Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bag Machine Adjuster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

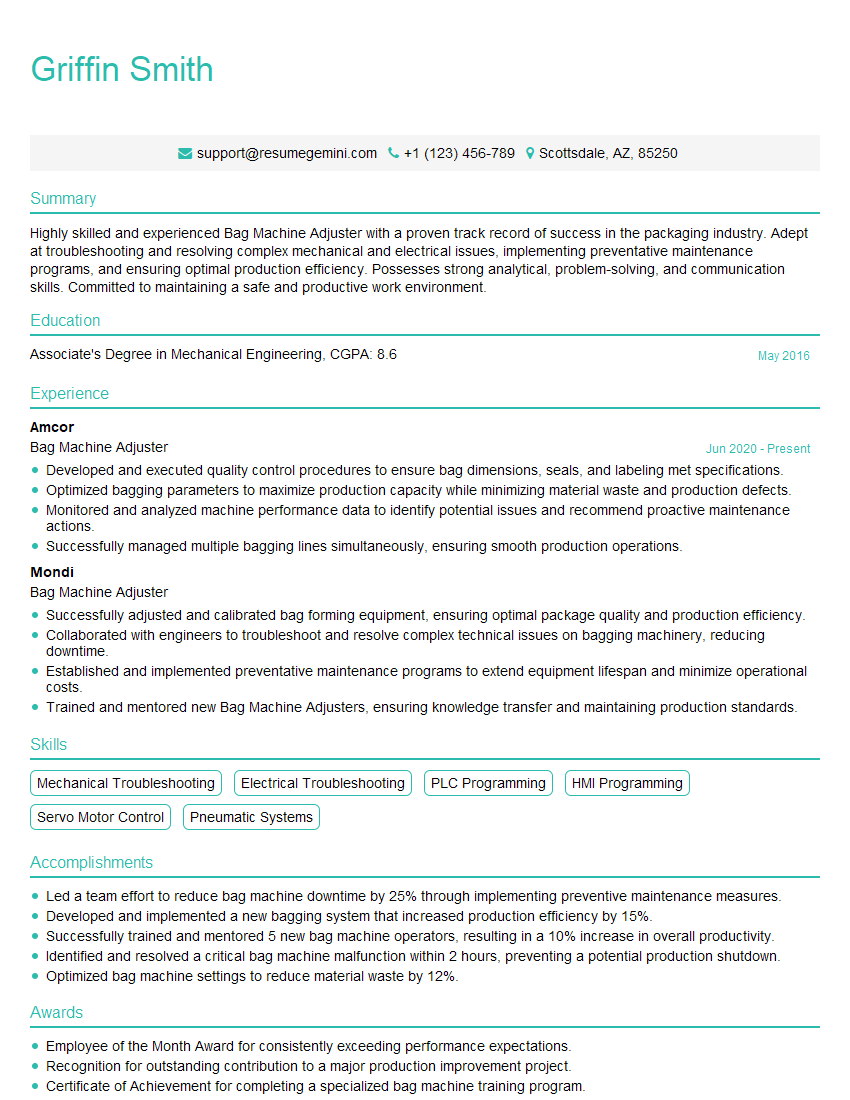

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bag Machine Adjuster

1. Describe the process of adjusting the timing of a bag machine?

To adjust the timing of a bag machine, I follow a systematic approach:

- Check the bag machine’s manual for specific instructions.

- Identify the timing adjustment mechanism, usually located on the machine’s control panel.

- Use adjustment tools, such as wrenches or screwdrivers, to make precise adjustments to the timing settings.

- Run test bags to verify the accuracy of the adjustment.

- Repeat the adjustment process until the bag machine is operating at the desired timing.

2. How do you troubleshoot a bag machine that is producing defective bags?

Defective Bag Types

- Misaligned or Torn Bags: Inspect feeding mechanism, sealing elements, and tension.

- Underfilled or Overfilled Bags: Check fill nozzle, sensors, and product supply.

- Leaking Bags: Examine sealing elements, bag material, and machine temperature.

Troubleshooting Process

- Identify the specific defect and potential causes.

- Inspect and test machine components, including sensors, actuators, and sealing units.

- Make necessary adjustments to settings, such as temperature, sealing pressure, or fill volume.

- Perform maintenance tasks, such as cleaning, lubrication, or replacing worn parts.

- Run test bags to verify the effectiveness of troubleshooting measures.

3. What is the importance of preventive maintenance for bag machines?

Preventive maintenance is crucial for bag machines because it:

- Reduces unplanned downtime and production interruptions.

- Extends the lifespan of the machine and its components.

- Improves bag quality and consistency.

- Identifies potential issues early on, preventing major breakdowns.

- Optimizes machine performance and efficiency.

4. Explain the different types of bag sealing methods and their applications?

- Heat Sealing:

- Uses heated elements to melt and bond bag material.

