Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Compressed Gas Plant Maintenance Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

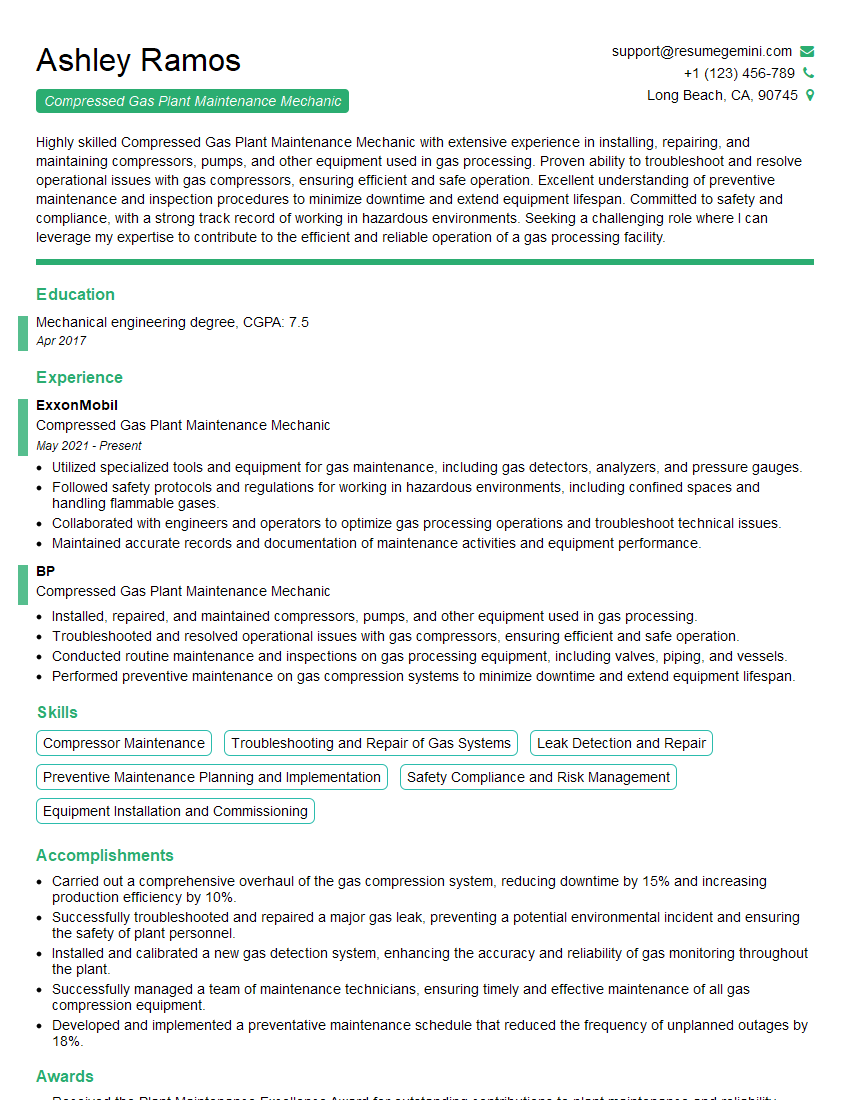

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compressed Gas Plant Maintenance Mechanic

1. What are the key components of a compressed gas system and what are their functions?

The key components of a compressed gas system include:

- Compressor: Compresses the gas to increase its pressure.

- Receiver: Stores the compressed gas.

- Piping and tubing: Transport the gas throughout the system.

- Valves: Control the flow of gas.

- Pressure gauges: Monitor the pressure of the gas.

- Safety devices: Prevent accidents, such as pressure relief valves and rupture discs.

2. Describe the different types of compressors used in compressed gas plants and explain their advantages and disadvantages.

