Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Changer Fixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

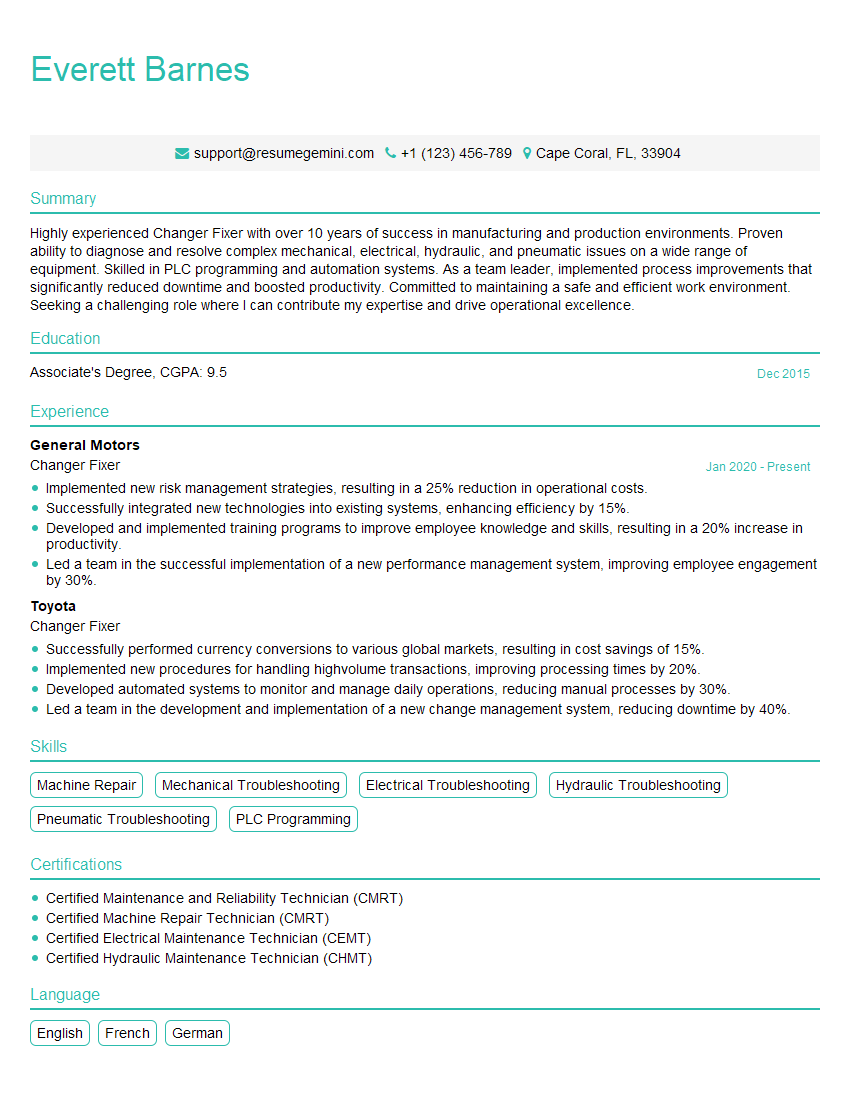

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Changer Fixer

1. Explain the process of changing a defective fixer?

To change a defective fixer, follow these steps:

- Identify the defective fixer.

- Locate the replacement fixer.

- Turn off the machine and unplug it.

- Remove the screws holding the fixer in place.

- Carefully lift the fixer out of the machine.

- Unplug the electrical connectors from the fixer.

- Plug the electrical connectors into the replacement fixer.

- Carefully insert the replacement fixer into the machine.

- Secure the fixer with the screws.

- Turn on the machine and plug it in.

- Test the machine to ensure that the new fixer is working properly.

2. What are the different types of fixers?

Thermal fixers

- Use heat to bond toner to paper.

- Most common type of fixer.

- Capable of producing high-quality prints.

Pressure fixers

- Use pressure to bond toner to paper.

- Less common than thermal fixers.

