Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Oil Burner Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

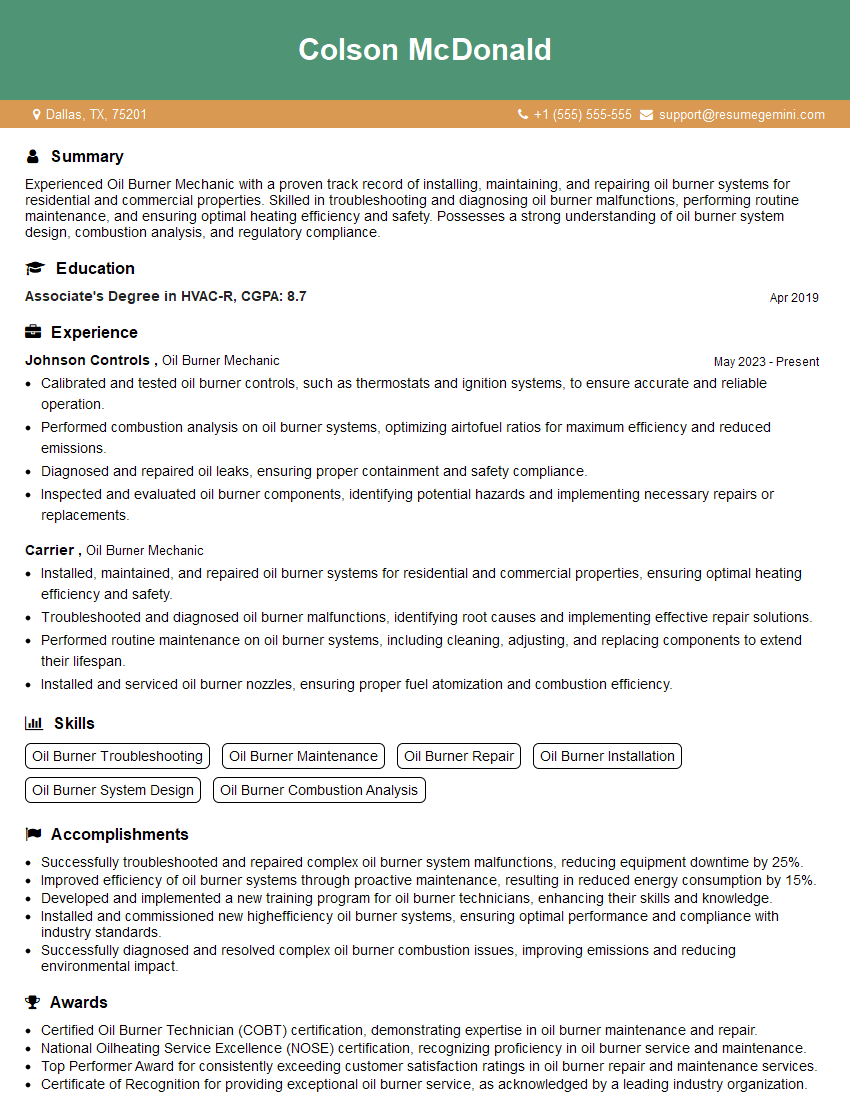

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Burner Mechanic

1. Explain the steps involved in troubleshooting a malfunctioning oil burner?

The steps involved in troubleshooting a malfunctioning oil burner are as follows:

- Inspect the flame: Check the flame pattern to identify any irregularities or signs of incomplete combustion.

- Verify the fuel supply: Ensure that there is sufficient fuel in the tank and that fuel is flowing properly to the burner.

- Inspect the air supply: Ensure that there is adequate airflow to the burner, both for combustion and cooling.

- Check the electrical system: Verify the electrical connections and components, including the transformer, ignition module, and safety switches.

- Test the burner controls: Check the operation of the thermostat, limit controls, and other safety features.

- Inspect the combustion chamber: Examine the combustion chamber for any signs of corrosion, damage, or blockages.

- Analyze the exhaust gases: Use a combustion analyzer to measure the composition of the exhaust gases and identify any imbalances.

2. How do you adjust the air-fuel ratio in an oil burner?

Fuel Pressure Method:

- Measure the fuel pressure at the nozzle.

- Adjust the air damper to achieve the desired fuel pressure as per the manufacturer’s specifications.

- Re-measure the fuel pressure to ensure it is within the recommended range.

Flue Gas Analysis Method:

- Use a combustion analyzer to measure the flue gas composition.

- Adjust the air damper to achieve the optimal oxygen and carbon monoxide levels as per the manufacturer’s specifications.

- Re-measure the flue gas composition to ensure it is within the recommended range.

3. Describe the different types of oil burner nozzles and their applications.

Pressure atomizing nozzles:

- Use high pressure to break up the oil into small droplets.

- Produce a hollow cone-shaped spray.

- Used in commercial and industrial burners.

Rotary atomizing nozzles:

- Use a spinning disk to create a fine mist of oil droplets.

- Produce a solid cone-shaped spray.

- Used in residential and light commercial burners.

Air atomizing nozzles:

- Combine oil and air to create a fine mist of oil droplets.

- Produce a solid cone-shaped spray.

- Used in large industrial burners and power plants.

4. How do you diagnose and repair a leaking oil pump?

Diagnosis:

- Check for signs of oil leakage around the pump housing.

- Inspect the pump seals for wear or damage.

- Listen for unusual noises, such as grinding or squealing, which may indicate pump problems.

Repair:

- Replace worn or damaged pump seals.

- Tighten loose fittings or connections.

- In some cases, the entire pump may need to be replaced.

