Feeling lost in a sea of interview questions? Landed that dream interview for Control Valve Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Control Valve Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

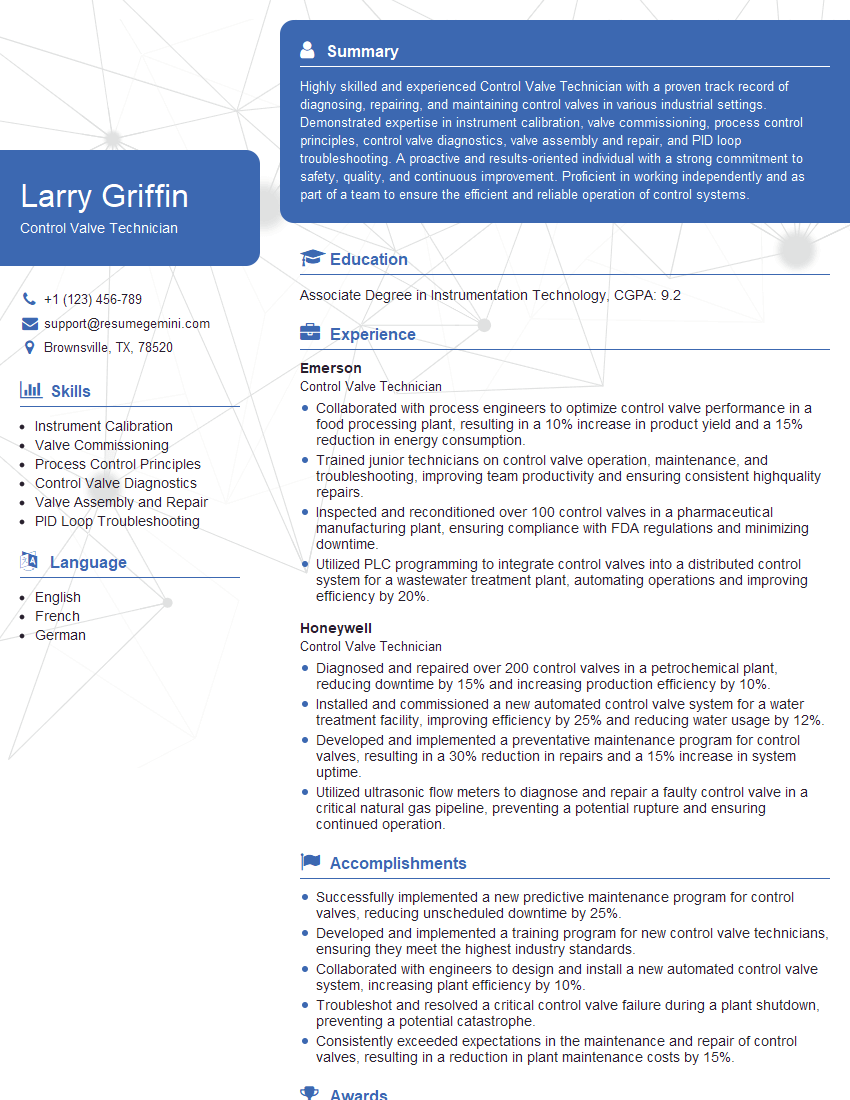

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Control Valve Technician

1. Describe the different types of control valves and their applications.

- Globe valves are used for throttling or on/off applications. They have a spherical plug that moves up and down within a cylindrical body.

- Ball valves are used for on/off applications. They have a ball with a hole through it that rotates 90 degrees to block or allow flow.

- Butterfly valves are used for throttling or on/off applications. They have a circular disk that rotates to block or allow flow.

- Diaphragm valves are used for throttling or on/off applications. They have a diaphragm that moves up and down to block or allow flow.

- Pinch valves are used for throttling or on/off applications. They have a sleeve that pinches off the flow path.

2. What are the key performance characteristics of a control valve?

Flow capacity

- The flow capacity of a control valve is the maximum amount of fluid that it can pass through at a given pressure drop.

- The flow capacity is determined by the size of the valve body, the type of valve, and the valve’s trim.

Rangeability

- The rangeability of a control valve is the ratio of the maximum flow rate to the minimum flow rate that it can control.

- The rangeability is determined by the type of valve and the valve’s trim.

Accuracy

- The accuracy of a control valve is the degree to which it can control the flow rate of the fluid.

- The accuracy is determined by the type of valve, the valve’s trim, and the valve’s controller.

3. What are the different types of valve positioners?

- Pneumatic positioners use compressed air to move the valve stem.

- Electromechanical positioners use an electric motor to move the valve stem.

- Electrohydraulic positioners use hydraulic pressure to move the valve stem.

