Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Furnace Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

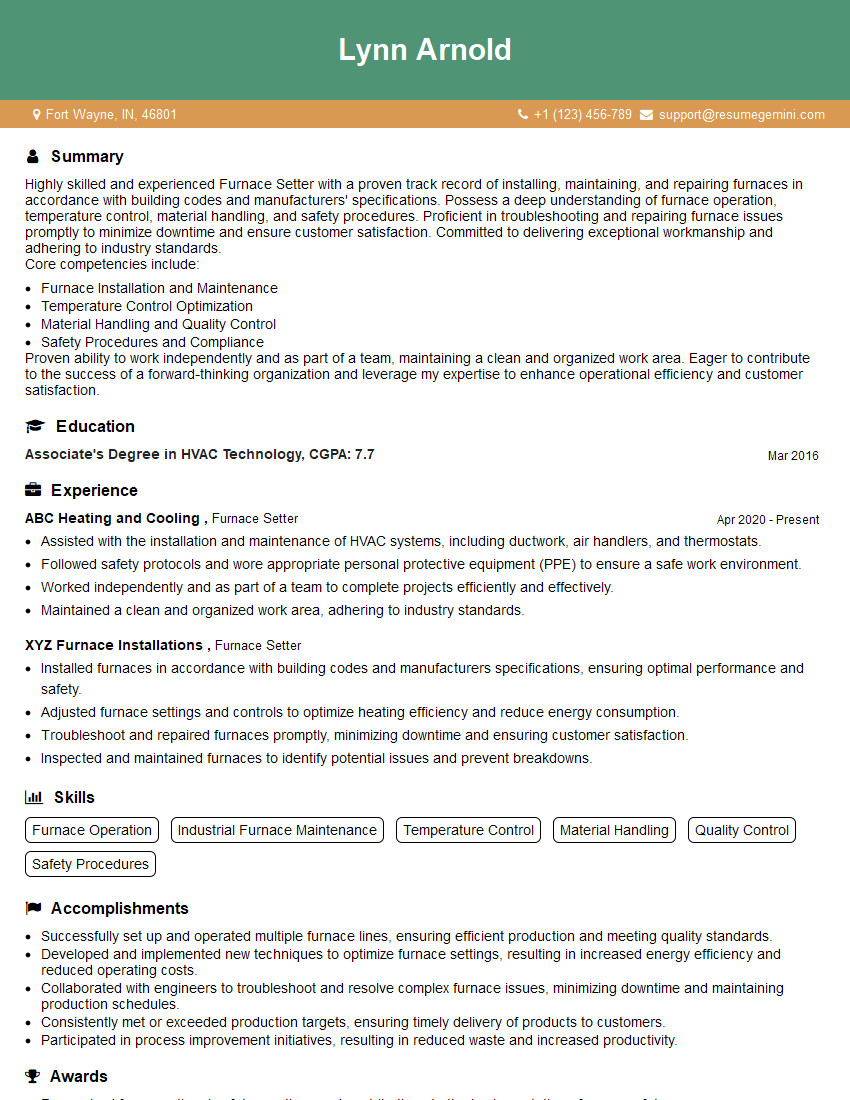

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Furnace Setter

1. What are the key responsibilities of a Furnace Setter?

As a Furnace Setter, I would be responsible for:

- Setting up and operating furnaces to melt and cast metal

- Monitoring and controlling the temperature and flow of molten metal

- Inspecting and preparing molds and dies for casting

- Adjusting and maintaining furnace equipment to ensure optimal performance

- Following established safety procedures and adhering to quality standards

2. Describe the different types of furnaces used in the metalworking industry.

Electric Arc Furnaces

- Use electric arcs to melt scrap metal

- Produce high-quality steel and other alloys

Induction Furnaces

- Heat metal by inducing electric currents

- Can precisely control the temperature and composition of the molten metal

Gas-Fired Furnaces

- Use natural gas or propane to heat metal

- Commonly used for melting and casting aluminum and brass

3. What are the safety precautions that must be taken when operating a furnace?

- Wear appropriate personal protective equipment (PPE), including heat-resistant clothing, gloves, and eye protection

- Ensure proper ventilation to prevent exposure to hazardous fumes and gases

- Never touch molten metal or equipment without proper insulation

- Follow established operating procedures and lockout/tagout protocols

- Be aware of potential hazards such as electrical hazards, fire risks, and molten metal spills

