and maintain a positive attitude throughout the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tipple Mechanic role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.