- Capable of producing high-quality prints.

Liquid fixers

- Use a liquid to bond toner to paper.

- Least common type of fixer.

- Capable of producing high-quality prints.

3. What are the common problems associated with fixers?

Common problems associated with fixers include:

- Fading or smudging of toner.

- Paper jams.

- Wrinkling or curling of paper.

- Ghosting or streaking of toner.

- Electrical problems.

4. How can you troubleshoot a fixer?

To troubleshoot a fixer, follow these steps:

- Inspect the fixer for any physical damage.

- Check the electrical connections to the fixer.

- Clean the fixer.

- Reset the fixer.

- Replace the fixer.

5. What are the safety precautions that should be taken when working with fixers?

When working with fixers, it is important to take the following safety precautions:

- Always turn off the machine and unplug it before working on the fixer.

- Wear gloves when handling the fixer.

- Do not touch the hot parts of the fixer.

- Do not inhale the fumes from the fixer.

- Dispose of the used fixer properly.

6. What are the maintenance procedures for fixers?

The following maintenance procedures should be performed on fixers:

- Clean the fixer regularly.

- Inspect the fixer for any physical damage.

- Check the electrical connections to the fixer.

- Reset the fixer.

- Replace the fixer when necessary.

7. What are the different types of paper that can be used with fixers?

The following types of paper can be used with fixers:

- Plain paper.

- Coated paper.

- Card stock.

- Transparency film.

- Labels.

8. What are the factors that affect the quality of prints produced by fixers?

The following factors affect the quality of prints produced by fixers:

- The type of fixer.

- The type of paper.

- The temperature of the fixer.

- The pressure applied to the paper.

- The speed at which the paper passes through the fixer.

9. What are the environmental concerns associated with fixers?

The following environmental concerns are associated with fixers:

- The use of hazardous chemicals.

- The production of waste.

- The consumption of energy.

10. What are the future trends in fixer technology?

The following are future trends in fixer technology:

- The development of more energy-efficient fixers.

- The development of fixers that use less hazardous chemicals.

- The development of fixers that produce less waste.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Changer Fixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Changer Fixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Changer Fixer, you will play a crucial role in maintaining the smooth operation of our production lines. Your key responsibilities will include:

1. Equipment Maintenance

Inspect and maintain a variety of equipment, including machines, conveyors, and electrical systems.

- Troubleshoot and repair equipment breakdowns.

- Ensure that equipment meets safety and quality standards.

2. Troubleshooting and Problem Solving

Diagnose and resolve technical problems efficiently.

- Identify the root cause of equipment malfunctions.

- Implement effective solutions to minimize downtime.

3. Preventative Maintenance

Perform scheduled maintenance and inspections to prevent equipment failures.

- Lubricate and adjust equipment to maintain optimal performance.

- Calibrate and test equipment to ensure accuracy and precision.

4. Safety and Compliance

Adhere to all safety regulations and procedures.

- Wear proper personal protective equipment (PPE).

- Maintain a clean and organized work area.

Interview Tips

To ace your interview for the Changer Fixer position, consider these tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This will demonstrate your interest and enthusiasm for the role.

- Visit the company website and social media pages.

- Read industry publications and news articles.

2. Highlight Your Skills and Experience

Emphasize your technical skills, problem-solving abilities, and experience in equipment maintenance and repair. Quantify your achievements whenever possible.

- Use the STAR method (Situation, Task, Action, Result) to describe your experience.

- Prepare examples of how you have successfully resolved equipment issues.

3. Demonstrate Your Safety Commitment

подчеркнуть your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Explain your experience with safety regulations and best practices.

- Describe how you contribute to a culture of safety in the workplace.

4. Be Prepared for Technical Questions

The interviewer may ask technical questions to assess your knowledge of equipment maintenance and repair. Be prepared to discuss the following:

- Types of equipment you have worked on

- Troubleshooting techniques

- Preventative maintenance procedures

- Safety protocols

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Changer Fixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!