Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Refrigeration Mechanic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Refrigeration Mechanic so you can tailor your answers to impress potential employers.

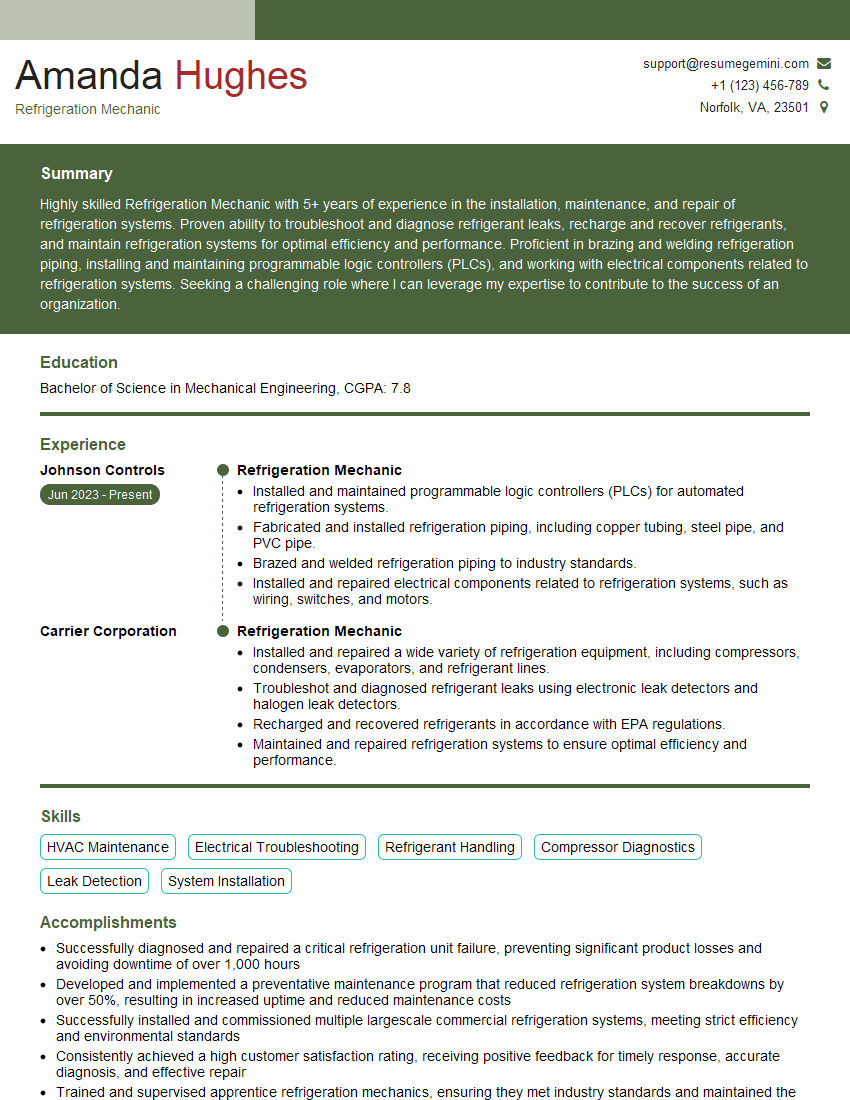

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Refrigeration Mechanic

1. Explain the refrigeration cycle?

The refrigeration cycle is a thermodynamic process that moves heat from one area to another. It is used in refrigeration and air conditioning systems to cool a space. The cycle consists of four main steps:

- Compression: The refrigerant is compressed by a compressor, which increases its pressure and temperature.

- Condensation: The compressed refrigerant is then passed through a condenser, where it releases heat to the surrounding environment and condenses into a liquid.

- Expansion: The liquid refrigerant is then passed through an expansion valve, which reduces its pressure and temperature.

- Evaporation: The low-pressure refrigerant is then passed through an evaporator, where it absorbs heat from the surrounding environment and evaporates into a gas.

