Are you gearing up for a career in Industrial Gas Servicer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Industrial Gas Servicer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

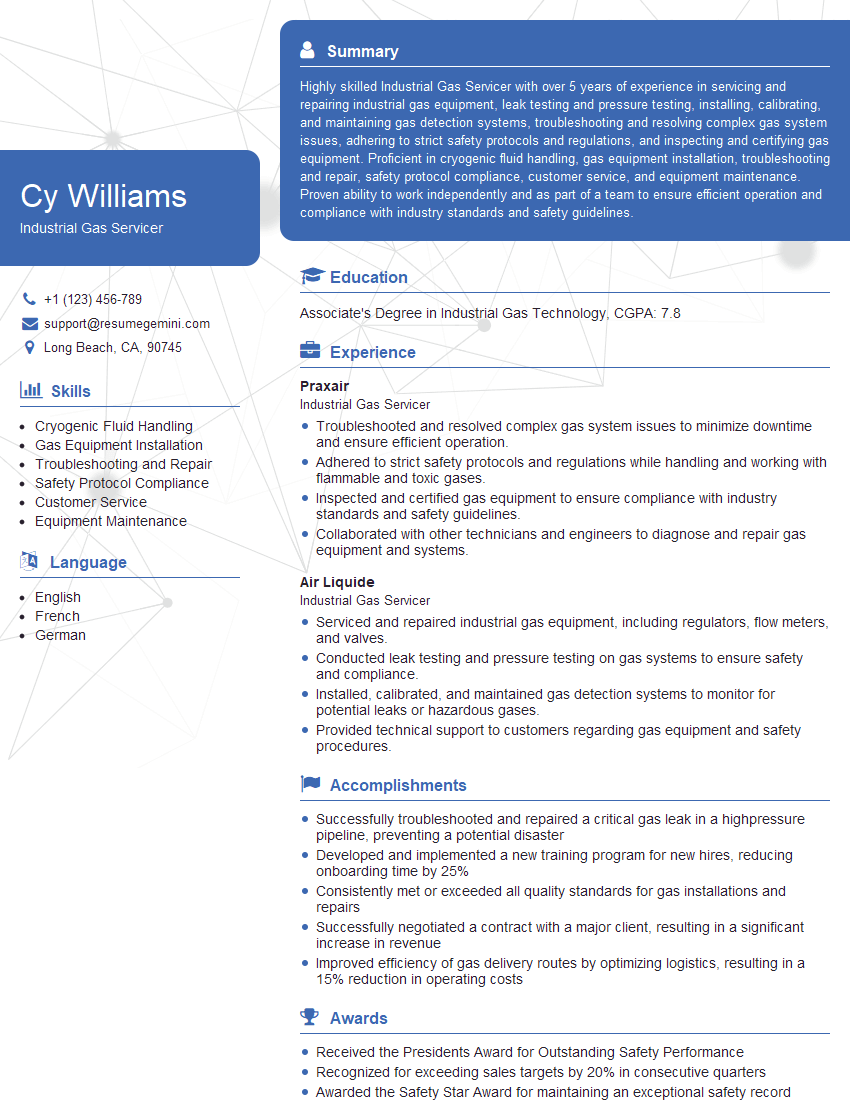

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Gas Servicer

1. Describe the principles of cryogenic gas handling and the safety precautions that must be taken when working with cryogenic liquids.

- Cryogenic liquids are liquids with temperatures below -150°C (-238°F).

- They are extremely cold and can cause severe burns if they come into contact with skin.

- Cryogenic liquids are also very volatile and can expand rapidly when they are released from their containers.

- This can create a risk of explosion if the liquid is not handled properly.

- When working with cryogenic liquids, it is important to wear proper protective clothing, including gloves, goggles, and a face shield.

- It is also important to use caution when transferring cryogenic liquids from one container to another.

2. What are the different types of industrial gases and what are their uses?

Inert gases

- Argon: Used in welding, metalworking, and food processing.

- Nitrogen: Used in food processing, pharmaceuticals, and electronics.

- Helium: Used in balloons, airships, and diving.

Reactive gases

- Oxygen: Used in welding, cutting, and medical applications.

- Hydrogen: Used in fuel cells, rocket propulsion, and chemical processing.

- Acetylene: Used in welding and cutting.

3. What are the different types of industrial gas cylinders and what are their markings?

- Type 1 cylinders: These are the most common type of industrial gas cylinder.

- They are made of steel and have a cylindrical shape.

- They are typically used to store and transport gases at pressures up to 3000 psi.

- Type 2 cylinders: These cylinders are similar to Type 1 cylinders, but they are made of aluminum.

- They are lighter than Type 1 cylinders, but they are not as strong.

- They are typically used to store and transport gases at pressures up to 2500 psi.

- Type 3 cylinders: These cylinders are made of composite materials, such as fiberglass or carbon fiber.

- They are lighter than Type 1 and Type 2 cylinders, and they are also more durable.

- They are typically used to store and transport gases at pressures up to 5000 psi.

4. What are the different types of industrial gas regulators and what are their functions?

- Single-stage regulators: These regulators are the simplest type of regulator.

- They have a single diaphragm that reduces the pressure of the gas as it flows from the cylinder to the outlet.

- Two-stage regulators: These regulators have two diaphragms.

- The first diaphragm reduces the pressure of the gas from the cylinder to a intermediate pressure.

- The second diaphragm then reduces the pressure of the gas from the intermediate pressure to the outlet pressure.

- Multi-stage regulators: These regulators have multiple diaphragms.

- They are used to reduce the pressure of the gas from the cylinder to a very low outlet pressure.