Positive displacement compressors:

- Reciprocating compressors: High pressure, low flow rate

- Rotary screw compressors: Medium pressure, high flow rate

- Diaphragm compressors: Can handle corrosive gases

Dynamic compressors:

- Centrifugal compressors: High flow rate, medium pressure

- Axial compressors: Very high flow rate, low pressure

3. What are the common maintenance tasks performed on compressed gas equipment?

- Inspecting and cleaning components

- Lubricating moving parts

- Replacing filters

- Checking and adjusting pressure settings

- Troubleshooting and repairing faults

- Adhering to safety regulations

4. What are the safety precautions that must be followed when working with compressed gases?

- Wear appropriate personal protective equipment (PPE): Gloves, safety glasses, hearing protection.

- Never work alone.

- Ensure proper ventilation.

- Never smoke or ignite flames near compressed gas.

- Never use damaged equipment.

- Follow lockout/tagout procedures.

5. What are the different types of gas leaks and how can they be detected?

- Visible leaks: Can be detected visually by bubbling or escaping gas.

- Audible leaks: Can be detected by hissing or whistling sounds.

- Detectable leaks: Can be detected using gas detectors or leak detection sprays.

6. What are the steps involved in troubleshooting a compressor that is not starting?

- Check the power supply.

- Check the electrical connections.

- Check the oil level.

- Check the air filter.

- Check the pressure switch.

- Check the compressor valves.

7. What are the common causes of compressor vibration and how can it be reduced?

- Unbalanced rotors: Can be corrected by balancing the rotors.

- Misaligned coupling: Can be corrected by aligning the coupling.

- Loose bolts or foundations: Can be corrected by tightening the bolts or grouting the foundations.

- Resonance: Can be reduced by adding dampers or changing the operating speed.

8. What are the environmental regulations that apply to compressed gas systems?

- EPA Clean Air Act: Regulates the emission of air pollutants.

- OSHA Process Safety Management Standard: Regulates the safe operation of hazardous processes.

- Local and state regulations: May also apply to compressed gas systems.

9. What is your experience with preventive maintenance programs for compressed gas systems?

- I have developed and implemented preventive maintenance programs at [previous company].

- I have conducted inspections, lubricated components, and replaced filters on a regular basis.

- I have kept accurate records of all maintenance activities.

- I have monitored equipment performance and identified potential problems before they become major failures.

10. What are your career goals and how do you see this position contributing to them?

- I am seeking to advance my career in compressed gas maintenance.

- I believe that this position will provide me with the opportunity to develop my skills and knowledge in this field.

- I am eager to contribute to the safe and efficient operation of your compressed gas system.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compressed Gas Plant Maintenance Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compressed Gas Plant Maintenance Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Compressed Gas Plant Maintenance Mechanics play a vital role in ensuring the safe and efficient operation of compressed gas plants. Their key responsibilities encompass a wide range of maintenance and repair tasks, including:

1. Equipment Maintenance and Repair

Inspect, maintain, and repair a variety of compressed gas equipment, including compressors, tanks, pipelines, and valves.

2. Troubleshooting and Diagnostics

Troubleshoot and diagnose problems with compressed gas systems and equipment, identifying the root cause of issues and implementing appropriate solutions.

3. Predictive Maintenance

Conduct predictive maintenance inspections to identify potential problems before they escalate, ensuring the reliability and longevity of equipment.

4. Safety Compliance

Ensure compliance with all relevant safety regulations and standards, including OSHA and ASME, prioritizing the safety of employees, equipment, and the facility.

Interview Tips

To effectively prepare for an interview for a Compressed Gas Plant Maintenance Mechanic position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, mission, products, and industry trends. This demonstrates your interest in the organization and its operations.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills and experience in compressed gas systems maintenance and repair. Quantify your accomplishments to demonstrate your impact.

3. Prepare for Technical Questions

Review common technical topics related to compressed gas systems, such as compressor principles, tank design, and safety protocols. Prepare specific examples of your problem-solving abilities.

4. Demonstrate Safety Awareness

Highlight your understanding of safety regulations and practices in the compressed gas industry. Employers place a high value on safety-conscious individuals.

5. Practice Your Answers

Rehearse your answers to common interview questions. This will enhance your confidence and ensure that you present yourself professionally.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Compressed Gas Plant Maintenance Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Compressed Gas Plant Maintenance Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.