4. What are the advantages and disadvantages of each type of valve positioner?

Pneumatic positioners

Advantages

- Simple and reliable

- Low cost

- Capable of handling high pressures

Disadvantages

- Can be slow and inaccurate

- Require a source of compressed air

Electromechanical positioners

Advantages

- Fast and accurate

- Can be used in hazardous areas

- Can be easily integrated with other control systems

Disadvantages

- More expensive than pneumatic positioners

- Can be affected by electrical noise

Electrohydraulic positioners

Advantages

- Fast and accurate

- Can handle high pressures

- Can be used in hazardous areas

Disadvantages

- More expensive than pneumatic and electromechanical positioners

- Require a source of hydraulic pressure

5. How do you troubleshoot a control valve that is not working properly?

- Check the power supply to the valve.

- Check the valve’s input signal.

- Check the valve’s output signal.

- Check the valve’s position.

- Check the valve’s trim.

- Check the valve’s packing.

6. What are the safety precautions that must be taken when working on control valves?

- Isolating the valve from the process

- Releasing the pressure from the valve

- Venting the valve to the atmosphere

- Wearing appropriate personal protective equipment

7. What are the different types of control valve sizing methods?

- Equal percentage

- Linear

- Quick opening

- Modified equal percentage

8. What is the difference between a control valve and a regulating valve?

- Control valves are used to control the flow rate of a fluid.

- Regulating valves are used to maintain a constant pressure or flow rate.

9. What are the different types of control valve actuators?

- Diaphragm actuators

- Piston actuators

- Rotary actuators

10. What are the advantages and disadvantages of each type of control valve actuator?

Diaphragm actuators

Advantages

- Simple and reliable

- Low cost

- Capable of handling high pressures

Disadvantages

- Can be slow

- Can be affected by temperature changes

Piston actuators

Advantages

- Fast and accurate

- Can handle high pressures

- Can be used in hazardous areas

Disadvantages

- More expensive than diaphragm actuators

- Can be complex to install and maintain

Rotary actuators

Advantages

- Fast and accurate

- Can handle high torques

- Can be used in hazardous areas

Disadvantages

- More expensive than diaphragm and piston actuators

- Can be complex to install and maintain

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Control Valve Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Control Valve Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Control Valve Technicians are responsible for the maintenance, repair, and calibration of control valves in industrial settings. They ensure that valves are functioning properly to regulate flow rates and pressures within systems.

1. Maintenance and Repair

Inspect and test control valves to identify any issues or malfunctions.

- Repair or replace defective components, such as diaphragms, springs, and actuators.

- Lubricate and adjust valves to ensure smooth operation.

2. Calibration

Use specialized equipment to calibrate control valves according to specifications.

- Adjust valve settings to achieve optimal flow rates and pressures.

- Ensure that valves meet industry standards and safety requirements.

3. Troubleshooting

Diagnose and resolve issues with control valves in a timely manner.

- Analyze system data and identify potential problems.

- Implement corrective actions to restore valve functionality.

4. Documentation

Maintain detailed records of valve maintenance, repairs, and calibrations.

- Provide documentation for troubleshooting and future reference.

- Comply with industry regulations and standards.

Interview Tips

Preparing for a Control Valve Technician interview can help you stand out from other candidates and increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Role

Research the company’s industry, products, and recent developments. Understand the specific responsibilities of the Control Valve Technician role and how it aligns with your qualifications and experience.

- Visit the company’s website and social media pages.

- Read industry publications and news articles to gain insights into their operations and challenges.

2. Highlight Your Technical Skills

Emphasize your proficiency in control valve maintenance, repair, and calibration techniques. Provide specific examples of projects where you successfully diagnosed and resolved issues with control valves.

- Quantify your accomplishments, for instance, by stating “Reduced valve downtime by 20% through proactive maintenance strategies.”

- Showcase your expertise in using calibration equipment and industry-standard testing procedures.

3. Demonstrate Your Problem-Solving Abilities

Control Valve Technicians need to be able to identify and solve problems quickly and efficiently. Share instances where you used logical reasoning and analytical skills to resolve complex valve issues.

- Explain how you approached the problem, identified potential causes, and implemented solutions.

- Use the STAR (Situation, Task, Action, Result) method to structure your responses.

4. Emphasize Safety and Compliance

Control Valve Technicians must prioritize safety and adhere to industry regulations. Highlight your commitment to maintaining a safe work environment and ensuring valve compliance.

- Mention any certifications or training programs you have completed in areas such as OSHA or valve safety.

- Describe your experience in conducting risk assessments and implementing safety protocols.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Control Valve Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Control Valve Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.