Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Instrument, Control and Electrical Technician (ICE Technician) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

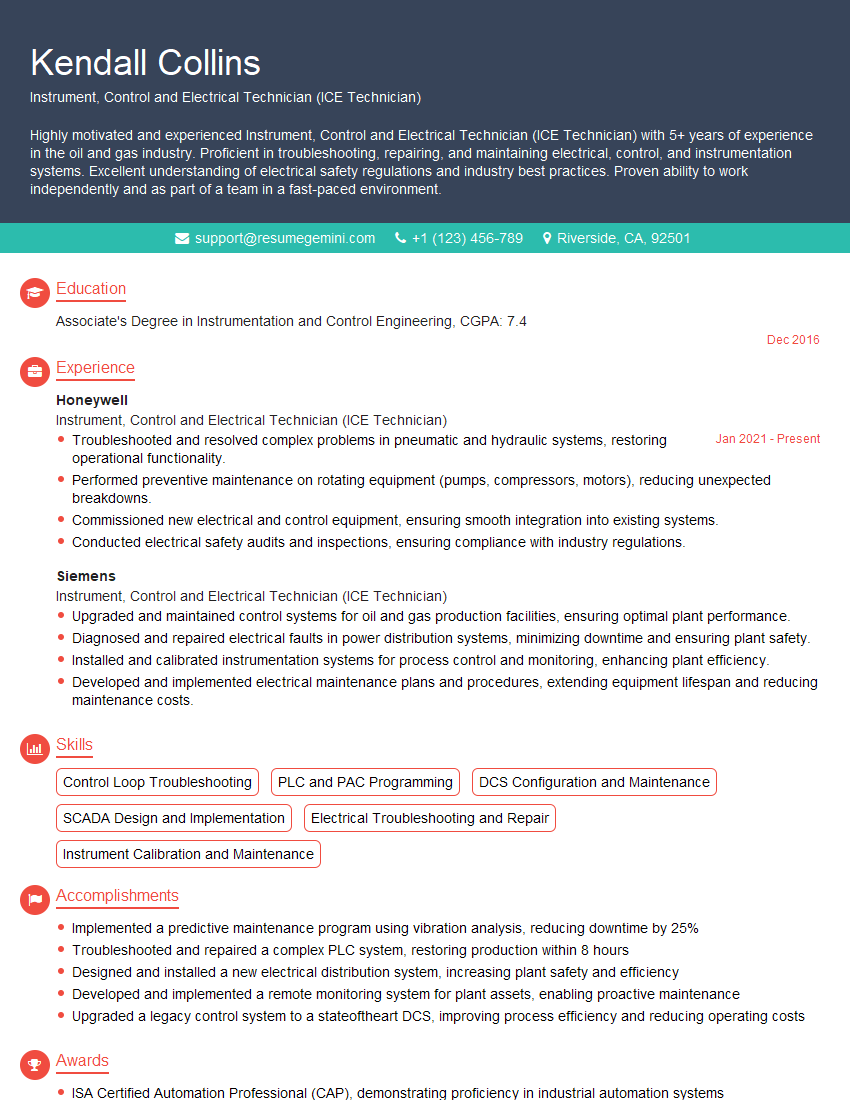

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument, Control and Electrical Technician (ICE Technician)

1. Explain the working principle of a PID controller?

A PID controller is a control loop feedback mechanism that uses three terms to calculate an error value: Proportional, Integral, and Derivative. The PID controller calculates the error as the difference between a desired setpoint and the measured process variable, and adjusts the control output to minimize the error.

- Proportional term (P): Responds to the current error and produces an output proportional to the magnitude of the error.

- Integral term (I): Responds to the accumulation of error over time and produces an output proportional to the integral of the error.

- Derivative term (D): Responds to the rate of change of the error and produces an output proportional to the derivative of the error.

2. Describe the different types of sensors used in industrial automation and their applications?

Temperature sensors

- Thermocouple: Measures temperature based on the Seebeck effect, where a voltage is generated between two dissimilar metals when heated.

- Resistance temperature detector (RTD): Measures temperature based on the change in electrical resistance of a conductor as temperature changes.

- Infrared sensor: Measures temperature by detecting infrared radiation emitted by an object.

Pressure sensors

- Bourdon tube: Measures pressure based on the deformation of a curved tube under pressure.

- Diaphragm pressure transducer: Measures pressure based on the deflection of a flexible diaphragm exposed to pressure.

- Strain gauge pressure transducer: Measures pressure based on the change in electrical resistance of a strain gauge attached to a diaphragm or bellows.

Flow sensors

- Turbine flowmeter: Measures flow rate based on the rotation of a turbine within the flow stream.

- Vortex flowmeter: Measures flow rate based on the shedding of vortices behind a bluff body placed in the flow stream.

- Ultrasonic flowmeter: Measures flow rate based on the measurement of the transit time of ultrasonic waves traveling upstream and downstream through the flow stream.

3. How do you calibrate a pressure transmitter?

To calibrate a pressure transmitter, follow these steps:

- Connect a pressure source (e.g., hand pump) to the pressure transmitter.

- Connect a pressure gauge or digital display to the pressure source.

- Set the pressure source to a known reference pressure.

- Adjust the calibration screw on the pressure transmitter until the output reading matches the reference pressure.

- Repeat steps 3-4 for multiple reference pressures across the transmitter’s operating range.

