Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Quality Control Tech, Raw Materials position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

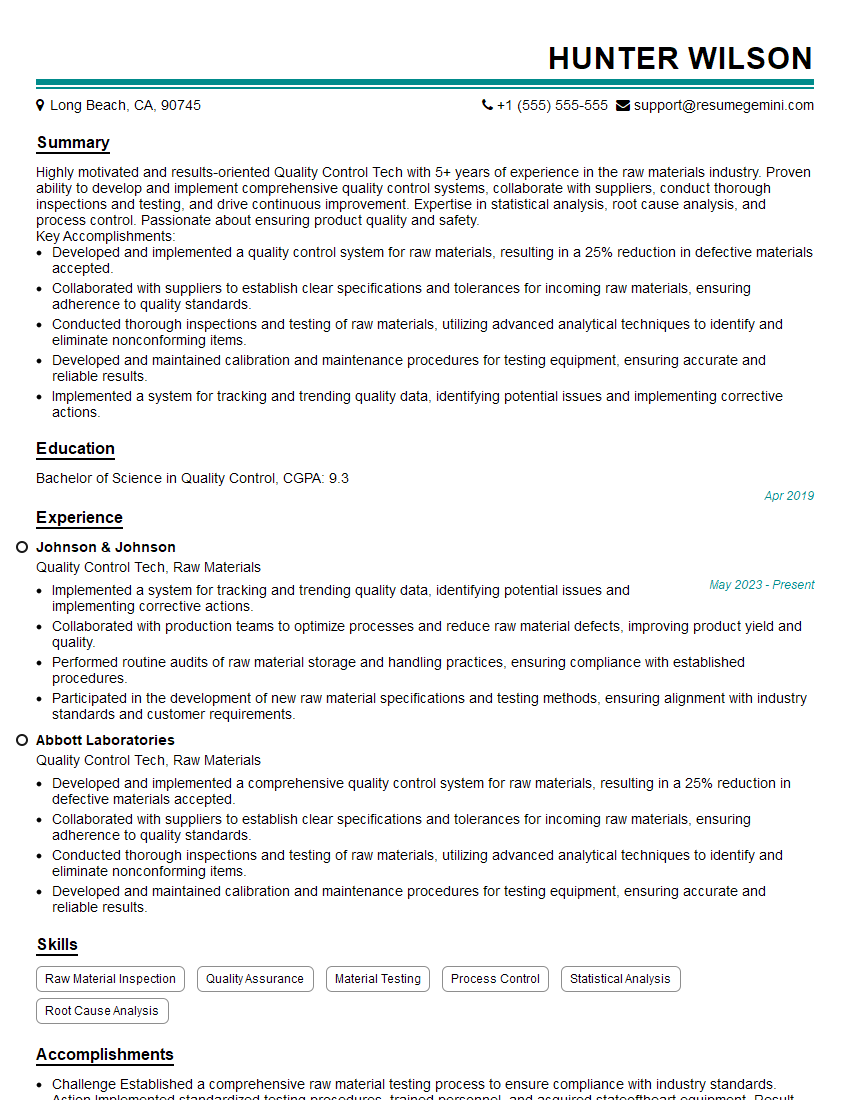

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Quality Control Tech, Raw Materials

1. Describe the process of sampling and testing raw materials for quality control.

The process of sampling and testing raw materials for quality control involves several key steps:

- Sampling: Representative samples are collected from the raw material based on established sampling plans.

- Sample preparation: Samples may undergo preparation steps such as grinding, drying, or chemical extraction to prepare them for testing.

- Testing: Samples are analyzed using various analytical techniques, such as chemical testing, physical testing, and microbiological testing, to determine their properties and characteristics.

- Data analysis: Test results are analyzed to assess compliance with specifications and identify any deviations.

- Documentation and reporting: Test results and any deviations are documented and reported to relevant parties, such as suppliers, production, and management.

2. What is the importance of calibration and verification in analytical testing?

Calibration

- Ensures accuracy of analytical instruments by comparing their readings to known standards.

- Establishes traceability to reference materials or standards.

- Detects and corrects instrument drift or errors.

Verification

- Confirms the accuracy and precision of test methods and procedures.

- Provides evidence that the test system is operating within acceptable limits.

- Ensures reliability and validity of test results.

3. Explain how you would interpret a certificate of analysis (CoA) for a raw material.

- Review the material identification: Verify that the CoA matches the raw material being tested.

- Examine test results: Compare the test results to the established specifications for the raw material.

- Assess compliance: Determine if the raw material meets the required specifications based on the test results.

- Consider uncertainties: Account for any uncertainties or tolerances associated with the test methods.

- Make a decision: Release the raw material for use or reject it based on the interpretation of the CoA.

4. How do you handle out-of-specification (OOS) results?

- Confirm the results: Repeat the tests or consult with other analysts to verify the OOS results.

- Investigate the cause: Analyze the process, equipment, or other factors that may have contributed to the OOS.

- Implement corrective actions: Address the root cause of the OOS results to prevent recurrence.

- Document the investigation: Record the findings and actions taken in a clear and concise report.

- Communicate with stakeholders: Inform relevant parties, such as suppliers, production, and quality management, about the OOS results and corrective actions.

5. Describe the role of statistical process control (SPC) in quality control.

- Monitoring process stability: SPC techniques help track and analyze process data to identify and control variation.

