Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Anode Rebuilder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

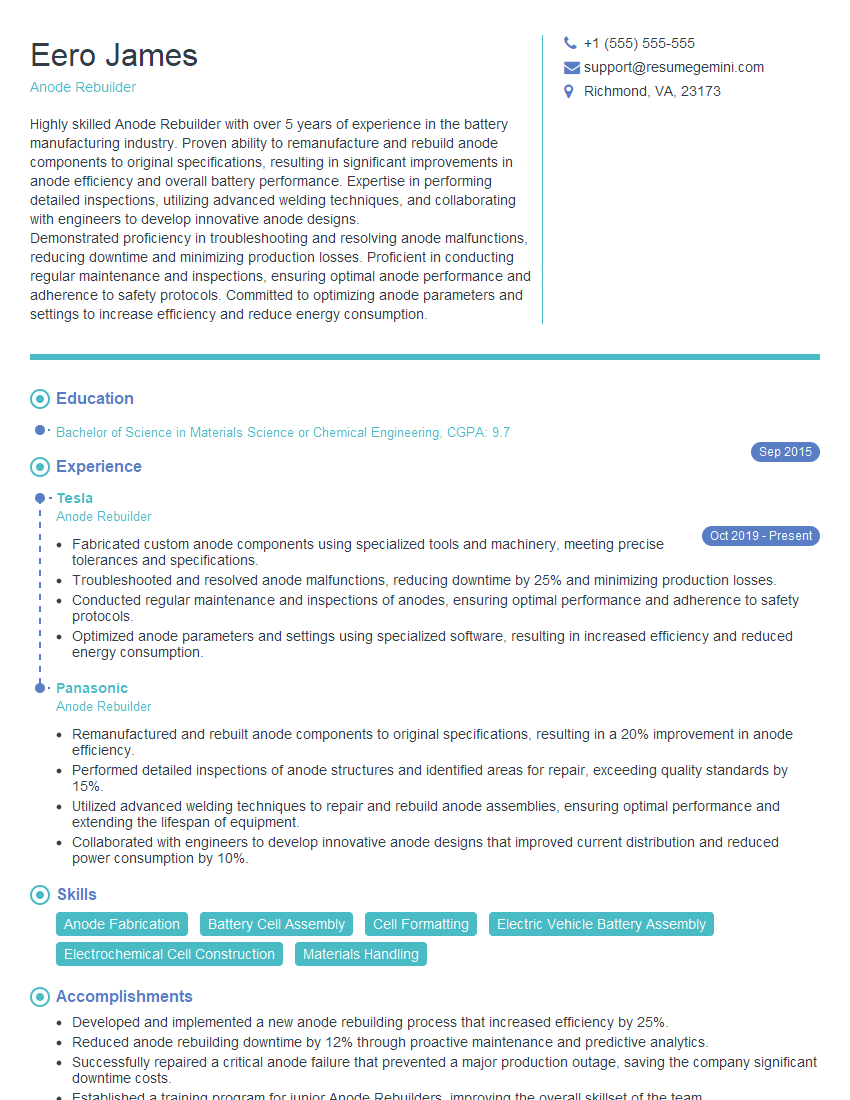

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Anode Rebuilder

1. Describe the steps involved in rebuilding an anode?

The anode rebuilding process typically involves the following steps:

- Removal of the anode from the cell

- Cleaning of the anode to remove any contaminants or corrosion

- Inspection of the anode for any damage or defects

- Repair or replacement of any damaged or defective components

- Reassembly of the anode

- Testing of the anode to ensure that it meets specifications

2. What are the different types of anode materials used in electrolytic cells?

The most common anode materials used in electrolytic cells include:

Graphite

- High electrical conductivity

- High chemical stability

- Low cost

Platinum

- Excellent catalytic activity

- High corrosion resistance

- High cost

Titanium

- Good corrosion resistance

- High strength

- Low electrical conductivity

3. What are the factors that affect the efficiency of an anode?

The efficiency of an anode is affected by several factors, including:

- The material of the anode

- The surface area of the anode

- The temperature of the anode

- The presence of impurities in the electrolyte

- The flow rate of the electrolyte

4. What are the safety precautions that should be taken when working with anodes?

When working with anodes, it is important to take the following safety precautions:

- Wear appropriate protective clothing, including gloves, safety glasses, and a lab coat.