5. Explain the safety precautions that must be taken when working with oil burners.

- Always wear appropriate personal protective equipment: Gloves, safety glasses, and fire-resistant clothing.

- Ensure proper ventilation: Oil burners produce carbon monoxide and other harmful gases.

- Never leave an oil burner unattended: Regularly monitor the burner for any signs of malfunction.

- Follow manufacturer’s instructions: Refer to the manufacturer’s manual for specific safety precautions and operating procedures.

- Be aware of the location of fire extinguishers and know how to use them: In the event of a fire, be prepared to quickly extinguish it.

6. Describe the different types of oil burner controls and their functions.

Thermostats:

- Sense the room temperature and turn the burner on or off to maintain a desired temperature.

Limit controls:

- Protect the burner and system from overheating by shutting it off if the temperature exceeds a safe limit.

Safety switches:

- Monitor various operating parameters, such as flame presence, airflow, and system pressure, and shut off the burner if any unsafe conditions are detected.

Ignition systems:

- Generate a spark to ignite the oil in the burner.

7. Explain the importance of regular maintenance for oil burners.

- Improved efficiency: Regular maintenance helps keep the burner operating at optimal efficiency, reducing fuel consumption and lowering operating costs.

- Extended lifespan: Proper maintenance can extend the lifespan of the burner and its components.

- Safety: Regular maintenance helps prevent potential safety hazards, such as leaks, fires, and carbon monoxide poisoning.

- Compliance with regulations: In many jurisdictions, regular maintenance is required by law to ensure the safe and efficient operation of oil burners.

8. What are the common problems faced by oil burners and their troubleshooting techniques?

Problem: Burner won’t start

- Troubleshooting: Check fuel supply, electrical connections, safety switches, and ignition system.

Problem: Burner flames out

- Troubleshooting: Check airflow, fuel supply, nozzle condition, and combustion chamber cleanliness.

Problem: Soot buildup on the combustion chamber

- Troubleshooting: Check air-fuel ratio, nozzle condition, and proper combustion settings.

9. How do you ensure that an oil burner is operating at peak efficiency?

- Regular maintenance: Perform regular cleaning, inspections, and adjustments as per manufacturer’s recommendations.

- Proper adjustment: Ensure proper air-fuel ratio, nozzle condition, and burner alignment.

- Monitor combustion: Use combustion analyzers to monitor and optimize the combustion process for maximum efficiency.

- Upgrade to high-efficiency components: Consider upgrading to energy-efficient nozzles, pumps, and other components.

10. What is your experience with using combustion analyzers for oil burner troubleshooting and fine-tuning?

In my previous role as an Oil Burner Mechanic, I extensively utilized combustion analyzers for troubleshooting and fine-tuning oil burners. I am proficient in:

- Interpreting combustion gas readings (CO, O2, CO2, NOx) to diagnose combustion imbalances.

- Adjusting air-fuel ratios and burner settings to optimize combustion efficiency and reduce emissions.

- Using advanced combustion analysis techniques, such as flue gas stack temperature profiling, to identify and correct specific combustion problems.

- Preparing detailed combustion reports for clients, including recommendations for improvement and maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Burner Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Burner Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Oil Burner Mechanic is responsible for installing, maintaining, and repairing oil burners within residential and commercial buildings. The effective functioning of an oil burner is crucial to ensure the safety and comfort of a building’s occupants. The primary responsibilities of an Oil Burner Mechanic include:

1. Installation and Maintenance

Oil Burner Mechanics are responsible for installing and maintaining oil burners. This involves understanding and working with various oil burner components such as combustion chambers, fuel pumps, and ignition systems. They ensure that the burners are installed according to code, meet safety standards, and operate efficiently.

2. Troubleshooting and Repair

When an oil burner malfunctions, it is the responsibility of the mechanic to diagnose the issue and perform necessary repairs. They use their knowledge of burner components and systems to identify problems such as ignition issues, fuel flow malfunctions, or combustion system failures. Oil Burner Mechanics have the tools and expertise to resolve these issues promptly and restore the burner to proper operation.

3. Routine Inspections and Cleaning

To ensure optimal performance and prevent future issues, Oil Burner Mechanics conduct routine inspections and cleaning of burners. They inspect components for signs of wear, corrosion, or damage. Regular cleaning helps maintain the burner’s efficiency, reduces the risk of breakdowns, and prolongs its lifespan.

4. Safety Compliance

Oil Burner Mechanics must adhere to strict safety protocols and regulations. They follow established codes and standards to ensure the safe operation of oil burners. This involves checking for leaks, proper ventilation, and compliance with safety regulations to minimize the risk of fire or other hazards.

Interview Tips

Preparing for an interview as an Oil Burner Mechanic is essential to showcase your skills and qualifications. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take time to research the company and the specific oil burner mechanic position you are applying for. Understanding the company’s mission, values, and industry standing will enable you to tailor your responses to the interviewer’s questions.

2. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare your answers accordingly. Consider your experiences, skills, and how they align with the job requirements. Practice delivering your answers concisely and confidently.

3. Highlight Your Relevant Experience and Skills

Emphasize your hands-on experience with oil burner installation, maintenance, and repair. Showcase your knowledge of burner components and systems and highlight your ability to diagnose and resolve issues efficiently.

4. Demonstrate Your Safety Consciousness

Safety is paramount in oil burner maintenance. Assure the interviewer of your safety-first mindset and highlight your understanding of safety protocols and regulations. Provide examples of how you prioritize safety measures to prevent accidents.

5. Be Enthusiastic and Professional

Convey your enthusiasm for the role and express your passion for working with oil burners. Maintain a professional demeanor throughout the interview, dress appropriately, and arrive on time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Oil Burner Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Oil Burner Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.