Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Oil Burner Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

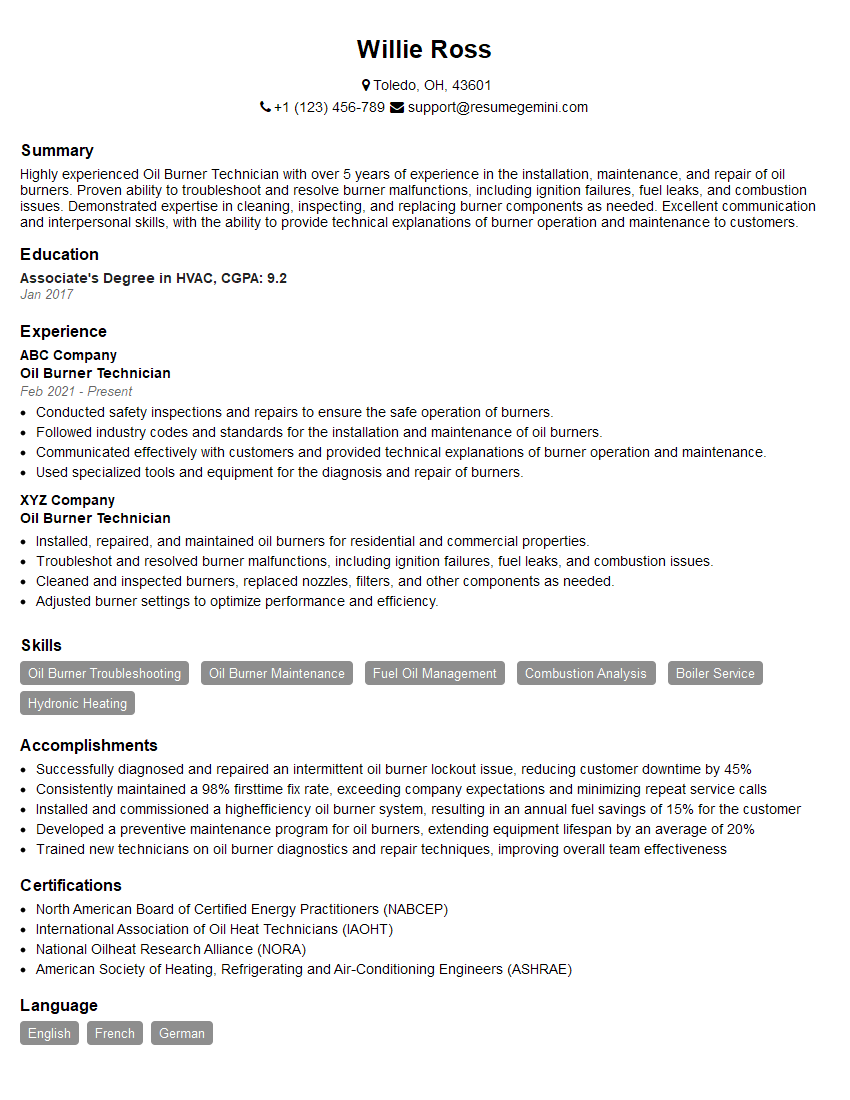

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Burner Technician

1. Explain the working principle of an Oil Burner?

An Oil Burner operates on the principle of combustion, where oil is mixed with air and ignited to produce heat. The burner consists of several key components that facilitate this process:

- Oil Pump: The oil pump draws oil from the storage tank and supplies it to the burner.

- Nozzle: The nozzle atomizes the oil into tiny droplets, creating a fine mist that can be easily mixed with air.

- Air Blower: The air blower provides a stream of air to mix with the oil droplets, ensuring efficient combustion.

- Igniter: The igniter initiates the combustion process by creating a spark that ignites the oil-air mixture.

- Combustion Chamber: The combustion chamber provides a space for the oil and air to burn, releasing heat.

2. Describe the different types of Oil Burners?

Residential Oil Burners:

- Pressure Atomizing Burners: Use a pump to create high pressure, forcing oil through a nozzle to atomize it.

- Rotary Cup Burners: Use a rotating cup to create air turbulence and atomize the oil.

Commercial and Industrial Oil Burners:

- Air Atomizing Burners: Use high-pressure air to atomize the oil.

- Steam Atomizing Burners: Use high-pressure steam to atomize the oil.

- Mechanical Atomizing Burners: Use a centrifugal or rotary device to atomize the oil.

3. What are the common problems associated with Oil Burners and how do you troubleshoot them?

Common problems with Oil Burners and their troubleshooting methods include:

- No Ignition: Check for power supply, faulty igniter, or clogged nozzle.

- Sooting: Indicates incomplete combustion, check for dirty nozzle, insufficient air supply, or incorrect oil-to-air ratio.

- Flame Instability: May be caused by nozzle issues, air flow problems, or faulty combustion chamber.

- Burner Lockout: Occurs due to multiple failed ignition attempts, check for ignition issues or fuel supply.

4. How do you perform routine maintenance on an Oil Burner?

Routine maintenance involves the following steps:

- Inspection: Inspect the burner for any visible damage or wear.

- Cleaning: Clean the nozzle, combustion chamber, and air blower to remove soot and debris.

- Adjustments: Adjust the oil-to-air ratio and ignition timing as per manufacturer’s specifications.

- Lubrication: Lubricate moving parts to ensure smooth operation.

- Testing: Test the burner to ensure it operates correctly and efficiently.

