Feeling lost in a sea of interview questions? Landed that dream interview for Repairer, Engine, Production but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Repairer, Engine, Production interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

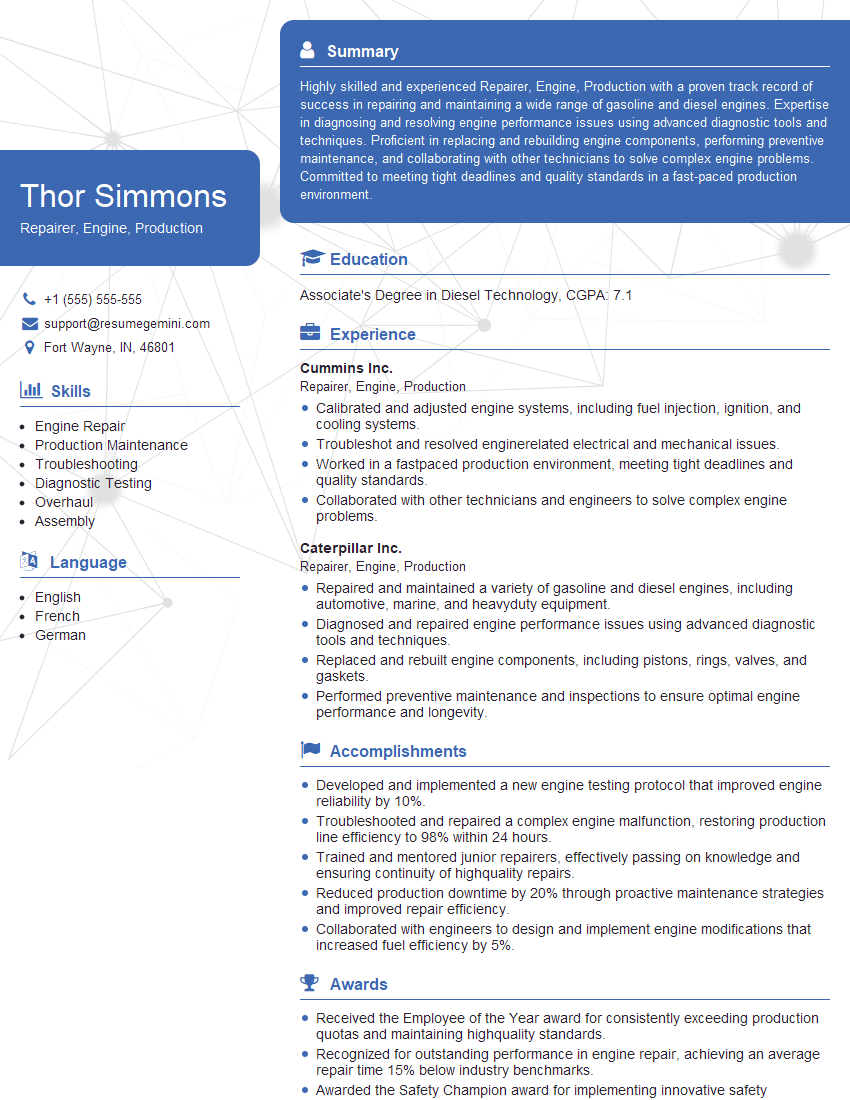

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Repairer, Engine, Production

1. Describe the major components of a reciprocating engine and their functions?

- Cylinder: It is a cylindrical chamber where the piston moves reciprocally and combustion takes place.

- Piston: It is a cylindrical-shaped component that moves up and down within the cylinder, converting reciprocating motion into rotary motion.

- Piston Rings: These rings seal the combustion chamber by forming a tight fit between the piston and cylinder wall.

- Connecting Rod: It connects the piston to the crankshaft, transmitting the reciprocating motion to the rotary motion.

- Crankshaft: It converts the reciprocating motion of the piston into rotary motion, transmitting power to the output shaft.

- Camshaft: It controls the timing of valve operation, opening and closing the intake and exhaust valves.

- Valves: These are used to control the flow of air and fuel into the cylinder and the exhaust gases out of the cylinder.

- Cylinder Head: It forms the top cover of the cylinder, enclosing the combustion chamber and housing the valves.

2. Explain the working principle of a 4-stroke engine?

Intake Stroke

- Intake valve opens.

- Piston moves down, creating a vacuum.

- Air and fuel mixture is drawn into the cylinder.

Compression Stroke

- Both valves are closed.

- Piston moves up, compressing the air and fuel mixture.

Power Stroke

- Spark plug ignites the compressed mixture.

- Expansion of gases drives the piston down.

Exhaust Stroke

- Exhaust valve opens.

- Piston moves up, pushing the exhaust gases out.

- Exhaust valve closes.

3. How do you troubleshoot a diesel engine that is not starting?

- Check fuel supply and fuel filter.

- Inspect glow plugs or starter motor.

- Examine battery and electrical connections.

- Verify compression and air intake.

- Diagnose engine control unit and sensors.

- Troubleshoot turbocharger and intercooler.

4. How do you align an engine to a generator?

- Use a laser alignment tool or dial gauge.

- Position the engine and generator on a flat surface.

- Center the laser beam or dial gauge on the shafts.

- Adjust the engine or generator position until the shafts are perfectly aligned.

- Tighten the mounting bolts to secure the alignment.

5. What are the common causes of engine overheating?

- Coolant leak.

- Faulty water pump.