4. What is the difference between a PLC and a DCS?

- PLC (Programmable Logic Controller): A microprocessor-based device designed for industrial control applications. It typically uses ladder logic programming and is used for small to medium-sized control systems.

- DCS (Distributed Control System): A network of interconnected computers and controllers designed for large-scale process control applications. It typically uses a graphical user interface and is used for complex industrial processes.

5. Explain the difference between open-loop and closed-loop control systems?

- Open-loop control system: A control system in which the output is not measured and fed back to the controller. The output is determined solely by the input signal.

- Closed-loop control system: A control system in which the output is measured and fed back to the controller. The controller compares the measured output to the desired output and adjusts the input signal to minimize the error.

6. What is the purpose of a solenoid valve?

A solenoid valve is an electromechanically operated valve that uses an electromagnetic coil to control the flow of a fluid.

- Normally closed (NC) solenoid valve: The valve is closed when the coil is de-energized.

- Normally open (NO) solenoid valve: The valve is open when the coil is de-energized.

7. How do you troubleshoot a faulty motor?

To troubleshoot a faulty motor, follow these steps:

- Check the power supply to the motor.

- Inspect the motor for any physical damage or loose connections.

- Measure the resistance of the motor windings using a multimeter.

- Check the current draw of the motor while it is running.

- Listen for any unusual noises or vibrations coming from the motor.

8. What is the difference between a fuse and a circuit breaker?

- Fuse: A sacrificial device designed to open an electrical circuit when the current exceeds a predetermined level. It is a one-time use device that must be replaced after it blows.

- Circuit breaker: A reusable device designed to automatically open an electrical circuit when the current exceeds a predetermined level. It can be reset once the fault is cleared.

9. What are the different types of electrical enclosures?

- NEMA 1: Indoor enclosure suitable for clean and dry environments.

- NEMA 3: Indoor enclosure suitable for use in outdoor or damp environments.

- NEMA 4: Outdoor enclosure suitable for use in wet or corrosive environments.

- NEMA 7: Explosion-proof enclosure suitable for use in hazardous locations where flammable gases or vapors may be present.

10. What are the safety precautions to follow when working with electrical equipment?

- Always verify that the power is off before working on any electrical equipment.

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and non-conductive footwear.

- Use insulated tools and avoid contact with bare wires.

- Follow all lockout/tagout procedures.

- Do not work alone when working on energized equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument, Control and Electrical Technician (ICE Technician).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument, Control and Electrical Technician (ICE Technician)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Instrument, Control and Electrical Technicians (ICE Technicians) play a crucial role in maintaining and troubleshooting the instrumentation, control systems, and electrical equipment used in various industries. Their key job responsibilities include:

1. Instrumentation Maintenance

Involved in the installation, calibration, maintenance, and repair of instrumentation devices such as sensors, transmitters, analyzers, and controllers.

- Conduct regular inspections to ensure proper functioning and identify potential issues.

- Troubleshoot and diagnose faults using various diagnostic tools and techniques.

- Replace and repair faulty components to maintain optimal performance.

2. Control Systems Management

Manage and maintain control systems, including programmable logic controllers (PLCs), distributed control systems (DCSs), and other automation systems.

- Configure and program control systems to meet process requirements.

- Monitor and optimize control parameters to improve efficiency and productivity.

- Troubleshoot and resolve control system issues to minimize downtime.

3. Electrical System Maintenance

Maintain and repair electrical systems, including power distribution panels, lighting systems, and electrical motors.

- Install and wire electrical components according to specifications.

- Perform electrical testing and troubleshooting to ensure safety and reliability.

- Repair and replace faulty electrical components to maintain electrical integrity.

4. Troubleshooting and Repair

Troubleshoot and repair complex technical problems involving instrumentation, control systems, and electrical systems.

- Use diagnostic tools and techniques to identify the root cause of failures.

- Perform repairs and replacements to restore equipment to operational condition.

- Document troubleshooting and repair processes to facilitate future maintenance.

Interview Tips

To ace an interview for an ICE Technician position, candidates should prepare thoroughly by:

1. Researching the Company and Job Description

Familiarize yourself with the company’s industry, products or services, and the specific requirements of the ICE Technician role.

- Review the job description carefully and identify the key responsibilities and qualifications.

- Research the company’s website, LinkedIn page, and other sources to gather information about their culture, values, and recent projects.

2. Highlighting Relevant Skills and Experience

Showcase your technical skills, experience, and certifications that are relevant to the ICE Technician position.

- Quantify your accomplishments using specific metrics and examples.

- Emphasize your ability to troubleshoot and resolve complex technical issues.

- Discuss your experience with instrumentation, control systems, electrical systems, and software applications.

3. Demonstrating Problem-Solving Abilities

During the interview, be prepared to answer questions that assess your problem-solving skills.

- Describe a real-world scenario where you successfully identified and resolved a technical issue.

- Explain the process you used to troubleshoot the issue, including the tools and techniques you employed.

- Discuss the steps you took to implement and test a solution.

4. Asking Informed Questions

Prepare thoughtful questions to ask the interviewer at the end of the interview. This demonstrates your interest in the company and the position.

- Inquire about the company’s future plans and growth opportunities.

- Ask about the team you would be working with and the company’s mentorship or training programs.

- Seek clarification on any aspects of the job description or the company’s operations that you may have missed.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Instrument, Control and Electrical Technician (ICE Technician) role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.