2. What are the different types of refrigerants?

CFCs (Chlorofluorocarbons)

- These were the first refrigerants used, but they have been phased out due to their ozone-depleting potential.

- Examples: R-12, R-11

HCFCs (Hydrochlorofluorocarbons)

- These were developed as a replacement for CFCs, and they have a lower ozone-depleting potential.

- Examples: R-22, R-134a

HFCs (Hydrofluorocarbons)

- These are the most common refrigerants used today, and they have no ozone-depleting potential.

- Examples: R-410A, R-134a

Natural refrigerants

- These are refrigerants that occur naturally, such as ammonia, carbon dioxide, and water.

- They have no ozone-depleting potential and a low global warming potential.

3. What are the different types of refrigeration systems?

There are two main types of refrigeration systems:

- Vapor-compression systems: These are the most common type of refrigeration system. They use a compressor to compress the refrigerant, which increases its pressure and temperature. The compressed refrigerant is then passed through a condenser, where it releases heat to the surrounding environment and condenses into a liquid. The liquid refrigerant is then passed through an expansion valve, which reduces its pressure and temperature. The low-pressure refrigerant is then passed through an evaporator, where it absorbs heat from the surrounding environment and evaporates into a gas. The gas is then compressed again by the compressor, and the cycle repeats.

- Absorption systems: These systems use a heat source, such as a flame or an electric heating element, to boil a refrigerant. The boiling refrigerant vapor is then passed through a condenser, where it releases heat to the surrounding environment and condenses into a liquid. The liquid refrigerant is then passed through an expansion valve, which reduces its pressure and temperature. The low-pressure refrigerant is then passed through an evaporator, where it absorbs heat from the surrounding environment and evaporates into a gas. The gas is then absorbed by a solution of water and lithium bromide. The solution is then pumped back to the boiler, where the refrigerant is boiled off again.

4. What are the different components of a refrigeration system?

The main components of a refrigeration system are:

- Compressor: The compressor is the heart of the refrigeration system. It compresses the refrigerant, which increases its pressure and temperature.

- Condenser: The condenser is where the compressed refrigerant releases heat to the surrounding environment and condenses into a liquid.

- Expansion valve: The expansion valve is where the pressure and temperature of the liquid refrigerant is reduced.

- Evaporator: The evaporator is where the low-pressure refrigerant absorbs heat from the surrounding environment and evaporates into a gas.

- Refrigerant: The refrigerant is the fluid that circulates through the refrigeration system and absorbs and releases heat.

5. What are the different types of refrigeration applications?

Refrigeration systems are used in a wide variety of applications, including:

- Food preservation: Refrigeration systems are used to keep food fresh and prevent spoilage.

- Air conditioning: Refrigeration systems are used to cool buildings and other spaces.

- Industrial processes: Refrigeration systems are used to cool machinery and equipment in industrial processes.

- Medical applications: Refrigeration systems are used to store and preserve medical supplies and equipment.

6. What are the safety precautions that must be taken when working with refrigerants?

Refrigerants can be hazardous if not handled properly. The following safety precautions must be taken when working with refrigerants:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator.

- Work in a well-ventilated area.

- Handle refrigerants only in approved containers.

- Never smoke or use open flames around refrigerants.

- Be aware of the potential for refrigerant leaks and have a plan in place to respond to them.

7. What are the different troubleshooting techniques that can be used to diagnose refrigeration system problems?

The following troubleshooting techniques can be used to diagnose refrigeration system problems:

- Check the power supply to the system.

- Check the refrigerant levels.

- Check the compressor for proper operation.

- Check the condenser for cleanliness and airflow.

- Check the evaporator for cleanliness and airflow.

- Check the expansion valve for proper operation.

8. What are the different maintenance procedures that can be performed on refrigeration systems?

The following maintenance procedures can be performed on refrigeration systems:

- Check the refrigerant levels.

- Clean the condenser and evaporator coils.

- Lubricate the compressor.

- Check the expansion valve for proper operation.