- Identifying trends and patterns: SPC charts display data over time, allowing for the identification of trends, patterns, and shifts.

- Process improvement: By analyzing SPC data, areas for improvement can be identified and targeted for optimization.

- Early detection of problems: SPC techniques can detect small changes in a process, enabling early intervention to prevent major issues.

- Customer confidence: SPC provides evidence of process control and product quality, building customer confidence.

6. What are the different types of audits that may be performed in a quality control laboratory?

- Internal audits: Conducted by internal personnel to assess compliance with established procedures and regulations.

- External audits: Performed by external organizations, such as regulatory agencies or certification bodies, to verify adherence to standards.

- Process audits: Focus on evaluating the effectiveness and efficiency of specific processes within the laboratory.

- System audits: Assess the overall quality management system and its effectiveness in meeting quality objectives.

- Supplier audits: Conducted to evaluate the quality systems of raw material suppliers.

7. How do you stay updated on the latest quality control techniques and regulations?

- Attend conferences and workshops: Participate in industry events to learn about new methods and best practices.

- Read industry publications: Keep up with journals and magazines to stay informed about advancements in quality control.

- Take online courses: Enroll in online programs or certifications to enhance knowledge and skills.

- Network with peers: Engage with colleagues and experts in the field to exchange knowledge and stay abreast of emerging trends.

- Monitor regulatory updates: Subscribe to newsletters or attend webinars to stay informed about changes in regulations and standards.

8. What are the challenges in ensuring the quality of raw materials for food products?

- Variability in raw materials: Natural products can vary in composition and quality due to factors such as cultivation conditions and harvesting time.

- Contamination risks: Raw materials may be susceptible to contamination with microorganisms, pesticides, or other substances.

- Traceability and documentation: Ensuring proper traceability and documentation of raw materials is crucial for food safety and quality assurance.

- Supplier management: Establishing and maintaining relationships with reliable suppliers is essential for consistent quality of raw materials.

- Regulatory compliance: Meeting food safety and quality regulations requires adherence to strict standards and documentation.

9. How do you prioritize tasks and manage your workload as a Quality Control Tech?

- Identify critical tasks: Determine which tasks have the highest priority based on urgency and impact.

- Create a schedule: Establish a realistic schedule that allows for efficient completion of tasks.

- Delegate responsibilities: If possible, delegate non-critical tasks to others to free up time for more important tasks.

- Utilize technology: Leverage technology tools such as task management software to track progress and stay organized.

- Communicate proactively: Keep stakeholders informed about progress and any potential delays.

10. Describe your experience with using quality control software or systems.

I am familiar with various quality control software and systems, including:

- Laboratory information management systems (LIMS): Experience with configuring and using LIMS to manage sample data, test results, and quality control records.

- Statistical process control (SPC) software: Proficient in using SPC tools to analyze process data, identify trends, and improve quality.

- Electronic quality records (EQR) systems: Experience in implementing and maintaining EQR systems to manage and track quality documentation electronically.

- Quality assurance software: Familiar with using software for non-conformance management, corrective and preventive actions (CAPA), and risk assessments.

- Data analysis software: Proficient in using software for data analysis, statistical calculations, and reporting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Quality Control Tech, Raw Materials.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Quality Control Tech, Raw Materials‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Quality Control Tech, Raw Materials, plays a critical role in ensuring the quality and safety of raw materials used in the production process.

1. Raw Material Inspection and Testing

Inspect and test incoming raw materials to verify their compliance with specifications.

- Conduct visual inspections for defects and contamination.

- Perform laboratory tests to analyze chemical and physical properties.

2. Quality Control Documentation

Document all inspection and testing results accurately and maintain detailed records.

- Maintain quality control logs and reports.

- Identify and investigate any deviations from specifications.

3. Supplier Management

Monitor supplier performance and collaborate with vendors to ensure continuous improvement.

- Conduct audits of supplier facilities.

- Provide feedback and technical guidance to suppliers.

4. Process Improvement

Identify opportunities for process improvement and implement solutions to enhance quality.

- Analyze quality data and trends.

- Participate in continuous improvement initiatives.

Interview Tips

To ace the interview, focus on showcasing your skills, experience, and enthusiasm for quality control.

1. Research the Company and the Role

Thoroughly research the company and the specific responsibilities of the Quality Control Tech role, including the industry and the size and scope of the company.

- Visit the company website, read industry news, and consult professional organizations.

- Tailor your answers and emphasize how your skills align with the company’s needs.

2. Practice Your Answers

Prepare and practice answers to common interview questions related to your skills, experience, and why you are interested in the role.

- Anticipate questions about your laboratory testing experience, attention to detail, and problem-solving abilities.

- Use the STAR method to structure your answers: Situation, Task, Action, Result.

3. Showcase Your Passion for Quality

Emphasize your passion for ensuring product quality and safety, and demonstrate your understanding of how quality control contributes to the overall success of the company.

- Describe your experiences in implementing quality improvement initiatives.

- Explain how your attention to detail has prevented or resolved quality issues.

4. Ask Relevant Questions

Prepare thoughtful questions to ask the interviewer about the company’s quality standards, the role’s responsibilities, and the opportunities for career growth.

- This demonstrates your interest and engagement in the role and the company.

- Ask about the company’s quality certifications and their commitment to continuous improvement.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Quality Control Tech, Raw Materials role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.