- Suitable for thermoplastic materials like polyethylene and polypropylene.

- Impulse Sealing:

- Applies short, intense heat pulses to seal the bag.

- Ideal for small bags, thin films, and laminated materials.

- Ultrasonic Sealing:

- Utilizes high-frequency sound waves to create friction and heat for sealing.

- Suited for airtight seals, complex bag shapes, and non-thermoplastic materials.

- Sewing or Stitching:

- Uses thread to sew or stitch the bag together.

- Provides strong and durable seals for heavier materials or special applications.

5. How do you ensure that the bag machine operates at optimal efficiency?

- Regularly conduct preventive maintenance checks.

- Monitor machine performance parameters, such as speed, temperature, and pressure.

- Optimize machine settings based on bag specifications and product characteristics.

- Use high-quality consumables, such as bag material and sealing elements.

- Train operators on proper machine operation and troubleshooting procedures.

6. Describe the safety protocols you follow when operating a bag machine?

- Wear appropriate personal protective equipment (PPE).

- Ensure the machine is properly grounded and isolated before working on it.

- Never reach into or touch moving parts.

- Follow lockout/tagout procedures when performing maintenance or repairs.

- Report any safety hazards or potential risks to supervisors immediately.

7. What techniques do you use to minimize product contamination during bagging?

- Clean and sanitize the bag machine and surrounding area regularly.

- Use dedicated bags for specific products to prevent cross-contamination.

- Inspect bags for tears or damage before filling.

- Minimize manual handling of products to reduce the risk of introducing contaminants.

- Implement quality control measures, such as using metal detectors or visual inspection, to check for foreign objects.

8. How do you handle emergency situations related to bag machine operation?

- Remain calm and assess the situation.

- Follow established emergency procedures, such as activating alarms and evacuating the area.

- Identify the source of the emergency and take immediate action to contain it.

- Contact supervisors and emergency responders if necessary.

- Document the incident and take steps to prevent future occurrences.

9. What are your thoughts on the latest advancements in bagging technology?

I am eager to embrace the latest advancements in bagging technology because:

- They enhance machine efficiency and productivity.

- They improve bag quality and reduce waste.

- They offer innovative solutions for specialized packaging needs.

- They facilitate remote monitoring and control of bagging operations.

- They contribute to sustainable packaging practices.

10. How do you stay updated with the best practices in bag machine operation and maintenance?

- Attend industry conferences and workshops.

- Read technical journals and online resources.

- Consult with manufacturers and suppliers.

- Engage in peer-to-peer knowledge sharing within the industry.

- Participate in training and certification programs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bag Machine Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bag Machine Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bag Machine Adjusters are responsible for maintaining and operating bagging machines in a variety of industries, ensuring that products are packaged accurately and efficiently.

1. Machine Set-up and Maintenance

Adjusts and maintains equipment to meet production requirements, troubleshooting and resolving technical problems to maintain optimal performance.

- Installs, assembles, and disassembles bagging machines.

- Calibrates and adjusts equipment to meet specifications.

2. Product Packaging

Operates machines to fill and seal bags with products, ensuring accurate filling and proper sealing to prevent contamination and maintain product quality.

- Adjusts machine speed, temperature, and other settings to optimize packaging efficiency.

- Inspects finished products to ensure they meet quality standards.

3. Material Handling

Loads and unloads raw materials and finished products from machines and ensures proper storage and handling practices.

- Maintains inventory levels and requests additional supplies as needed.

- Complies with safety regulations and ensures a clean and organized work area.

4. Quality Control

Monitors production processes and maintains quality standards, identifying and resolving any issues that may impact product quality.

- Conducts regular inspections to ensure equipment is operating correctly.

- Participates in quality improvement initiatives.

Interview Tips

Preparing thoroughly for a Bag Machine Adjuster interview can significantly increase your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s business, products, and industry trends. This demonstrates your interest and enthusiasm for the role.

2. Practice Your Technical Skills

Review your knowledge of bagging machine operations, maintenance, and troubleshooting. Be prepared to discuss your experience and demonstrate your technical proficiency.

3. Highlight Your Problem-Solving Abilities

Bag Machine Adjusters must be able to identify and resolve technical issues quickly and efficiently. Emphasize your analytical and problem-solving skills, providing examples of how you have handled challenges in the past.

4. Prepare for Safety Questions

Safety is paramount in any manufacturing environment. Be prepared to discuss your understanding of safety regulations and your role in maintaining a safe work environment.

5. Research the STAR Method

Many interviewers use the STAR method (Situation, Task, Action, Result) to evaluate candidates’ responses. Structure your answers accordingly to provide clear and concise examples of your experiences and accomplishments.

6. Be Punctual and Professional

Punctuality and professionalism are essential for any job interview. Arrive on time, dress appropriately, and maintain a positive attitude throughout the interview.

7. Ask Insightful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions related to the role, company, or industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bag Machine Adjuster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!