- Check the electrical connections.

9. What are the different industry standards that apply to refrigeration systems?

The following industry standards apply to refrigeration systems:

- ASHRAE Standard 15: Safety Standard for Refrigeration Systems

- ANSI/IIAR Standard 2: Installation, Start-Up, and Maintenance of Refrigeration Systems

- EPA Section 608: Refrigerant Management Regulations

10. What are the future trends in refrigeration technology?

The following are some of the future trends in refrigeration technology:

- The use of natural refrigerants

- The development of more energy-efficient refrigeration systems

- The use of smart technology to improve the operation and maintenance of refrigeration systems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Refrigeration Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Refrigeration Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Refrigeration Mechanics are responsible for maintaining, installing, and repairing refrigeration systems, including those found in commercial buildings, industrial facilities, and private residences. Their duties include:

1. Troubleshooting and diagnosing problems

Troubleshooting and diagnosing problems in refrigeration systems is a core responsibility of Refrigeration Mechanics. They must be able to identify and correct any issues that may arise, ensuring that systems are functioning efficiently and effectively.

- Identifying the source of problems within refrigeration systems

- Utilizing diagnostic tools and techniques to accurately assess system performance

2. Installing and repairing refrigeration systems

Refrigeration Mechanics are also responsible for installing and repairing refrigeration systems, ensuring that they adhere to industry standards and regulations. They must have a strong understanding of refrigeration principles, as well as the ability to work with a variety of tools and materials.

- Installing refrigeration systems in accordance with manufacturer specifications and industry codes

- Repairing and replacing faulty components within refrigeration systems, including compressors, condensers, and evaporators

3. Maintenance and servicing refrigeration systems

In addition to installing and repairing refrigeration systems, Refrigeration Mechanics are also responsible for maintaining and servicing them. This includes regular inspections, cleaning, and lubrication of components, as well as monitoring system performance to ensure optimal efficiency.

- Performing regular maintenance and servicing on refrigeration systems to ensure optimal performance

- Lubricating moving parts and replacing worn or damaged components

4. Working with customers

Refrigeration Mechanics often work with customers to understand their needs and provide them with the best possible service. They must be able to communicate effectively, answer questions, and provide clear explanations of the work they are performing.

- Providing excellent customer service by addressing customer concerns and providing clear explanations

- Building strong relationships with customers based on trust and professionalism

Interview Tips

To prepare for your Refrigeration Mechanic interview, it is important to review the key job responsibilities and have a good understanding of your own skills and experience. Here are some tips to help you ace your interview:

1. Technical skills and experience

Highlight your technical skills and experience in refrigeration, including your knowledge of refrigeration principles, systems, and components. Be prepared to discuss specific projects you have worked on, as well as your troubleshooting and repair techniques.

- Review the job description and identify the specific technical skills and experience required

- Prepare examples of your past work that demonstrate your abilities and strengths

2. Communication and interpersonal skills

Refrigeration Mechanics must be able to communicate effectively with customers, colleagues, and supervisors. Emphasize your strong communication and interpersonal skills, and provide examples of how you have successfully worked with others to achieve common goals.

- Practice your communication skills by rehearsing your answers to common interview questions

- Demonstrate your active listening skills and ability to build rapport with others

3. Industry knowledge and trends

Staying up-to-date on industry knowledge and trends is important for Refrigeration Mechanics. Show that you are familiar with the latest technologies and innovations in refrigeration, as well as any industry regulations or standards that apply to your work.

- Research the refrigeration industry and identify emerging trends and technologies

- Attend industry events or webinars to stay abreast of the latest developments

4. Professionalism and work ethic

Refrigeration Mechanics must be professional and reliable, with a strong work ethic. Highlight these qualities in your interview by dressing appropriately, arriving on time, and maintaining a positive attitude throughout the interview process.

- Dress professionally and arrive on time for your interview

- Maintain a positive and enthusiastic attitude throughout the interview

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Refrigeration Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.