5. What are the different types of industrial gas flowmeters and what are their uses?

- Rotameters: These flowmeters are based on the principle of variable area.

- The gas flows through a tapered tube, and the float rises or falls depending on the flow rate.

- Orifice plates: These flowmeters are based on the principle of differential pressure.

- The gas flows through an orifice in a plate, and the pressure drop across the orifice is proportional to the flow rate.

- Turbine flowmeters: These flowmeters are based on the principle of electromagnetic induction.

- The gas flows through a turbine, and the speed of the turbine is proportional to the flow rate.

6. What are the different types of industrial gas welding torches and what are their uses?

- Oxy-fuel torches: These torches use a mixture of oxygen and fuel gas to produce a flame.

- They are used for welding, cutting, and heating.

- Plasma torches: These torches use a plasma arc to produce a flame.

- They are used for welding, cutting, and spraying.

- Laser torches: These torches use a laser beam to produce a flame.

- They are used for welding, cutting, and engraving.

7. What are the different types of industrial gas leak detection methods and what are their advantages and disadvantages?

- Soap bubble test: This is a simple and inexpensive method for detecting leaks.

- It involves applying a soap solution to the suspected leak area.

- If there is a leak, the soap solution will bubble.

- Electronic leak detector: This is a more sensitive method for detecting leaks.

- It uses an electronic sensor to detect the presence of gas.

- Ultrasonic leak detector: This is a non-invasive method for detecting leaks.

- It uses ultrasonic waves to detect the presence of gas.

8. What are the different types of industrial gas safety devices and what are their functions?

- Pressure relief valves: These valves are designed to relieve excessive pressure in a gas system.

- They are typically used to protect equipment from damage.

- Check valves: These valves are designed to prevent the flow of gas in the wrong direction.

- They are typically used to protect equipment from damage.

- Flame arrestors: These devices are designed to prevent the spread of flames from one part of a gas system to another.

- They are typically used to protect equipment from damage.

9. What are the different types of industrial gas storage and handling systems and what are their advantages and disadvantages?

- Cylinders: Cylinders are the most common type of gas storage system.

- They are portable and relatively inexpensive.

- However, they can be dangerous if they are not handled properly.

- Bulk tanks: Bulk tanks are used to store large quantities of gas.

- They are more expensive than cylinders, but they are also more convenient and safer.

- Gas generators: Gas generators are used to produce gas on-site.

- They are more expensive than cylinders or bulk tanks, but they can be more economical in the long run.

10. What are the latest trends in industrial gas technology?

- The use of new materials, such as carbon fiber and composites, to make lighter and stronger gas cylinders.

- The development of new gas regulators that are more accurate and reliable.

- The development of new gas flowmeters that are more accurate and versatile.

- The development of new gas welding torches that are more efficient and powerful.

- The development of new gas leak detection methods that are more sensitive and reliable.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Gas Servicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Gas Servicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial Gas Servicers are responsible for maintaining and repairing industrial gas systems, ensuring their safe and efficient operation. Some key job responsibilities include:

1. System Maintenance and Inspection

Regularly inspect gas systems, including cylinders, tanks, pipelines, and valves, to ensure they are in good working order and meet safety regulations.

- Identify potential hazards and take corrective actions to prevent accidents or leaks.

- Monitor gas pressure, flow rates, and other parameters to ensure optimal system performance.

2. Troubleshooting and Repairs

Diagnose and repair gas system issues quickly and efficiently, minimizing downtime and ensuring system reliability.

- Identify and fix leaks, replace faulty components, and perform necessary repairs.

- Collaborate with other technicians and engineers to resolve complex issues.

3. Installation and Commissioning

Install new gas systems or upgrade existing ones, ensuring proper functionality and compliance with industry standards.

- Follow blueprints and specifications to install gas lines, tanks, and other equipment.

- Commission systems, conduct pressure tests, and train operators on proper usage.

4. Safety and Compliance

Prioritize workplace safety and adhere to all relevant regulations and codes.

- Wear appropriate protective gear, follow lockout-tagout procedures, and maintain a clean and organized work area.

- Stay up-to-date on industry best practices and technological advancements related to gas systems.

Interview Tips

To ace an Industrial Gas Servicer interview, it’s essential to prepare thoroughly and showcase your skills and experience. Here are some interview tips and preparation strategies:

1. Research the Company and Role

Familiarize yourself with the company’s industry, values, and specific needs related to industrial gas services. Understand the key responsibilities of the role and how your qualifications align with them.

- Visit the company’s website and social media pages to gather information.

- Review industry publications and articles to stay updated on trends and best practices.

2. Highlight Your Technical Skills

Emphasize your knowledge and experience in industrial gas systems, including troubleshooting, repairs, and maintenance procedures. Quantify your accomplishments and provide specific examples to demonstrate your proficiency.

- Describe a complex gas system issue you resolved efficiently, highlighting your diagnostic skills and problem-solving abilities.

- Share examples of how you implemented safety measures or improved the efficiency of gas systems.

3. Showcase Your Safety Mindset

Emphasize your commitment to workplace safety and your adherence to industry regulations. Provide examples of safety protocols you have implemented or followed, and explain how you prioritize the well-being of yourself and others.

- Highlight your knowledge of lockout-tagout procedures, safe handling practices, and emergency response plans.

- Share an example of how you identified and mitigated a potential safety hazard in a gas system.

4. Prepare for Industry-Specific Questions

Anticipate questions about specific gas systems, equipment, and regulatory requirements. Study relevant industry standards and be prepared to discuss your experience with specialized tools or techniques.

- Review the National Fire Protection Association (NFPA) codes related to industrial gas systems.

- Research different types of gas detection and monitoring systems.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Industrial Gas Servicer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!