4. How do you monitor and control the temperature and flow of molten metal?

- Use thermocouples and other temperature-measuring devices to monitor the temperature of the molten metal

- Adjust furnace settings such as power, gas flow, and air flow to control the temperature

- Use flowmeters and other devices to monitor and regulate the flow of molten metal

- Observe the appearance and behavior of the molten metal to detect any irregularities

5. Describe the different types of molds and dies used in metal casting.

Sand Molds

- Made from compacted sand and binders

- Inexpensive and can be used for complex shapes

Metal Molds

- Made from metal, such as steel or cast iron

- More durable and can produce higher-quality castings

Permanent Molds

- Made from a combination of materials

- Designed for high-volume production

6. What are the different types of defects that can occur in metal castings?

Shrinkage Cavities

- Caused by the solidification of molten metal

- Can weaken the casting

Porosity

- Caused by trapped air or gas bubbles

- Can reduce the strength and durability of the casting

Hot Tears

- Caused by thermal stresses during cooling

- Can lead to catastrophic failure

7. How do you troubleshoot common problems with furnace operation?

- Identify the symptoms of the problem

- Check furnace settings and equipment

- Inspect the molten metal and molds/dies

- Consult with supervisors or technical experts

- Implement corrective actions and monitor the results

8. Describe the different methods used to heat metal in a furnace.

Direct Heating

- Heat is applied directly to the metal

- Examples: Electric arc furnaces, gas-fired furnaces

Indirect Heating

- Heat is transferred to the metal through a barrier

- Examples: Induction furnaces, salt bath furnaces

Radiant Heating

- Heat is transferred to the metal through electromagnetic radiation

- Examples: Electric resistance furnaces, infrared furnaces

9. Explain the importance of maintaining accurate temperature control in furnace operation.

- Ensures the desired properties of the molten metal

- Prevents defects such as shrinkage cavities and hot tears

- Optimizes energy consumption

- Improves productivity and yield

- Ensures safety and avoids equipment damage

10. Describe the use of computer-controlled systems in furnace operation.

- Automated temperature control and adjustment

- Monitoring and recording of furnace data

- Diagnostics and troubleshooting

- Improved efficiency and consistency

- Reduced operator error

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Furnace Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Furnace Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Furnace Setter is responsible for setting up, operating, and maintaining furnaces used in industrial processes. Responsibilities also include monitoring and controlling furnace temperature and atmosphere, as well as loading and unloading materials.

1. Furnace Setup and Operation

Setting up and operating furnaces according to specifications, including temperature, atmosphere, and other parameters.

2. Monitoring and Control

Monitoring and controlling furnace temperature, atmosphere, and other parameters to ensure optimal operation.

3. Material Handling

Loading and unloading materials from the furnace using appropriate equipment.

4. Equipment Maintenance

Performing preventive maintenance on furnaces and related equipment to ensure smooth operation.

5. Quality Assurance

Ensuring that materials meet specified quality standards by monitoring and adjusting furnace parameters as needed.

6. Safety

Following safety procedures and protocols to ensure a safe work environment.

Interview Tips

To prepare for an interview for a Furnace Setter position, it is important to familiarize yourself with the key job responsibilities and common interview questions. Here are some tips to help you ace the interview:

1. Research the Company

Research the company’s website, industry news, and social media to gain insight into their values, culture, and current projects.

2. Practice Common Interview Questions

Practice answering common interview questions such as “Tell me about yourself,” “Why are you interested in this role?,” “What are your strengths and weaknesses?,” and “Why should we hire you?”

3. Highlight Relevant Experience and Skills

Emphasize your experience in furnace operation, monitoring, and maintenance. Highlight your skills in quality assurance, safety, and problem-solving.

4. Be Prepared to Discuss Technical Details

Review furnace types, temperature control systems, and safety procedures. Be prepared to discuss your understanding of these technical aspects.

5. Dress Professionally and Arrive Punctually

Dress professionally and arrive for the interview on time. This demonstrates your respect for the interviewer and the company.

6. Ask Questions

Asking thoughtful questions at the end of the interview shows your interest in the role and the company. Ask about the company’s growth plans, safety culture, and opportunities for advancement.

7. Follow Up

After the interview, send a thank-you email to the interviewer. Restate your interest in the position and briefly highlight your qualifications.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Furnace Setter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Furnace Setter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.