5. What safety precautions should be taken when working with Oil Burners?

Safety precautions include:

- Proper Training: Ensure proper training and certification before handling oil burners.

- Ventilation: Work in well-ventilated areas to prevent carbon monoxide exposure.

- Fuel Handling: Handle fuel carefully to avoid spills or leaks.

- Electrical Safety: Inspect electrical connections and ensure proper grounding to prevent electrical hazards.

- Emergency Preparedness: Have fire extinguishers and emergency shutdown procedures in place.

6. Explain the importance of combustion efficiency in Oil Burners?

Combustion efficiency is crucial because it directly affects the overall performance and cost-effectiveness of the burner. High combustion efficiency means that a greater proportion of the fuel is converted into heat, resulting in lower fuel consumption and reduced emissions. Factors affecting combustion efficiency include:

- Oil-to-air ratio

- Nozzle condition

- Combustion chamber design

- Proper maintenance and adjustments

7. What are the different types of nozzles used in Oil Burners and how do they affect performance?

The type of nozzle used in an oil burner can have a significant impact on performance.

Types of Nozzles:

- Hollow Cone Nozzles: Produce a hollow cone-shaped spray pattern, providing a wide distribution of oil droplets.

- Solid Cone Nozzles: Produce a solid cone-shaped spray pattern, providing a more concentrated distribution of oil droplets.

Factors Affecting Nozzle Performance:

- Spray Angle: The angle at which the oil is sprayed affects the coverage and intensity of the flame.

- Flow Rate: The flow rate of the nozzle determines the amount of oil delivered to the combustion chamber.

- Condition: Wear or damage to the nozzle can affect the spray pattern and combustion efficiency.

8. How do you determine the correct nozzle size for an Oil Burner?

The correct nozzle size for an oil burner is determined based on the burner’s heat output and fuel type. Several factors need to be considered:

- Burner Capacity: The heat output of the burner in British Thermal Units per hour (BTU/hr).

- Fuel Type: Different fuels, such as kerosene or distillate oil, have different properties that affect nozzle selection.

- Combustion Efficiency: The desired level of combustion efficiency, which can be influenced by nozzle size.

- Manufacturer’s Recommendations: The burner manufacturer typically provides guidelines for nozzle selection based on burner model and fuel type.

9. Describe the role of an Air Blower in an Oil Burner?

The air blower in an oil burner plays a crucial role in the combustion process:

- Oxygen Supply: The air blower provides a stream of air to the combustion chamber, which is necessary for complete combustion of the oil.

- Oil Atomization: The air stream helps atomize the oil droplets, creating a fine mist that can easily mix with air for efficient combustion.

- Flame Stability: The air blower helps stabilize the flame by providing the required airflow pattern within the combustion chamber.

- Combustion Efficiency: Proper air supply ensures complete combustion, reducing soot and emissions, and improving combustion efficiency.

10. Explain the process of troubleshooting an Oil Burner that is not igniting?

Troubleshooting an oil burner that is not igniting involves a systematic approach:

- Verify Power Supply: Ensure that the burner is receiving power and that the electrical connections are secure.

- Check Igniter:Inspect the igniter for proper operation, replace if faulty.

- Examine Nozzle: Inspect the nozzle for clogging or damage, clean or replace as needed.

- Verify Fuel Supply: Ensure that there is an adequate fuel supply and that the fuel lines are not blocked.

- Inspect Air Blower:Make sure the air blower is functioning correctly, providing sufficient airflow for combustion.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Burner Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Burner Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oil Burner Technicians are responsible for the installation, maintenance, and repair of oil burners and related equipment.

1. Installation and Setup

Install new oil burners and related equipment, ensuring that they are properly connected and functioning safely.

- Read and interpret blueprints and schematics.

- Assemble and install oil burners, pumps, tanks, and piping.

2. Maintenance and Inspection

Conduct regular maintenance inspections to ensure that oil burners and equipment are operating efficiently and safely.

- Clean and inspect burners, pumps, and other components.

- Replace worn or damaged parts.

3. Troubleshooting and Repair

Diagnose and repair any problems that arise with oil burners and equipment.

- Identify and resolve issues with ignition, combustion, and fuel flow.

- Perform repairs on equipment, including replacing parts and adjusting settings.

4. Safety and Compliance

Ensure that oil burners and equipment are operating in a safe and compliant manner.

- Follow all safety regulations and industry standards.

- Test and certify equipment for compliance.

Interview Tips

Preparing for an oil burner technician interview can increase your chances of success. Here are some tips to help you prepare effectively.

1. Research the Role and Company

Take the time to understand the specific responsibilities of the oil burner technician role and the company you are applying to.

- Review the job description and company website.

- Look up industry-relevant news and trends.

2. Highlight Relevant Skills and Experience

Emphasize the skills and experience that are most relevant to the job requirements.

- Quantify your accomplishments using specific metrics.

- Prepare examples that demonstrate your technical abilities and problem-solving skills.

3. Practice Common Interview Questions

Prepare answers to common interview questions, such as:

- Tell me about your experience in oil burner installation.

- How do you diagnose and repair problems with oil burners?

- What are your strengths and weaknesses as an oil burner technician?

4. Dress Professionally and Be Punctual

Dress professionally and arrive on time for your interview. This demonstrates respect for the interviewer and the company.

- Consider wearing business casual attire.

- Plan your route and allow ample time for travel.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Oil Burner Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Oil Burner Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.