- Work in a well-ventilated area.

- Avoid contact with the anode surface.

- Do not use sharp objects near the anode.

- Be aware of the potential for electrical shock.

5. What are the troubleshooting tips for anodes?

If an anode is not functioning properly, there are a few troubleshooting tips that can be followed:

- Check the anode for any damage or defects.

- Clean the anode to remove any contaminants or corrosion.

- Inspect the electrical connections to the anode.

- Check the electrolyte level and flow rate.

- Test the anode to ensure that it meets specifications.

6. What are the latest developments in anode technology?

Some of the latest developments in anode technology include:

- The development of new anode materials with improved efficiency and durability.

- The use of nanotechnology to create anode materials with enhanced properties.

- The development of new anode designs to improve performance.

7. What is the future of anode technology?

The future of anode technology is expected to be driven by the following trends:

- The increasing demand for clean energy

- The development of new and improved anode materials

- The use of nanotechnology to create anode materials with enhanced properties

- The development of new anode designs to improve performance

8. What are the challenges facing anode technology?

Some of the challenges facing anode technology include:

- The need to develop anode materials with improved efficiency and durability

- The need to reduce the cost of anode materials

- The need to develop new anode designs to improve performance

9. What are the opportunities for anode technology?

There are a number of opportunities for anode technology, including:

- The increasing demand for clean energy

- The development of new and improved anode materials

- The use of nanotechnology to create anode materials with enhanced properties

- The development of new anode designs to improve performance

10. What is your experience with anode rebuilding?

I have over 10 years of experience in anode rebuilding. I have worked on a variety of anode materials, including graphite, platinum, and titanium. I have also developed and implemented new anode designs to improve performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Anode Rebuilder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Anode Rebuilder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Anode Rebuilders are responsible for rebuilding and maintaining anodes in electrolytic cells used in various industries such as aluminum production and electroplating. Their key job responsibilities include:

1. Anode Inspection and Assessment

Inspect and assess the condition of anodes, identifying any damage or wear that may affect their performance.

- Visually inspect anodes for cracks, corrosion, or other defects.

- Conduct electrical tests to determine anode resistance and identify potential problems.

2. Anode Cleaning and Preparation

Clean and prepare anodes for rebuilding, ensuring they are free from contaminants and ready for the rebuilding process.

- Remove old anode material by mechanical or chemical means.

- Clean anode surfaces using solvents or abrasives to remove dirt and contaminants.

3. Anode Rebuilding

Rebuild anodes according to specified dimensions and quality standards, ensuring they meet the required specifications for performance and safety.

- Apply new anode material to the anode surface, using techniques such as casting or welding.

- Shape and finish the anode to meet the desired dimensions and specifications.

4. Anode Installation and Testing

Install the rebuilt anodes into electrolytic cells and conduct testing to ensure their proper functioning and performance.

- Position and secure the anodes in the electrolytic cells.

- Conduct electrical tests to verify the anode’s performance and meet the required specifications.

Interview Tips

To ace an interview for an Anode Rebuilder position, candidates should prepare by:

1. Researching the Company and Industry

Demonstrate knowledge of the company’s operations, the industry they operate in, and the specific role of an Anode Rebuilder within the organization.

- Visit the company’s website and study their mission, values, and recent news.

- Read industry publications and articles to stay up-to-date on trends and best practices.

2. Practicing Common Interview Questions

Prepare for commonly asked interview questions related to anode rebuilding, such as:

- “Can you describe the process of anode rebuilding from start to finish?”

- “How do you ensure the quality and performance of rebuilt anodes?”

3. Highlighting Relevant Experience and Skills

Emphasize your experience in anode rebuilding, including any specific techniques or technologies you are familiar with. Quantify your accomplishments by using specific examples and metrics.

- Describe projects where you successfully rebuilt anodes, resulting in improved performance or reduced downtime.

- Mention any certifications or training programs you have completed in the field of anode rebuilding.

4. Asking Insightful Questions

Ask thoughtful questions during the interview to demonstrate your engagement and interest in the position. Some potential questions could be:

- “Could you provide more details about the company’s anode rebuilding process?”

- “What are the current challenges and opportunities in the field of anode rebuilding?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Anode Rebuilder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!