- Clogged radiator.

- Malfunctioning thermostat.

- Low coolant level.

- Air in the cooling system.

- Overloading the engine.

6. How do you diagnose and repair a hydraulic leak in an engine?

- Identify the source of the leak: Use a flashlight and visually inspect all hydraulic lines, hoses, and fittings.

- Inspect for loose or damaged connections: Tighten any loose fittings and replace damaged ones.

- Examine hoses and lines for cracks or wear: Replace any damaged or worn hoses and lines.

- Check for leaky seals: Replace any worn or damaged seals to prevent further leaks.

- Use a pressure gauge to identify leaks: Connect a pressure gauge to the hydraulic system and observe the pressure drop to identify the location of the leak.

7. Describe the different types of engine lubricants and their applications?

- Mineral Oils: Derived from crude oil, suitable for older engines.

- Synthetic Oils: Engineered oils with improved performance, suited for high-performance engines.

- Semi-Synthetic Oils: Blend of mineral and synthetic oils, offering a balance of performance and cost.

- Multi-Grade Oils: Can withstand a wide range of temperatures, providing optimal lubrication across different operating conditions.

- Diesel Engine Oils: Specifically formulated for diesel engines, with additives to withstand higher pressures and temperatures.

8. How do you measure and adjust the valve clearance on an engine?

- Locate the valve clearance specifications: Refer to the engine’s service manual for the specific clearance values.

- Use feeler gauges: Insert a feeler gauge between the valve stem and rocker arm or camshaft lobe.

- Adjust the clearance: If the clearance is incorrect, loosen the locknut and turn the adjusting screw to achieve the specified clearance.

- Retighten the locknut: Once the clearance is adjusted, retighten the locknut to secure the setting.

9. What are the safety precautions to follow when working on engines?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Ensure the engine is turned off and cooled down before performing any work.

- Disconnect the battery terminals to prevent electrical shocks.

- Be aware of rotating parts and avoid loose clothing that could get caught.

- Use proper lifting techniques to prevent injuries.

- Do not smoke or have open flames near the engine.

- Have a fire extinguisher nearby in case of emergencies.

10. Describe the different types of fuel injection systems and their advantages and disadvantages?

-

Port Fuel Injection (PFI):

- Fuel is injected directly into the intake ports.

- Advantages: Precise fuel metering, improved fuel efficiency.

- Disadvantages: Can lead to carbon buildup on intake valves. Direct Fuel Injection (DFI):

- Fuel is injected directly into the combustion chamber.

- Advantages: Better fuel atomization, increased power and torque.

- Disadvantages: Higher cost, more complex maintenance. Common Rail Injection (CRI):

- Fuel is stored in a common rail at high pressure and injected into the cylinders.

- Advantages: Highly precise injection timing and pressure control.

- Disadvantages: Expensive and requires specialized equipment for maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Repairer, Engine, Production.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Repairer, Engine, Production‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Repairer, Engine, Production is responsible for repairing and maintaining engines used in production processes. They work in collaboration with engineering and maintenance teams to ensure that engines are operating at optimal performance levels.

1. Engine Repair and Maintenance

Performing diagnostics and troubleshooting to identify engine issues, including mechanical, electrical, and computer-related problems

- Disassembling, inspecting, and repairing engines and engine components.

- Performing scheduled maintenance and overhauls to prevent engine breakdowns.

2. Equipment Troubleshooting

Identifying and resolving issues related to engine-driven equipment, such as generators, pumps, and compressors.

- Using diagnostic tools to troubleshoot and repair equipment malfunctions.

- Testing and calibrating equipment to ensure accuracy and reliability.

3. Collaboration and Communication

Working closely with production teams to diagnose and resolve engine-related issues.

- Communicating with maintenance personnel and engineers to coordinate repairs and maintenance activities.

- Providing technical support and guidance to production staff on engine operation and maintenance.

4. Recordkeeping and Documentation

Maintaining accurate records of engine repairs and maintenance activities.

- Documenting engine performance data and maintenance history.

- Tracking inventory and ordering replacement parts.

Interview Tips

Preparing for an interview for a Repairer, Engine, Production position requires thorough research, practice, and a deep understanding of the job responsibilities. Here are some tips to help you ace the interview:

1. Research the Company and Position

Research the company’s industry, products, and services. This will help you understand the context of the role and tailor your answers accordingly.

- Visit the company website and social media pages to gather information about their culture and values.

- Read industry publications and news articles to stay up-to-date on the latest trends and technologies.

2. Highlight Relevant Skills and Experience

Showcase your skills and experience that are directly relevant to the job responsibilities. Provide specific examples of your accomplishments and how they demonstrate your competence.

- Quantify your achievements whenever possible using specific metrics or data.

- Be prepared to discuss your experience in engine repair, troubleshooting, and equipment maintenance.

3. Prepare for Technical Questions

Expect technical questions related to engine operation, repair, and troubleshooting. Brush up on your knowledge of engine components, diagnostic techniques, and common engine problems.

- Practice answering questions about engine diagnostics, troubleshooting procedures, and repair techniques.

- Be prepared to discuss your experience with specific types of engines or equipment.

4. Demonstrate Problem-Solving Abilities

Repairer, Engine, Production requires strong problem-solving abilities. Provide examples of how you have identified and resolved engine-related issues in the past.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Describe the problem you faced, the actions you took to resolve it, and the positive outcomes.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Repairer, Engine, Production interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!